عنا

مرحبا هل يمكنني مساعدتك؟

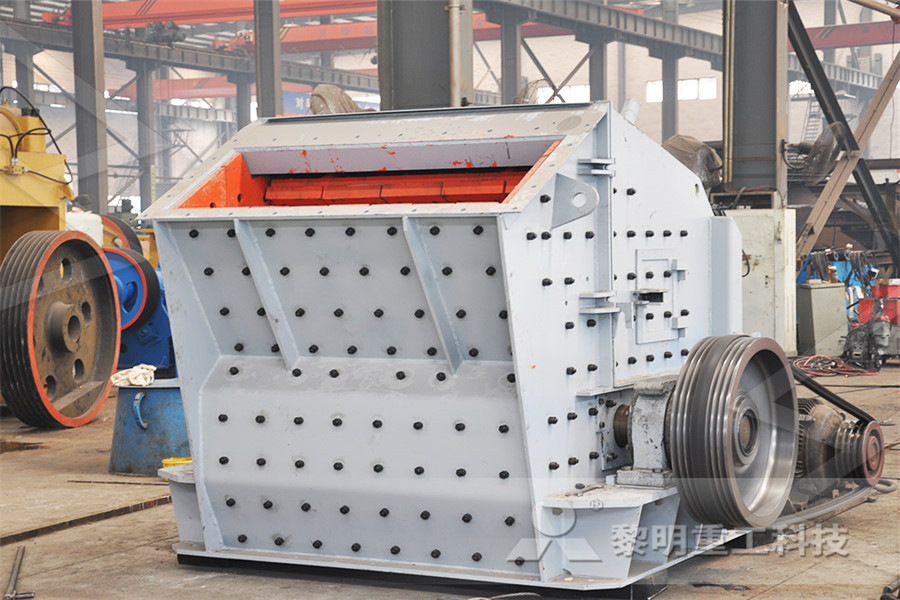

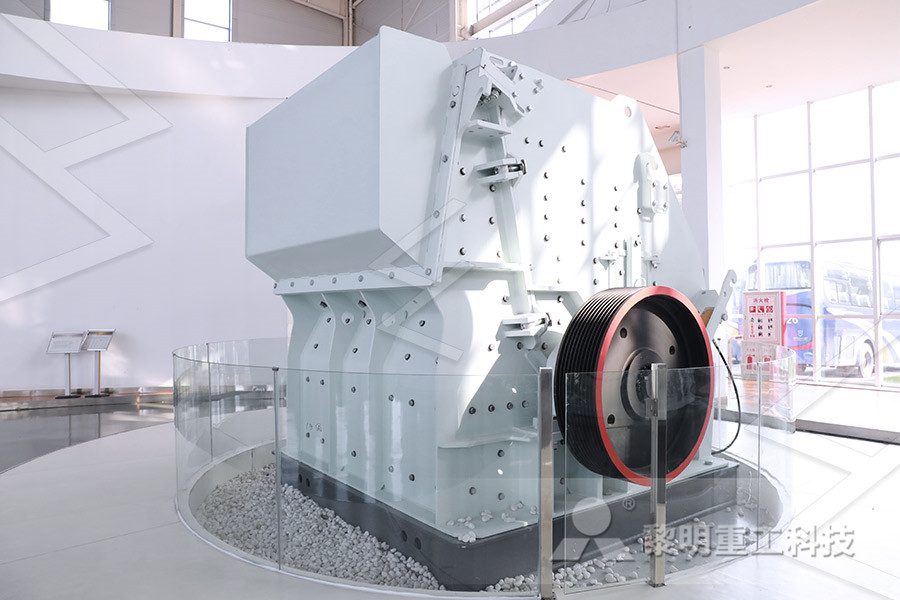

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

recycling of metal slag

2019-11-06T09:11:35+00:00

Slag recycling and reuse – GREENY approach Outotec

Jan 12, 2021 Slag landfills can emit heavy metals to the environment (soil and water) for very long time periods what represents a high environmental impact Instead of storing slag as industrial waste, it is nowadays considered more as a valuable secondary raw materialSlag processing, or also referred to as bottom ash recycling or IBA recycling, and metal recovery on your site are the first steps in the range of services that Recco offers We engineer and manufacture a customized installation for temporary processing built up and installed from modular machinery or install a permanent systemOn site slag recycling Recco Non Ferro MetalsMay 07, 2018 Another type of slag that is produced in considerable quantity (ton/year) by the steelmaking industry is ladle slag Because ladle slag is a premelted flux, when it is recycled in the steelmaking process, it is easy to be remelted This type of slag has good physical properties, high inclusion absorptivity, and high sulfide capacityTreatments and Recycling of Metallurgical Slags IntechOpen

