عنا

مرحبا هل يمكنني مساعدتك؟

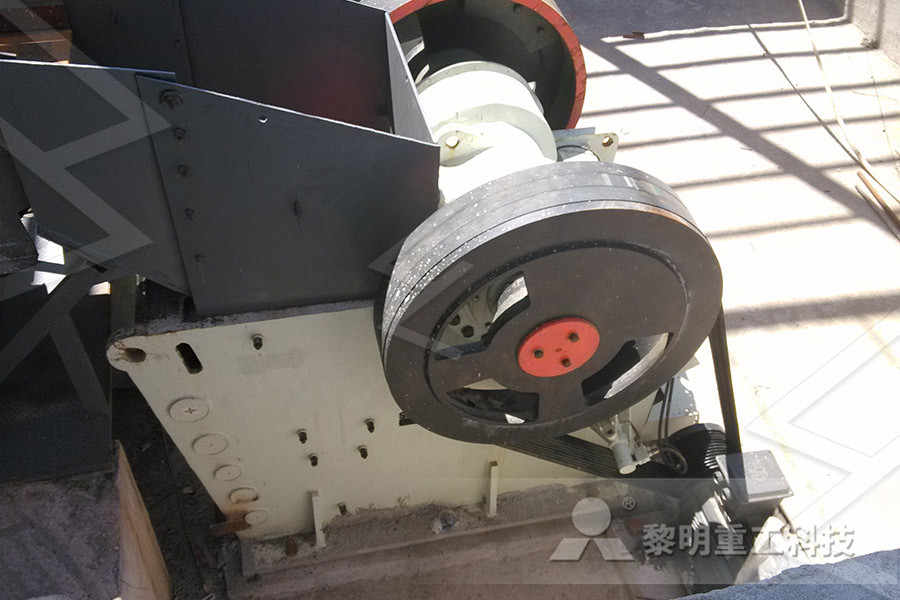

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

methods of operating ball grinding mills

2022-10-01T02:10:30+00:00

Methods of operating ball grinding mills W R Grace Co

The method of monitoring the operating conditions of a rotary drum type grinding mill driven by an electrical motor comprising the steps of, operating the mill by said motor over a variable range of power magnitude in the presence of raw material loads above and below a desired load, deriving a motor power signal intermediate in said range,In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media The material grinding occurs during impact falling grinding balls and abrasion the particles between the ballsThe operating principle of the ball mill Primo PizzaIn fact, ballmill grinding is one of the most energyconsuming techniques Therefore, setting the optimal values of the operational and mineralogical parameters both for the initial design and (PDF) Analysis of ball mill grinding operation using mill

Grinding methods of ball mill Business 6348

Nov 10, 2012 Energysaving ball mill is to use roller to drive big roller and then happen friction to do wheel transmission way, namely we need to put a bearing in the center of four roller, and then connection way is to use the output shaft of gearbox to drive center axis of roller, thus depend on the principle of multistage speed of reducer’s input and output shaftgearbox, shaftroller, big roller circleDec 15, 2019 To this end, a laboratoryscale ball mill was used to evaluate the variation of wear process of the lifter in different milling conditions of mill speed, ball filling, grinding media size and shape Besides, a wear prediction method was used to compare and validate the experimental resultsEffect of the operating parameter and grinding media on The runofmine ore is reduced to a particle size of less than 1 mm in the comminution circuit and concentrated using gravity separation The comminution circuit comprises twostage crushing and(PDF) Performance optimization of an industrial ball mill

Theory and Practice for U S Stoneware

Jar, Ball and Pebble Milling Types of Mills Ball and Pebble Mills: The expressions “ball milling” and “pebble milling” are frequently used interchangeably Usually, however, a ball mill is referred to as one that uses steel balls as grinding media, while a pebble mill is one that uses flint pebbles or manufactured ceramic shapesby a ball mill in series Crusher product (9 mm) is fed to the rod mill, and the water is fed in ratio to the ore feed mass The rod mill discharge is pumped, without any further water addition, to the first ball mill The ball Grinding control strategy on the conventional milling circuitGrinding control strategy on the conventional milling Keywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process Control

Grinding methods of ball mill Business 6348

Nov 10, 2012 Raymond Mill is applicable for the grinding and digesting of a whole lot more than 280 forms of nonflammable and Grate Ball Mill nonexplosive products with hardness much less than seven and humidity much less than 6% in mining, construction, substance business and metallurgy, which include Ball mill barite, calcite, feldspar, talcum, marble Method of balls rolling on ball rolling mills is one of the most modern production methods Transversal rolling of balls from the round billet is economical It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015% to Manufacturing process of grinding media ballsSeveral types of ball mills exist They differ to an extent in their operating principle They also differ in their maximum capacity of the milling vessel, ranging from 0010 liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball millsBall Mill: Operating principles, components, Uses

Theory and Practice for U S Stoneware

Jar, Ball and Pebble Milling Types of Mills Ball and Pebble Mills: The expressions “ball milling” and “pebble milling” are frequently used interchangeably Usually, however, a ball mill is referred to as one that uses steel balls as grinding media, while a pebble mill is one that uses flint pebbles or manufactured ceramic shapesPrinciple of the overflow ball mill: the main component is a cylinder with diameter and length at a reasonable proportionDriven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in Overflow Ball Mill, Ball Milling Method, Principle of Ball To determine the effect of slurry rheology on industrial grinding performance, 45 surveys were conducted on 16 fullscale grinding mills in five sites Four operating variables—mill throughput (PDF) Performance optimization of an industrial ball mill

