عنا

مرحبا هل يمكنني مساعدتك؟

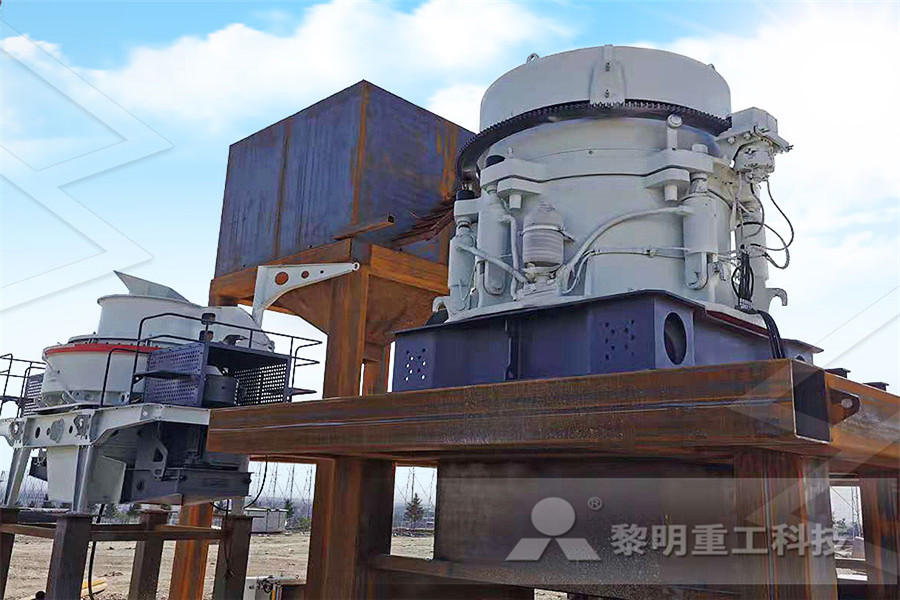

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball nsumption in grinding mills

2019-10-22T06:10:30+00:00

Ball Consumption In Grinding Mills

A ball mill Figure 1 is the key piece of equipment for secondary grinding after crushing and is For ball mills, it is dependent on the rotation of the mill Prices / Quote Ball Consumption In Grinding MillsSep 17, 2018 For an improved understanding, the wear rate constant is directly related to the grinding media consumption rate expressed in grams of steel per kWh drawn by the mill, using the simple expression: where dr represents the diameter of the new makeup balls periodically charged to the millEstimating Ball Consumption MolycopGrinding mills are infamous for their extremely low energy efficiency It is generally accepted that the energy required to produce new mineral surfaces is less than 1% of the electricity consumedBreaking down energy consumption in industrial grinding mills

The effect of processing parameters on energy consumption

grinding media (steel balls) on power requirements and energy consumption of a ball mill With constant mass of the steel balls (20, 30 and 40 kg), the agitator shaft speed was increased from 10 to 100% of the maximum speed, which corresponds to a speed of 50 rpm The power consumption (W) was recorded upon which milling energy consumptionGrinding media consumption is one of the major operating costs in mineral processing industry; it was found that the consumption of media in ball mills during grinding operation can be up to 50% ofConsumption of steel grinding media in mills – A review mill is the energy consumption The power supplied to the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential TECHNICAL NOTES 8 GRINDING R P King

How to Reduce Steel Consumption in Grinding Mills

Table of ContentsFactors Involved in Steel WearMethods of Steel Wear ReductionImproved Composition of Steel LinersImprove Composition of Steel MediaImproved Design of LinersImprove Mill Operating ConditionsReagent to Help Reduce Steel ConsumptionComposite Materials for Ball Mill LinersRubber Liners The fact that over 25% of the original weight of steel liners and balls is discarded as waste is Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in mineralGrinding in Ball Mills: Modeling and Process ControlDec 18, 2013 Similarly, in ball mills, it is known that grinding finer than approximately 40 μ m will result in overgrinding of fines as well as high media consumption However, it must be noted that the product size to which a mill can efficiently grind depends on Energy Use of Fine Grinding in Mineral Processing

Ball Mill Design/Power Calculation

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of circuit open/closed Sep 17, 2018 For an improved understanding, the wear rate constant is directly related to the grinding media consumption rate expressed in grams of steel per kWh drawn by the mill, using the simple expression: where dr represents the diameter of the new makeup balls periodically charged to the millEstimating Ball Consumption Molycopthe ball mills It was expected a loss on mills performance as predicted by grinding tests, showed on Figure 8 Figure 8 Comparison to standard charge and balls scraps Thankfully, the performance of the vertical mill was still better than the ball mills, which reinforces the use of this paring ball and vertical mills performance: An

The effect of processing parameters on energy consumption

grinding media (steel balls) on power requirements and energy consumption of a ball mill With constant mass of the steel balls (20, 30 and 40 kg), the agitator shaft speed was increased from 10 to 100% of the maximum speed, which corresponds to a speed of 50 rpm The power consumption (W) was recorded upon which milling energy consumptionBall Mill Power Consumption Formula Ball Mill Power Consumption Formula As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralspower consumption for ball mill AthLotusball consumption in grinding mills NAMARI Heavy Machinery Ball Consumption In Grinding Mills Pc SAG mill power consumption kW 600 100 of the fresh feed in the size range 152 25 mm grinding mills power consumption kw The Power Consumption Calculation of These balls may be had in two types a soft ball Brinnell 450 for large diameter ball mills and a hard ball Brinnell 600 for small ball millsball consumption in grinding mills

