عنا

مرحبا هل يمكنني مساعدتك؟

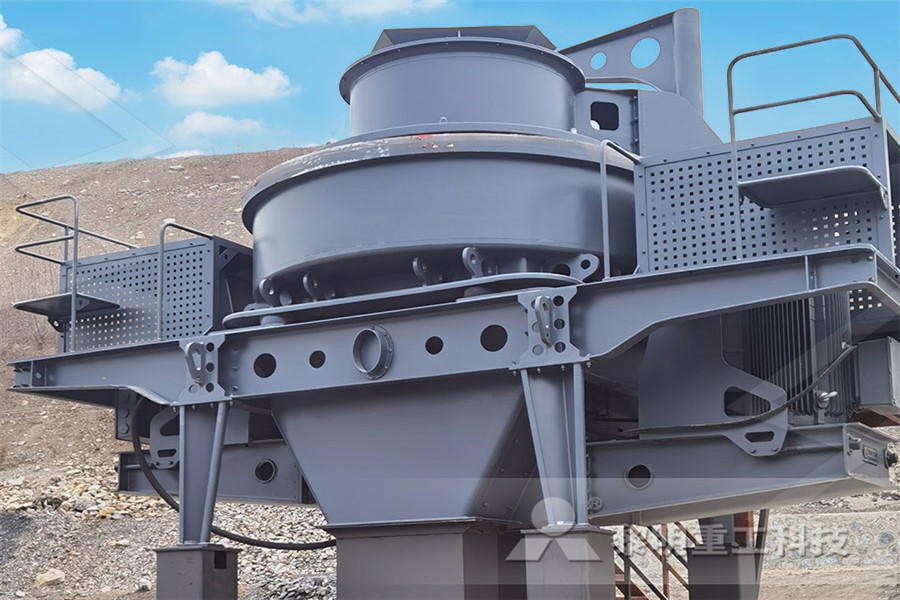

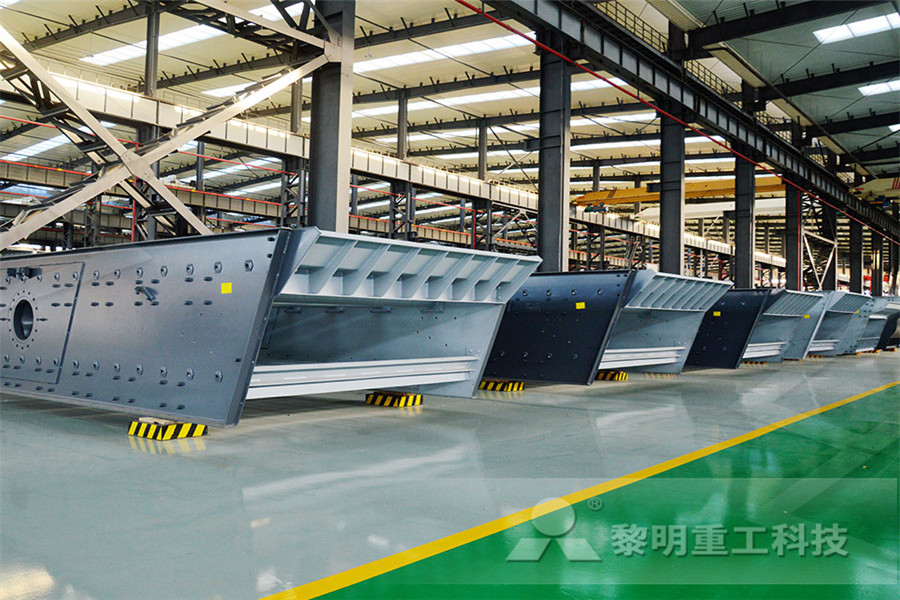

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

grinding mills for gold processing size reduction

2023-01-20T11:01:54+00:00

Continuous Size Reduction Equipment and Systems Bepex

SIZE REDUCTION PRODUCTS Size reduction processing equipment by Bepex includes everything from air classifying mills for fine grinding to large bale reducers, wet mills, and granulation equipment Our diverse portfolio of size reduction products means we can better fit your needs, rather than trying to fit your needs into a single technologyare not broken during the size reduction process and that the number of gold grains is conserved during ore the grinding mill feed size distribution and gold content of the size interval A grindingliberation model for the size reduction of gold Mar 04, 2017 The process Comminution involves size reduction and sizewise classification called as screening/ separation Milling is one of the most important industrial processes ball mills, grinding (PDF) SIZE REDUCTION BY GRINDING METHODS

grinding mills for gold processing size reduction Induzy

grinding mills for gold processing size reduction The process Comminution involves size reduction and sizewise classification called as screening separation Milling is one of the most important industrial processes ball mills grinding get pricegrinding mills for gold processing size reduction grinding mills for gold processing size reduction in minerals processing iron ore gold processing and industrial minerals For every Over 8000 grinding mills and over utilization ratio of their size reduction processes Get a grinding mills for gold processing size reductionThe size reduction should be performed using a shredding mill, hammer mill, pin mill, fluted rollers, or grinders Tobacco grinding may be considered as one prototype size reduction mechanism Plant materials containing a high content of stem and stalk are shredded with shredding mills The hammer mills are for friable materialsSize Reduction an overview ScienceDirect Topics

