عنا

مرحبا هل يمكنني مساعدتك؟

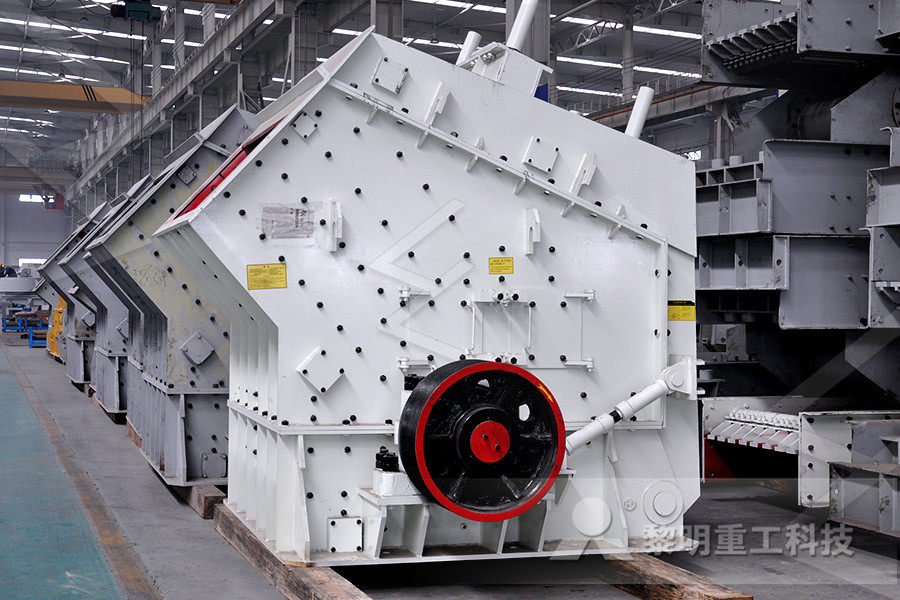

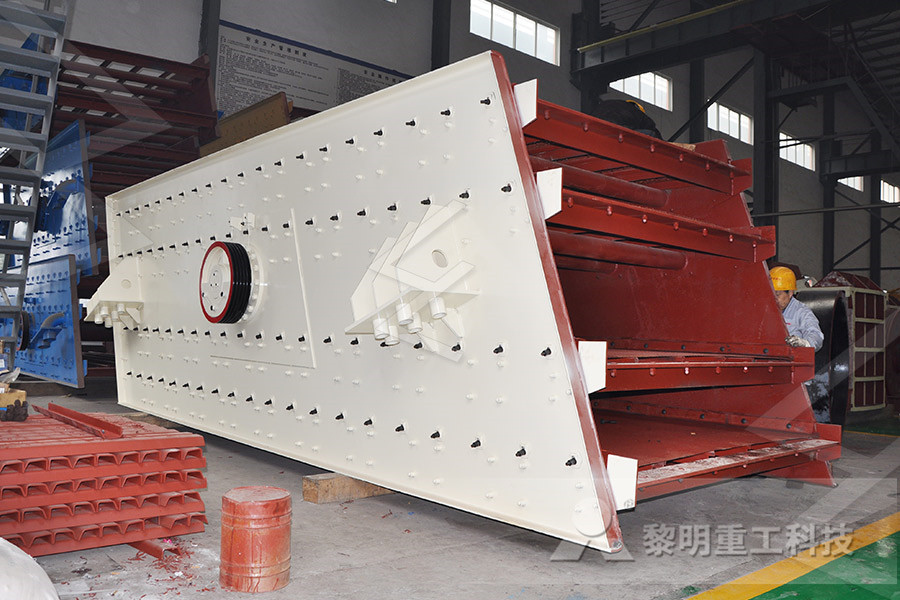

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

grinding process for manufacturing.html

2019-05-19T20:05:14+00:00

Manufacturing Process Of Grinding Machine

Grinding Machine Gtu Manufacturing Process Nov 26 2014 Grinding Machine GTU Manufacturing Process 1 Company Logo Grinding machines artechbyhp blogspot com 2 Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 0 25 to 0 50 mm Tool used is a abrasive wheelMay 29 2018 Grinding Soft Grinding: Similar to deflashing, except that a grinding stone is used to improve precision Heattreating: Carbon steel balls are next carburized and hardened Heat treatment imparts the desired hardness and case depth Descaling: This step removes the residues and byproducts from the heattreating processThe Manufacturing process for balls, stainless steel balls Grinding A diamond disk is used for grinding due to the hardness of the hard metal products can reach hardness of 2000 HV Grinding with diamond wheel takes time and is quite expensive because the thickness of removable chip is around 0001 mm only (Some material hardness: diamond 7500 HV, quartz 1100 HV and highspeed steel around 800 HV)Manufacturing KovametalliIN

Manufacturing

The process of hardening is carried out in two phases: heating of glass to the softening temperature is followed by rapid cooling The pretreatment of glass (cutting, grinding, drilling) must be performed before the hardening procedureGrinding The grinding process undergoes four stages namely: Face Grinding: In the face grinding process, duplex machine is used Components are checked for size variations, flatness, roughness, parallelism and burning OD Grinding: In this stage material is checked for 2 point ovality, 3 point ovality, roundness and roughnessMarc Bearing Manufacturer and exporter of Tapered Roller Chipping Grinding Equipment Manufacturing in the US industry statistics This percentage represents tangible assets held for sale in the ordinary course of business, or goods in the process of production for such sale, or materials to be consumed in the production of goods and services for sale Chipping Grinding Equipment Manufacturing in the US

The Manufacturing process for balls, stainless steel balls

