عنا

مرحبا هل يمكنني مساعدتك؟

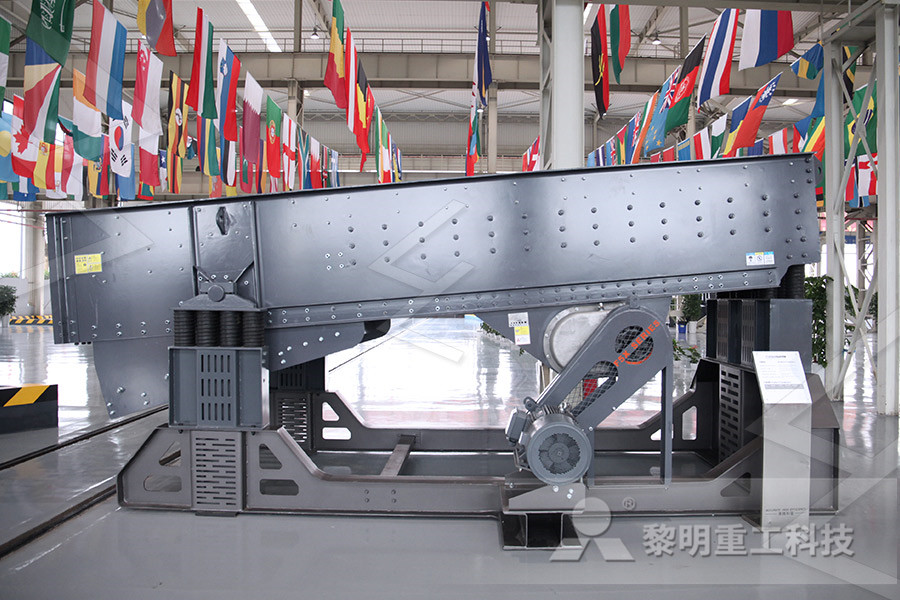

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

carbon in pulp technology for the extraction of gold pdf

2020-09-19T12:09:40+00:00

The process design of gold leaching and carboninpulp

The carbon in the reactor into which pregnant pulp is fed (referred to as the first reactor) becomes highly loaded with gold Loaded carbon values on operating plants range from 300 to 20 000 grams of gold per ton of carbon, a concentrating factor of about 1 000–1 500 A portion of the loaded carbon is periodically removed from the first gold extraction after leaching by cyanide in aerated alkaline slurries The continuous processes of gold recovery by adsorption on activated carbon in agitated tanks, namely the carboninpulp (CIP) and the carboninleach (CIL) processes, have been widely used since the 1970s Due to the economic importance of these processes, their simulation hasDYNAMIC SIMULATION OF THE CARBONIN PULP AND CarboninPulp (CIP) and CarboninLeach (CIL) processes have surface areas of about 1000 m²/g ie one gram of activated carbon (the amount of which will occupy the same space as the end of a person's thumb) has the same surface area as two football fields The high surface area is contained in the millions of pores of varying sizes, these beingACTIVATED CARBON IN GOLD RECOVERY Kemix

(PDF) Gold CIP and CIL process optimization in a capital

The carbon in pulp (CIP) and carbon in leach (CIL) processes became firmly established in the gold mining industry in the 1980s, initially in South Africa and Australia, from where they spread cyanide leach carboninpulp adsorption circuit The residual gold content of the bleed stream can also be recovered in a separate precipitation step Treating a feed material with a high gold content minimises the proportion of the raffinate which must be bled to control impurities The longterm stability of the organic phase was closelyGold refining by solvent extraction—the Minataur™ ProcessThe carboninpulp (CIP) process is now well established in the South African gold industry, with a total of over 1 million metric tons of material being treated each month in six large plants This tonnage is derived from ground ore, from filtered pulp, from calcine, and from reclaimed sandtailings dumpsCarboninpulp processes in South Africa ScienceDirect

Carboninpulp processes in South Africa ScienceDirect

Dec 01, 1984 Hydrometallurgy, 13 (1984) 169192 169 Elsevier Science Publishers BV, Amsterdam Printed in The Netherlands CARBONINPULP PROCESSES IN SOUTH AFRICA* PETER A LAXEN Council for Mineral Technology, Private Bag X3015, Randburg, 2125 (South Africa) (Received September 7, 1983; accepted in revised form June 2~1, 1984) ABSTRACT Laxen, PA, 1984Oct 26, 2012 The feasibility of a process involving the use of activated carbon in a multistage column (NIMCIX contactor) for the recovery of gold from unclarified pregnant solutions was investigated on pilotplant scale It was found that satisfactory extractions, corresponding to a recovery of 996 percent, can be achieved with an average gold concentration of 00077 ppm in the barren solutions from a Au Recovery Using an Activated Carbon Column SpringerLink12 The Carboninpulp Process Process Chemistry and Unknown Areas 3 a; Leaching of Gold from the Ore 3 b) Adsorption of Aurocyanide onto Activated Carbon l c) Carbon Acid Washing and Elution 7 d) Gold Electrot'inning or Precipitation 8 e) Carbon Reactivation 8 f) Other Features of the CIP Process 9THE CHEMISTRY OF THE CARBONINPULP PROCESS

