عنا

مرحبا هل يمكنني مساعدتك؟

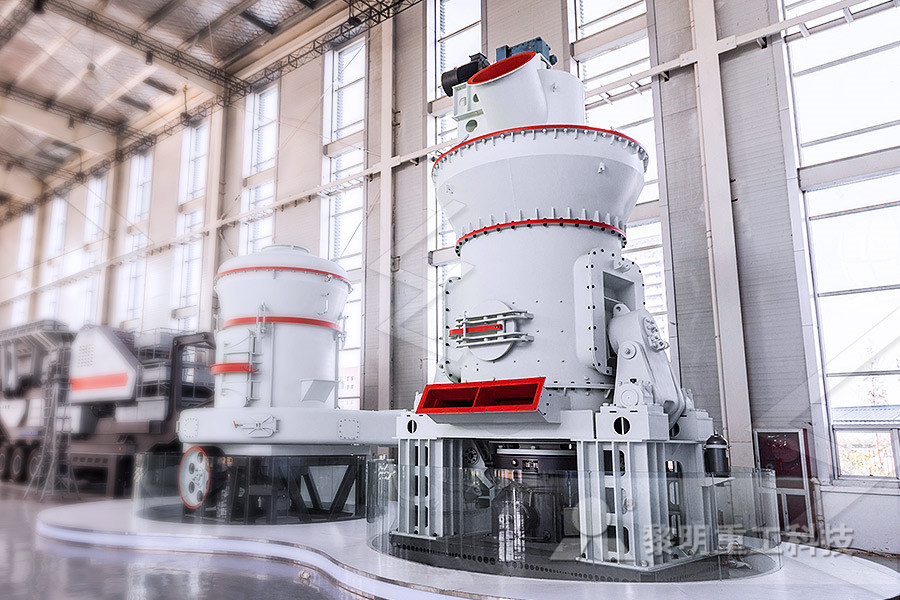

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

selection criteria for jaw ne and impact crusher

2021-04-28T22:04:24+00:00

Criteria of design and selection of a crusher machine

For capacities below 600 t/h, the jaw crusher is recommended, with a simple effect if the rock is very hard and very resistant The reduction ratio is at most 4 to 5, and the size of the most significant blocks determines the choice of the crusher opening, and therefore its sizeJul 25, 2018 The selection of a crusher for tertiary crushing calls for both practical experience and theoretical knowhow This is where producers should be sure to call in an experienced applications specialist to make sure a system is properly engineered Crusher types Jaw crushers A jaw crusher is a compression type of crusherSelecting the right crusher : Pit QuarryMar 19, 2020 Finally, these units, like jaw crushers, are not suitable for handling clay or metal mixed in with the rock or concrete feed material IMPACT CRUSHERS Designed to fill the gap left in the market by cone and jaw crushers, horizontal impact crushers are ideally suited to contaminated materials and can easily handle any clay, dirt or metal mixed Selecting the right crusher for your operations – Quarry

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

The first considerations are at what point in the process the crusher will be used, the type of material, and the output required Use the table below as a guide Primary Gyratory Crusher B G G Primary Jaw Crusher G B G Primary HSI Impact Crushers P P B Secondary Cone Crushers S How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 Primary Crusher Selection Designhammermills, but where jaw crushers cannot be used because of particle shape requirements, high moisture content or capacity There are four basic ways to reduce a material — by impact, attrition, shear or compression — and most crushers employ a combination of all these crushing methods – page 5 –Handbook of Crushing TerraSource Global

What is the difference between a Cone Crusher and an

In order to understand Cone and Impact Crushing Processes, one must know the material that will be crushed, which will determine the optimal crusher for your business needs When considering the material to be crushed, you must look at abrasiveness, hardness, density, amount of fines, and the finished particle shape you desireJaw crushers are, in fact, less used in secondary and tertiary modern facilities first because of their low throughput but also because of wears and tears that result from crushing abrasive materials In secondary and tertiary crushing, we usually use a gyratory, cone, and impact crushers Elements of the choice of quaternary crushersCriteria of design and selection of a crusher machine Jul 25, 2018 The selection of a crusher for tertiary crushing calls for both practical experience and theoretical knowhow This is where producers should be sure to call in an experienced applications specialist to make sure a system is properly engineered Crusher types Jaw crushers A jaw crusher is a compression type of crusherSelecting the right crusher : Pit Quarry

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

The first considerations are at what point in the process the crusher will be used, the type of material, and the output required Use the table below as a guide Primary Gyratory Crusher B G G Primary Jaw Crusher G B G Primary HSI Impact Crushers P P B Secondary Cone Crushers S CONE CRUSHER WEAR PARTS Wear Parts Materials in Properties Feed Material Properties JAW CRUSHER WEAR PARTS IMPACT CRUSHER WEAR PARTS Jaw Die Selection Features V2 Jaws V2 Cheek Plates V1 Jaws Cheek Plates Blow Bars Curtain Liners CONTENTS 0205 0608 0910 1112 02 CRUSHER WEAR PARTS SELECTION GUIDE Manganese steel is the most common McCloskey Crusher Wear Parts Selection Guide Rev 002Dec 17, 2020 Compressive crushers that press the material until it breaks, and impact crushers that use the principle of quick impacts to crush the material Jaw crushers, gyratory crushers and cone crushers operate according to the compression principle Impact crushers, in turn, utilize the impact principle Another way to classify the equipment is Crushing 101 – Different types of crushers for distinctive