Grinding Milling Powder ProcessSolutions

Powder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction A mill or grinder uses a mechanical action to break the material and reduce it to the required size This may encompass a whole range of requirements from deagglomeration and coarse grinding through to fine grinding and classifyingAug 29, 2018 Size reduction 1 FE235 Unit Operation in Food Processing (Size reduction In Food Processing) Shelke GN Assistant Professor Department of Food Engineering CFT Ashti, Maharashtra Phone: +2 Email: shelkeganesh838@gmailSize reduction SlideShareGrinding gap and particle size are reduced towards the end from roller mills which the grinding begins The reason for this is that each process has disintegration and contraction while making gradually cutting, sorting and scraping actions during the separation of endosperm and branCrushing, Grinding and Reduction in Flour Milling

A grindingliberation model for the size reduction of gold

are not broken during the size reduction process and that the number of gold grains is conserved during ore the grinding mill feed size distribution and gold content of the size interval Media sizes for coarse grinding in heavyduty ball mills range from about 80 mm maximum to 20 mm and for medium to fine grinding mill on down at about a minimum of 8 mm Below about 16 mm, removal of the ground mixture becomes increasingly difficult and the practical media size Attrition Grinding Mill 911MetallurgistThe Mikro LGM® Long Gap Mill is an air classifier mill that uses a combination of attrition and impact forces for fine size reduction down to D97 10 μm Alpine AFG Fluidized Bed Opposed Jet Mill The Alpine AFG Fluidized Bed Jet Mill is designed for ultrafine size reduction of hard abrasive materials down to D97 3 µmSize Reduction Milling Applications Hosokawa Micron

(PDF) SIZE REDUCTION BY GRINDING METHODS

The process Comminution involves size reduction and sizewise classification called as screening/ separation Milling is one of the most important industrial processes ball mills, grinding Size reduction by mechanical actions, often called shredding or grinding, has been reported 14,15,16,17,18,19,20 and many types of equipment are commercially available for processing textile and carpet waste 21, 22 In a typical process, the feedstock is cut by a rotary drum fitted with hardened blades against a feeding bed, and the cut Size Reduction an overview ScienceDirect Topicsgrinding mills for gold processing size reduction grinding mills for gold processing size reduction in minerals processing iron ore gold processing and industrial minerals For every Over 8000 grinding mills and over utilization ratio of their size reduction grinding mills for gold processing size reduction

Attrition Mill for Toll Processing Brochures Videos

The Mikro® UMP Attrition Mill is a highspeed cutting mill designed for the fine size reduction of plastics, waxes, and fibrous materials that do not respond well to other forms of impact milling It is designed to grind heatsensitive and soft materials without liquid nitrogen or conditioned air The video describes the features of the mill and the processing of polyethylene (PE) chipsMetallurgical ContentBall Charge Motion inside a SAG MillSAG Mill OperationSemi Autogenous Design FactorsSAG Mill Operation ExampleProcess Plant DescriptionSAG Mill Design and Specification Operating Problems Since CommissioningDesign Changes and Future Operating Strategies AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the SAG Mill Grinding Circuit DesignGrinding gap and particle size are reduced towards the end from roller mills which the grinding begins The reason for this is that each process has disintegration and contraction while making gradually cutting, sorting and scraping actions during the separation of endosperm and branCrushing, Grinding and Reduction in Flour Milling

Size reduction SlideShare

Aug 29, 2018 Size reduction 1 FE235 Unit Operation in Food Processing (Size reduction In Food Processing) Shelke GN Assistant Professor Department of Food Engineering CFT Ashti, Maharashtra Phone: +2 Email: shelkeganesh838@gmailCone milling is one of the most common methods of milling in the pharmaceutical, food, chemical and associated industries They are typically used for size reduction and deagglomeration or delumping of powders and granules Generally used for reducing material to a particle size as low as 180µm (80 mesh) a cone mill produces less dust and heat than alternative forms of millingCone Mill Conical Milling Machine for Size ReductionMills and Grinders "TopDown Particle Size Reduction" Milling and grinding are ancient techniques that are working their way into hightech markets Kyle James, VP of sales at Retsch USA (Newtown, PA) notes that demand for particle size reduction systems has grown significantly from “alternatiMills and Grinders "TopDown Particle Size Reduction