(PDF) Gold Extraction and Recovery Processes For Internal

Gold Recovery from Solution The common processes for recovery of the solubilized gold from solution are (certain processes may be precluded from use by technical factors) [5,6]: Carbon Adsorption MerrillCrowe process Electrowinning Ionexchange/Solvent Extraction (i) Carbon Adsorption The process known as carbon in pulp, or charcoal in pulp or Gold Recovery Via Activated Carbon from Cyanide Liquors Containing Cuprous Cyanocomplexes Activated carbon is widely used for gold recovery from cyanide leach liquors via carboninleach (CIL) or carboninpulp (CIP) technology From all the base metals cyanide complexes typicallyTECHNICAL PAPER Purolitetreated with cyanide, the rock dissolves into solution and is eventually recovered using activated carbon which binds with gold molecular particles The Merril Crowe system is still widely used today Carboninpulp (CIP) is an extraction technique for recovery of gold Hallgarten

Processing technologies for goldtelluride ores

solidated Gold Mines Pty Ltd (KCGM) is to produce a sulfidetelluride concentrate that is fluidbed roasted The resulting calcine is leached with cyanide and the gold is recovered by the carboninpulp (CIP) process [7] A few chemical oxidative pretreatments have been investigated to improve gold recoveries, including bromocyanidation,gold recovery while meeting their fiscal and environmental responsibilities The Carbon Company THE GOLD EXTRACTION industry faces perennial challenges even in times when gold prices are high Mines must strive to process ore of diminishing quality, yet control operating costs at a level that maximizes the return on investmentActivated Carbon forGold Recovery Jacobi CarbonsA process for adsorbing gold from a leach pulp by means of activated carbon is described in which the leach pulp (the leach solution together with the subdivided gold bearing ore) is diluted to a specific gravity of less than that of the activated carbon and is subsequently passed upwardly through a multistage liquid/solid contacting columnUSA Recovery of gold by a carboninpulp process

Dynamic simulation of the carboninpulp and carbonin

Carboninleach and carboninpulp are continuous processes that use activated carbon in a cascade of large agitated tanks, which have been widely used to recover or concentrate precious metals in gold extraction plants In the carboninpulp process adsorption occurs after the leaching cascade section of the plant, and in the carboninleach Oct 26, 2012 The feasibility of a process involving the use of activated carbon in a multistage column (NIMCIX contactor) for the recovery of gold from unclarified pregnant solutions was investigated on pilotplant scale It was found that satisfactory extractions, corresponding to a recovery of 996 percent, can be achieved with an average gold concentration of 00077 ppm in the barren solutions from a Au Recovery Using an Activated Carbon Column SpringerLinkThe dissolved gold in solution is adsorbed onto activated carbon When the carbon is loaded with enough gold it is removed from the circuit and sent to elution where the adsorption process is reversed and the gold is stripped off the carbon back into solution, electrowon and smelted into barsLeaching Adsorption Resource Book

TREATMENT OF CYANIDE HEAP LEACHES AND TAILINGS

22 Tank Operations (CarboninPulp and CarboninLeach) In CarboninPulp and CarboninLeach cyanidation methods, primary leaching takes place in a series of tanks Finely ground gold ore is slurried with the leaching solution The resulting goldcyanide complex is then adsorbed on activated carbon15 Gold extraction processes 4 Carbon in pulp process 25 Complexing of gold by thiocompounds 26 a straightforward recovery by a relatively simple conventional technology Refractory gold ores, however, require rather sophisticated recovery techniques Different ways of goldsketches tables UNIGEcyanide leach carboninpulp adsorption circuit The residual gold content of the bleed stream can also be recovered in a separate precipitation step Treating a feed material with a high gold content minimises the proportion of the raffinate which must be bled to control impurities The longterm stability of the organic phase was closelyGold refining by solvent extraction—the Minataur™ Process