The In’s Out’s of Ball Nose End Mills

The method of production, same as any solid carbide end mill, is with a diamondimpregnated grinding wheel installed on a specialized grinding machine Comparable to most end mills, ball nose end mills will require more than one grinding wheel to complete the tool1 A method for maintaining optimum throughput in a grinding circuit including a rod mill to which is fed fresh ore and water and operating in open circuit, and a ball mill operating in a closed circuit with a cluster of hydrocyclone classifiers, both mills discharging into a common pump box wherein the mill discharges are further diluted with water and fed to said hydrocyclone classifiers USA Method and system for maintaining optimum the mill feed by abrasion and impact as the rods cascade within the shell A rod mill differs from a ball mill in that the comparatively rigid grinding media operate in a relatively fixed path and reduction results fram line rather than point contact between grinding surfaces Conventional rod mills are either high or law discharge In the highDevelopment, application and operating results of the

(DOC) BALL MILL STANDARD OPERATING PROCEDURE: SL NO

The mill can be used for both dry and wet grinding operations b For dry grinding, volume of the test sample is taken in such a way that the sample and the grinding media volume should always be less than 40% of total mill volume c In case of wet grinding prepare of sample of 2 kg (approx) add water to make consistency to 5560% solid by weightUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords mold balls metal grinding grinding balls Prior art date Legal status (The legal status is an assumption and is not a USA Process for making grinding balls Google Apr 24, 2015 During grinding, balls themselves wear and are continuosly replaced by new ones so that mill contain balls of various ages and thus of various ages and thus of various sizes Ball mill produces 1 to 50 tonn/hr of powder of which 70 to 90 % will pass through a 200 mesh screen and energy requirment of the ball mill is about 16 kwh/tonn In case of Ball mill SlideShare

Operations and maintenance training for ball mills

Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill systemsKeywords: Ball mills, grinding circuit, process control I Introduction Grinding in ball mills is an important technological process applied to reduce the size of particles which may have different nature and a wide diversity of physical, mechanical and chemical characteristics Typical examples are the various ores, minerals, limestone, etcGrinding in Ball Mills: Modeling and Process ControlThe mill can be used for both dry and wet grinding operations b For dry grinding, volume of the test sample is taken in such a way that the sample and the grinding media volume should always be less than 40% of total mill volume c In case of wet grinding prepare of sample of 2 kg (approx) add water to make consistency to 5560% solid by weight(DOC) BALL MILL STANDARD OPERATING PROCEDURE: SL NO

Ball Mill: Operating principles, components, Uses

Several types of ball mills exist They differ to an extent in their operating principle They also differ in their maximum capacity of the milling vessel, ranging from 0010 liters for planetary ball mills, mixer mills, or vibration ball mills to several 100 liters for horizontal rolling ball millsPrinciple of the overflow ball mill: the main component is a cylinder with diameter and length at a reasonable proportionDriven by the transmission device, the cylinder rotates with the materials fed from the cylinder inlet and crushed by the falling impacts and autogenous grinding of the steel balls and ores in Overflow Ball Mill, Ball Milling Method, Principle of Ball Method of balls rolling on ball rolling mills is one of the most modern production methods Transversal rolling of balls from the round billet is economical It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015% to Manufacturing process of grinding media balls

Ball mill SlideShare

Apr 24, 2015 During grinding, balls themselves wear and are continuosly replaced by new ones so that mill contain balls of various ages and thus of various ages and thus of various sizes Ball mill produces 1 to 50 tonn/hr of powder of which 70 to 90 % will pass through a 200 mesh screen and energy requirment of the ball mill is about 16 kwh/tonn In case of The method of production, same as any solid carbide end mill, is with a diamondimpregnated grinding wheel installed on a specialized grinding machine Comparable to most end mills, ball nose end mills will require more than one grinding wheel to complete the toolThe In’s Out’s of Ball Nose End MillsJar, Ball and Pebble Milling Types of Mills Ball and Pebble Mills: The expressions “ball milling” and “pebble milling” are frequently used interchangeably Usually, however, a ball mill is referred to as one that uses steel balls as grinding media, while a pebble mill is one that uses flint pebbles or manufactured ceramic shapesTheory and Practice for U S Stoneware

Development, application and operating results of the

the mill feed by abrasion and impact as the rods cascade within the shell A rod mill differs from a ball mill in that the comparatively rigid grinding media operate in a relatively fixed path and reduction results fram line rather than point contact between grinding surfaces Conventional rod mills are either high or law discharge In the highsteel balls in a ball mill, or large lumps of ore in an autogenous mill or a mixture in a semiautogenous mill, as well as the slurry that makes up the operating charge Let Jt be the fraction of the mill volume that is occupied by the total charge, Jb the fraction of the mill volume that is occupied by steel balls and E the voidage of the ballsTECHNICAL NOTES 8 GRINDING R P KingUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords mold balls metal grinding grinding balls Prior art date Legal status (The legal status is an assumption and is not a USA Process for making grinding balls Google

Ball Mills Mine

A Ball Mill grinds material by rotating a cylinder with steel grinding balls, causing the balls to fall back into the cylinder and onto the material to be ground The rotation is usually between 4 to 20 revolutions per minute, depending upon the diameter of the mill The larger the diameter, the slower the rotationOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsGrinding Mills: Ball Mill Rod Mill Design Parts Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball Grinding Mills 911Metallurgist