Industrial Solid Waste Recycling [ Slag ] MC

Slag generally comes from factories such as cement plants, thermal power plants, smelters, etc, mainly from the following sources: ① Oxides formed by oxygenation of various impurity elements (such as Si, Mn, P, etc) contained in iron and steel (hot metal, scrap)The present work is aimed at addressing both aspects by employing recycling to generate wealth from copper slag and producing utilizable materials at the same time thus restoring the ecosystem Copper slag was characterized and processedRecovery of metal values from copper slag and reuse of Slag generally comes from factories such as cement plants, thermal power plants, smelters, etc, mainly from the following sources: ① Oxides formed by oxygenation of various impurity elements (such as Si, Mn, P, etc) contained in iron and steel (hot metal, scrap)Industrial Solid Waste Recycling [ Slag ] MC

Recovery of metal values from copper slag and reuse of

The present work is aimed at addressing both aspects by employing recycling to generate wealth from copper slag and producing utilizable materials at the same time thus restoring the ecosystem Copper slag was characterized and processedJul 29, 2016 Slag is a typical byproduct generated during hightemperature metallurgical processes It must be treated appropriately to meet the increasingly strict environmental requirements and to realize the economic benefits1,2 The present topic, “Slag Metallurgy and Metallurgical Waste Recycling,” collects eight articles, which demonstrate the progress of slag metallurgy and metallurgical waste Slag Metallurgy and Metallurgical Waste Recycling High slag viscosity leads to more fine aluminum metal entrapped in the salt slag and thus increases the load of salt slag recycling It was found that viscosity of the salt flux is increased with the amount of entrapped nonmetallic components, which affect the settling of heavier materialsAluminium recycling and environmental issues of salt slag

Slag: From Metals Byproduct to Valuable Construction Material

The concerns with slag recycling are that first, because slag can contain environmentally hazardous materials, it must be analyzed for elemental composition before reuse Second, care must be taken to improve slag potential for other purposes without compromising the quality of the metal is it originally used to produceSteel Slag Recycling by Harsco Metals Minerals Recovering metal from slag is our core business Harsco's operating experience stretches back over 100 years, when we first starting offering a metal recovery service Today, we operate metal recoverySteel Mill Services Steel Slag Recycling by Harsco List of Slag Recycling companies, manufacturers and suppliers (Waste and Recycling) List of Slag Recycling companies, manufacturers and suppliers (Waste and Recycling) due to its properties, the second most used metal after iron Recycling is a major aspect of continued aluminium use, with more than a third of all globally produced Slag Recycling Companies and Suppliers (Waste and

Metal recovery from incinerator slag Panizzolo recycling

Jun 07, 2019 discover more on: https://bitly/2QTbNjIWith Panizzolo refining plant the waste from incinerators are introduced in an EndofWaste recycling cycle which opeJul 11, 2018 The objective of this testing was to classify the recycled slag as an F7 A2EM12 K, which means the testing of the coupon welded with the recycled slag will produce weld metal with an aswelded tensile strength no lower than 70,000 psi (480 MPa) and Charpy Vnotch impact strength of at least 20 ftlb (27 J) at 20°F (29°( ) when produced with an EMl 2K electrode under the conditions Recycling SAW Slag Proves Reliable Repeatable Harbert Slag is the glasslike byproduct left over after a desired metal has been separated (ie, smelted) from its raw oreSlag is usually a mixture of metal oxides and silicon dioxideHowever, slags can contain metal sulfides and elemental metals While slags are generally used to remove waste in metal smelting, they can also serve other purposes, such as assisting in the temperature control of Slag Wikipedia

Seguin Commercial Metals Company

For more than 50 years, CMC Recycling Seguin has provided the greater Seguin area with scrap metal recycling services Beyond Seguin, we serve Guadalupe County and surrounding counties, including Comal, Bexar, Wilson, Gonzales and Karnes Visitors to our recycling In the refinement process, slag forms and floats to the top of the molten metal Slag is the stony waste matter separated from metals during refining The molten metal is then tested and further refined to meet desired quality standards Metal recycling transforms waste into a useful resource, conserves energy, and decreases extraction Metal Recycling, Forever Metal Casting ResourcesAt the same time, for every tonne of endlessly recyclable steel that is made at an integrated steelworks, 600kg of valuable byproducts are also produced for example, 400kg of blast furnace slag is made, which has many different applications, notably to reduce the carbon footprint of cement manufactureByproducts, scrap and the circular economy ArcelorMittal