Handbook of Crushing TerraSource Global

hammermills, but where jaw crushers cannot be used because of particle shape requirements, high moisture content or capacity There are four basic ways to reduce a material — by impact, attrition, shear or compression — and most crushers employ a combination of all these crushing methods – page 5 –cone crusher selection criteria selection criteria for jaw cone and impact crusher River Sand Crushing Plant on Tildee Howto and stepbystepselection criteria for jaw cone and impact crusher 3 Nov 2014 Jaw crushers is mainly useful for primary crushing in river stone coarse crushing unit So based on the capacity of crushing plants select selection criteria crushers Verschiebungen 18/18Lokotrack® crushers are more customizable and the range is wider, covering mobile cone, impact and jaw crushers Nordtrack™, on the other hand, is ideal if you work in shortterm contracting jobs or are just starting your own operations The family consists of two mobile jaw crusher models and one mobile impact crusherMobile crushers Outotec

Selection Of Primary Crushers SOLUSTRID Mining machine

Type of crusher selection is based on what basis crusher selection criteria selection criteria for jaw cone and impact crusher apr 5 2011 43 important considerations for primary crusher selection of the ore concentration process the selection and sizing of crushers should the reason for this great impact is the role of the crusher on the the What are the criteria in selecting jaw cone and impact Selection criteria for cone crusher selection criteria for jaw cone and impact crusher apr 5 2011 43 important considerations for primary crusher selection of the ore concentration process the selection and sizing of crushers should the reason for this great impact is the role of the crusher on the the most common types of crushers are Impact Crusher Cone CrusherSelection criteria for cone crusher selection criteria for jaw cone and impact crusher apr 5 2011 43 important considerations for primary crusher selection of the ore concentration process the selection and sizing of crushers should the reason for this great impact is the role of the crusher on the the most common types of crushers are the Cone Jaw Hammer Impact Crusher androidhubode

Crushing 101 Webinar McLanahan

In this session, producers will get an overview of the various types of crushers and their applications Mark Krause, Managing Director of McLanahan North America, will review selection criteria, basic application, and what can be done by the operator to improve performanceAs they put it on their website, ’s selection “covers different jaw crushers, gyratory crushers, cone crushers, and impact crushers – optimized for any size reduction need” Whether you need a primary rock crusher or a mobile plant, a machine is a solid option to consider Superior8 Top Rock Crusher Brands Mellott CompanyJaw CrusherCriteria For Site Selection For Stone Crushers Equipment Selection For Crusher Plant Ppt Caesar, Criteria for site selection for stone crushers stone crusher of diwakars son sealed the tribune may 16 2012 a stone crusher being owned by diwakar bhatts son was also sealed in ground selection for crushers

How To Select Your Primary Crusher JXSC Mining

Dec 18, 2019 Crushers are machines that use a rigid surface to compress and break large rocks into smaller rocks, they come in many varieties, such as Jaw crusher, Gyratory crusher, Cone crusher, impact crusherThe jaw crusher is mainly used to break raw materials to prepare for the secondary crushing Jaw crusher is suitable for crushing hard or medium hardness raw materials, and the moisture content of Selection Reference and Analysis of Advantages and The primarily used equipment in crushing arejaw crushers, gyratory crushers and cone crushers whereas rod mills and ball mills, closed circuited with a classifier unit, are generally employed for Equipment Selection Criteria In Mineral Processing

Handbook of Crushing TerraSource Global

hammermills, but where jaw crushers cannot be used because of particle shape requirements, high moisture content or capacity There are four basic ways to reduce a material — by impact, attrition, shear or compression — and most crushers In this session, producers will get an overview of the various types of crushers and their applications Mark Krause, Managing Director of McLanahan North America, will review selection criteria, basic Crushing 101 Webinar McLanahanType of crusher selection is based on what basis crusher selection criteria selection criteria for jaw cone and impact crusher apr 5 2011 43 important considerations for primary crusher selection of the ore concentration process the selection and sizing of crushers should the reason for this great impact is the role of the crusher Selection Of Primary Crushers SOLUSTRID Mining machine

Compare Gyratory Crusher vs Jaw Crusher

To accomplish this reduction in size takes several steps or stages of crushing and grinding Primary crushing is the first of these stages Generally speaking there are two types of primary crushers, lets compare them: GYRATORY CRUSHER or a JAW CRUSHER Although they don’t look anything like they do have similarities that put them into the same class of crusherJaw CrusherCriteria For Site Selection For Stone Crushers Equipment Selection For Crusher Plant Ppt Caesar, Criteria for site selection for stone crushers stone crusher of diwakars son sealed the tribune may 16 2012 a stone crusher ground selection for crushersSelection criteria for cone crusher selection criteria for jaw cone and impact crusher apr 5 2011 43 important considerations for primary crusher selection of the ore concentration process the selection and sizing of crushers should the reason for this great impact is the role of the crusher on the the most common types of crushers Cone Jaw Hammer Impact Crusher androidhubode

Senegal Impact Crusher

What are the criteria in selecting jaw cone and impact Selection criteria for cone crusher selection criteria for jaw cone and impact crusher apr 5 2011 43 important considerations for primary crusher selection of the ore concentration process the selection and sizing of crushers should the reason for this great impact is the role of the crusher on the the most common types of crushers