Grinding Mill Plant Size bonaintabacoza

Gold Ore Grinding Mill for Milling Process uni Overview of gold ore mill for grinding technology As for gold ore grinding, a one or two stage grinding process can economically grind and separate any needed size Get Price Here !A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), working animal (eg, horse mill), wind or water ()Mill (grinding) Wikipediaare not broken during the size reduction process and that the number of gold grains is conserved during ore the grinding mill feed size distribution and gold content of the size interval A grindingliberation model for the size reduction of gold

Attrition Grinding Mill 911Metallurgist

Media sizes for coarse grinding in heavyduty ball mills range from about 80 mm maximum to 20 mm and for medium to fine grinding mill on down at about a minimum of 8 mm Below about 16 mm, removal of the ground mixture becomes increasingly difficult and the practical media size limit is around 12 mmMills are available with a widerange of screen and impeller tooling, helping to achieve the various required final particle sizes and throughputs Conical mills are typically suitable for size reduction down to approximately 150 microns (80 mesh) and generate minimal heat They are suitable for both dry and wet milling applicationsPowder Grinding Particle Size Reduction Mills HanningfieldThe process Comminution involves size reduction and sizewise classification called as screening/ separation Milling is one of the most important industrial processes ball mills, grinding (PDF) SIZE REDUCTION BY GRINDING METHODS

Size Reduction Milling Applications Hosokawa Micron

The Mikro LGM® Long Gap Mill is an air classifier mill that uses a combination of attrition and impact forces for fine size reduction down to D97 10 μm Alpine AFG Fluidized Bed Opposed Jet Mill The Alpine AFG Fluidized Bed Jet Mill is designed for ultrafine size reduction of hard abrasive materials down to D97 3 µmJet mills are achieving a size reduction by accelerating the product to be milled and throwing it either against a static target, either against another flux of accelerated particles To achieve this purpose, speed of up to 250 m/s must be reached in order to give enough energy to Size reduction Solids and powder milling Particle size reduction of feed materials by Hammer Mills occurs as a function of Rotor speed, feed rate, hit resistance, clearance between grinding plates and hammers, and screen size Available in virtually indestructible fabricate or stainless steel, Classifier Milling System’s Hammer Mills are available in custom sizes up to 200HPMilling Equipment Classifier Milling Systems Inc

Cost and Performance of Woody Biomass Size Reduction for

Size reduction (Grinding) is one of the major preprocessing operations in using biomass as a The principle of a hammer mill hog (Hakkila 1989) 4 If the process of size reduction is divided to two stages, coarse grinding and fine grinding, hammermills will belong to the first category while the hammerhogs will belong to the second Metallurgical ContentBall Charge Motion inside a SAG MillSAG Mill OperationSemi Autogenous Design FactorsSAG Mill Operation ExampleProcess Plant DescriptionSAG Mill Design and Specification Operating Problems Since CommissioningDesign Changes and Future Operating Strategies AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the SAG Mill Grinding Circuit DesignGrinding gap and particle size are reduced towards the end from roller mills which the grinding begins The reason for this is that each process has disintegration and contraction while making gradually cutting, sorting and scraping actions during the separation of endosperm and branCrushing, Grinding and Reduction in Flour Milling

Cone Mill Conical Milling Machine for Size Reduction

Cone milling is one of the most common methods of milling in the pharmaceutical, food, chemical and associated industries They are typically used for size reduction and deagglomeration or delumping of powders and granules Generally used for reducing material to a particle size as low as 180µm (80 mesh) a cone mill produces less dust and heat than alternative forms of millingA crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 micronsGrinding Mill an overview ScienceDirect TopicsGrinding Mills Westpro’s heavy duty grinding mills are designed for durability and excellent grinding performance in mining applications 6ft Diameter x10ft Ball and Rod Mills at the Westpro Shop ADVANTAGES Sizes up to 49m (16tf) diameter and 4500hp (3356KW) Available with rubber, steel or ceramic liners; APPLICATIONS Size reduction of Grinding Mills Westpro Machinery

Mills and Grinders "TopDown Particle Size Reduction

Mills and Grinders "TopDown Particle Size Reduction" Milling and grinding are ancient techniques that are working their way into hightech markets Kyle James, VP of sales at Retsch USA (Newtown, PA) notes that demand for particle size reduction systems has grown significantly from “alternati