Borates for Metal Recovery and Recycling US Borax

Aug 13, 2020 Recycling is reprocessing scrap or waste metal into new products Recovery is the process that extracts the purified metal from the scrap Recycling and recovery of metals such as brass, bronze, copper, lead, zinc, and aluminum can come from scrap or from slag that is left over from a primary smelting operationSteel Slag Recycling by Harsco Metals Minerals Recovering metal from slag is our core business Harsco's operating experience stretches back over 100 years, when we first starting offering a metal recovery service Today, we operate metal recoverySteel Mill Services Steel Slag Recycling by Harsco The concerns with slag recycling are that first, because slag can contain environmentally hazardous materials, it must be analyzed for elemental composition before reuse Second, care must be taken to improve slag potential for other purposes without compromising the quality of the metal Slag: From Metals Byproduct to Valuable Construction Material

Recycling and environmental issues of metallurgical slags

to more fine aluminium metal entrapped in the salt slag (may also be seen as a high temperature slurry), and thus increase the load of salt slag recycling Keywords: recyclingList of Slag Recycling companies, manufacturers and suppliers (Waste and Recycling) List of Slag Recycling companies, manufacturers and suppliers (Waste and Recycling) due to its properties, the second most used metal after iron Recycling is a major aspect of continued aluminium use, with more than a third of all globally produced Slag Recycling Companies and Suppliers (Waste and Aug 01, 2018 Steel slag recycling is a serious problem in China The volume of steel slag is growing rapidly because the output of steel is steadily increasing; however, slag’s utilization remains relatively low The utilization rate in China is only 295%, whereas the utilization rate of steel slag in industrial countries is more than 85%Steel slag in China: Treatment, recycling, and management

Advances in slag recycling and reuse UKEssays

3 Recycling of industrial waste and performance of steel slag green concrete LI Yunfeng, YAO Yan, WANG Ling 16, China: Springer, 2009 0768/0773 4 Steel, JFE Reducing Generation and Discharge of Byproducts at JFE Steel 2004 5 Recycling of slag to act as a flux in submerged arc weldingSlag is the glasslike byproduct left over after a desired metal has been separated (ie, smelted) from its raw oreSlag is usually a mixture of metal oxides and silicon dioxideHowever, slags can contain metal sulfides and elemental metals While slags are generally used to remove waste in metal smelting, they can also serve other purposes, such as assisting in the temperature control of Slag WikipediaIn the refinement process, slag forms and floats to the top of the molten metal Slag is the stony waste matter separated from metals during refining The molten metal is then tested and further refined to meet desired quality standards Metal recycling transforms waste into a useful resource, conserves energy, and decreases extraction Metal Recycling, Forever Metal Casting Resources

Byproducts, scrap and the circular economy ArcelorMittal

At the same time, for every tonne of endlessly recyclable steel that is made at an integrated steelworks, 600kg of valuable byproducts are also produced for example, 400kg of blast furnace slag is made, which has many different applications, notably to reduce the carbon footprint of cement manufactureImpurities in the resultan t liquid metal are re moved as slag with th e aid of Generally, recycling of metals saves 75% of energy, 90% raw materials, reduces air pollution by 86%, (PDF) Scrap Iron and Steel Recycling in NigeriaJul 01, 2019 The carbonation of the slag caused the amount of vanadium and chromium leaching to increase, but this heavy metal leaching could merely be suppressed by using the carbonated steel slag as fine aggregate in concrete where the matrix surrounding the slag could act as a sink for any mobile metals (Santos et al, 2012)The recycling and reuse of steelmaking slags — A review

Slag recycling for metal extraction and construction CC

In 2018 and 2019, we therefore invested in new nonferrous metal separators and in “Stratego”, the most efficient metal finishing machinery on the market Below is a brief overview of how we process slag to extract metals:For more than 50 years, CMC Recycling Seguin has provided the greater Seguin area with scrap metal recycling services Beyond Seguin, we serve Guadalupe County and surrounding counties, including Comal, Bexar, Wilson, Gonzales and Karnes Visitors to our recycling Seguin Commercial Metals CompanyRegenerator slag that is recycled to the DeP furnace, on the mass of slag generated in each unit process; the phosphorous distribution between metal and slag; process heat requirements and the What is the importance of slag composition in recycling of