v118n5a2 Test work to examine the potential for improving

The Navachab Gold Mine is an openpit gold operation located in Namibia The metallurgical flow sheet consists of crushing, milling, leaching by CIP (carbon in pulp), and electrowinning Extraction in the leach section is approximately 67%, increases to approximately 86% by the end of carbon12 The Carboninpulp Process Process Chemistry and Unknown Areas 3 a; Leaching of Gold from the Ore 3 b) Adsorption of Aurocyanide onto Activated Carbon l c) Carbon Acid Washing and Elution 7 d) Gold Electrot'inning or Precipitation 8 e) Carbon Reactivation 8 f) Other Features of the CIP Process 9THE CHEMISTRY OF THE CARBONINPULP PROCESS recover the dissolved gold, such as cementation, adsorption onto activated carbon (carboninpulp and carboninleach) or onto a resin (resininpulp and resininleach), ionexchange chromatography, and solvent extraction4 Solvent extraction is an effective method for the separation and purification of Solvent Extraction of Gold(III) with Diethyl Carbonate

Hallgarten

treated with cyanide, the rock dissolves into solution and is eventually recovered using activated carbon which binds with gold molecular particles The Merril Crowe system is still widely used today Carboninpulp (CIP) is an extraction technique for recovery of gold cyanide leach carboninpulp adsorption circuit The residual gold content of the bleed stream can also be recovered in a separate precipitation step Treating a feed material with a high gold content minimises the proportion of the raffinate which must be bled to control impurities The longterm stability of the organic phase was closelyGold refining by solvent extraction—the Minataur™ ProcessCarboninleach and carboninpulp are continuous processes that use activated carbon in a cascade of large agitated tanks, which have been widely used to recover or concentrate precious metals in gold extraction plants In the carboninpulp process adsorption occurs after the leaching cascade section of the plant, and in the carboninleach Dynamic simulation of the carboninpulp and carbonin

Activated Carbon forGold Recovery Jacobi Carbons

gold recovery while meeting their fiscal and environmental responsibilities The Carbon Company THE GOLD EXTRACTION industry faces perennial challenges even in times when gold prices are high Mines must strive to process ore of diminishing quality, yet control operating costs at a level that maximizes the return on investmentA process for adsorbing gold from a leach pulp by means of activated carbon is described in which the leach pulp (the leach solution together with the subdivided gold bearing ore) is diluted to a specific gravity of less than that of the activated carbon and is subsequently passed upwardly through a multistage liquid/solid contacting columnUSA Recovery of gold by a carboninpulp process The Navachab Gold Mine is an openpit gold operation located in Namibia The metallurgical flow sheet consists of crushing, milling, leaching by CIP (carbon in pulp), and electrowinning Extraction in the leach section is approximately 67%, increases to approximately 86% by the end of carbonv118n5a2 Test work to examine the potential for improving

Extracting Gold By Carbon In Pulp

Two main methods Carbon In Pulp (CIP) and Carbon Columns may consist of the most widely used technique for extracting gold today Both methods use a large tank in the column parallel step where gold is dissolved in the slurry ( pulp) through a chemical process and combine agitation , Gold process flow sheet development and test work has always been part of MINTEK’s technology service whilst MINTEK played a prominent role in establishing the CarbonInLeach (CIL) and CarbonInPulp (CIP) cyanidation technology, during the 1970’s to 1980’s international gold boomGold Group MINTEK MINTEKGriffin, A F (1982) "Carbon Desorption Process Development at Micron Research (Western Australia)," in Seminar on CarboninPulp Technology for the Extraction of Gold Perth, WA:Desorption of gold and silver from activated carbon

[PDF] Dynamic simulation of the carboninpulp and carbon

Carboninleach and carboninpulp are continuous processes that use activated carbon in a cascade of large agitated tanks, which have been widely used to recover or concentrate precious metals in gold extraction plants In the carboninpulp process adsorption occurs after the leaching cascade section of the plant, and in the carboninleach process leaching and adsorption occur simultaneouslyCarbonlnPulp Technology for the Extraction of Gold, Perth and Kalgoorlie, (Reprinted 1988) $ 2200 A Study of the ElectroKinetic Properties of Activated Carbon Used as a Tool for Gold ExtractionCarbonlnPulp Technology for the Extraction of Gold the activated carbon product The characteristics of the activated carbon product are thus dependent on raw material A hard dense raw material results in a hard dense activated carbon with a micropore favouring structure A soft, less dense raw material results in a soft light activated carbon with an open pore structure 18ACTIVATED CARBON IN GOLD RECOVERY Kemix