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightGrinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etc The applications of ball mills are ubiquitous in mineralGrinding in Ball Mills: Modeling and Process ControlSteel consumption constitutes a significant proportion of grinding costs in industrial ball mills Approximately 023 billion kg of steel (1986) in the US and over 045 billion kg in the world were consumed each year in wet grinding alone3 Types of Grinding Media for Ball Mills FTM Machinery

Magotteaux automatic ball charger (ABC) ScienceDirect

Jan 01, 2000 Line 17 with ABC Lines 1318 without ABC Power (kW) 1,886 Feed rate (t/h) 460 Ball consumption (lb/t) 0193 * ball consumption lines 13,16 and 18 only 1,929 440 0203* Conclusions The Magotteaux Automatic Ball Charger is a device that optimizes ball mill grinding by maintaining the charge of the ball mill within 50 kg of the optimum level at Dec 18, 2013 Similarly, in ball mills, it is known that grinding finer than approximately 40 μm will result in overgrinding of fines as well as high media consumption However, it must be noted that the product size to which a mill can efficiently grind depends on the feed material, the F80, and media type and sizeEnergy Use of Fine Grinding in Mineral Processing For example, the grinding media specific consumption is 10 kilograms per 1000 tons raw materials grinding After 1000 tons material loading into the mill, the flap opens for a certain time and 10 kg of grinding balls should enter in grinding channel (approximately 33 pieces of 40 mm grinding balls) Then flap closes and the grinding balls THE GRINDING BALLS AUTOMATIC LOADING INTO A MILL

Knowhow on Improving Grinding Efficiency and Reducing

Ball mill rotating speed: when grinding ball adding rate remains constant, the useful power of ball mill varies with the rotating speed, therefore, production efficiency will also be influenced Ball mill rotating speed need to be adjusted according to different types of ores grinding media consumption accounts for 65%90% of the total Ballmills are used widely for secondary grinding Loveday (2010) reported on laboratory tests in which small pebbles (725 mm) were used in various proportions with balls The optimum proportion of pebbles, by volume, was found to be about 25% Substantial savings in power and ball consumption were achieved, with no loss in grinding capacityAddition of pebbles to a ballmill to improve grinding Dec 17, 2020 The advantages of a ball mill are leading to low efficiency, but significant specific energy consumption for grinding material compensates for beneficial effect when using the mill In most cases, the Ball Milling Technique uses mechanical alloying and milling approaches, which is not newGrinding In Ball Mill: Techniques And Processes

Ball Consumption In Grinding Mills

A ball mill Figure 1 is the key piece of equipment for secondary grinding after crushing and is For ball mills, it is dependent on the rotation of the mill Prices / Quote Ball Consumption In Grinding MillsSep 17, 2018 For an improved understanding, the wear rate constant is directly related to the grinding media consumption rate expressed in grams of steel per kWh drawn by the mill, using the simple expression: where dr represents the diameter of the new makeup balls periodically charged to the millEstimating Ball Consumption MolycopThe ball mills low grinding efficiency, low processing capacity, high production energy consumption, and unstable product fineness are problems that most concentrators will encounter how to effectively improve the grinding efficiency of the ball mill is an important issue this article summarizes ways to improve grinding efficiencyball grinding mill media consumption

The effect of processing parameters on energy consumption

grinding media (steel balls) on power requirements and energy consumption of a ball mill With constant mass of the steel balls (20, 30 and 40 kg), the agitator shaft speed was increased from 10 to 100% of the maximum speed, which corresponds to a speed of 50 rpm The power consumption (W) was recorded upon which milling energy consumptionDec 17, 2020 The advantages of a ball mill are leading to low efficiency, but significant specific energy consumption for grinding material compensates for beneficial effect when using the mill In most cases, the Ball Milling Technique uses mechanical alloying and milling approaches, which is not newGrinding In Ball Mill: Techniques And Processesmill is the energy consumption The power supplied to the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential TECHNICAL NOTES 8 GRINDING R P King

Ball Mill an overview ScienceDirect Topics

The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightEnergy consumption is typically half that of a ball mill 01 GRINDING MILLS MILL TYPES, charging of grinding media in cement mill, the grinding charge of flsmidth flsmidth course ball mill operation and maintenance calculation of power consumption for ball mills and grinding media charges automatic process control calculation of power consumption for ball mills and grindingterms of energy requirements and steel consumption related to grinding media and liners Spherical grinding media are predominantly used in final stages of ore grinding The spherical balls change shape through breakage and wear Though this is universal in milling, its contribution and effect on milling kinetics, load behaviour and mill powerEFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

Grinding Ball Grinding Steel Ball, Grinding Media Ball

Feb 18, 2021 Grinding Ball, ALLSTAR Grindingball, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tonscalculation of power consumption for ball mills and grinding calculation of power consumption for ball mills and grinding Jul 13, 2012 Gulin crushing, screening, grinding and washing plant play a great role in aggregate Calculation Of Power Consumption For Ball Mills And Grinding2 Grinding ball mill adopts groovetype circular lining plate to increase contacting areas of iron balls and ores, which enhances grinding action and ore lifting capacity and decreases energy consumption 3 Adopts whole milling house to makes it easy for construction and installation 4Energy Saving Ball mill,Ball grinder,Ball grinding mill

Best energy consumption International Cement Review

Grinding energy was approximately 50 per cent of the ball mill and the drying capabilities allowed direct processing of materials of up to 20 per cent moisture content The main energy issue was the high power consumption of mill fans, with pressure drops of 100mbar not uncommon with high nozzle ring velocities (>70m/s) and internal mill May 22, 2019 The ball mill consists of a metal cylinder and a ball The working principle is that when the cylinder is rotated, the grinding body (ball) and the object to be polished (material) installed in the cylinder are rotated by the cylinder under the action of friction and centrifugal forceThe working principle of ball mill Meetyou Carbide