Soft Grinding: Similar to deflashing, except that a grinding stone is used to improve precision Heattreating: Carbon steel balls are next carburized and hardened Heat treatment imparts the desired hardness and case depth Descaling: This step removes the residues and byproducts from the heattreating processGrinding A diamond disk is used for grinding due to the hardness of the hard metal products can reach hardness of 2000 HV Grinding with diamond wheel takes time and is quite expensive because the thickness of removable chip is around 0001 mm only (Some material hardness: diamond 7500 HV, quartz 1100 HV and highspeed steel around 800 HV)Manufacturing KovametalliINMar 15, 2021 The dry process although cheaper needs excessive fine grinding It is more suited for the hard material (Fig 31) The wet process, on the other hand, is free from the dust, grinding is easier and the composition of the cement can easily be controlledExplain dry and wet process of cement manufacturing

Inventions Free FullText OpenSource Grinding Machine

Future work is needed to make this process less time consuming Compression screws could be manufactured using a mill with a fourth axis, or a lathe Industrial extrusion screws are manufactured using a cylindrical grinding machine The machine developed in this work is classified as an outside diameter cylindrical grinding machine Chipping Grinding Equipment Manufacturing in the US industry statistics This percentage represents tangible assets held for sale in the ordinary course of business, or goods in the process of production for such sale, or materials to be consumed in the production of goods and services for sale Chipping Grinding Equipment Manufacturing in the US The process of spring grinding is accomplished by an spring grinder The spring grinder has two (2) horizontal grinding wheels than are spaced apart to permit the length of the spring to enter between both grinding wheels Then the spring dish is a separate plate Springs Manufacturing Acxess Spring

Tool Services Custom Standard Cutting Grinding

Grinding; Manufacturing Services TMA Tool Services can also manufacture most any type of standard or custom roundshank tools for the metalworking industry These tools include drills, step drills, endmills, reamers, step reamers, and many others in all types of configurations including thrucoolant, special features, coatings, etc milling, lathe and water jet machining, grinding, thread rolling and forming Our Working Process Harlow Aerostructures LLC, located in Wichita, Kansas, has been supplying to the aerospace industry since 1954 Machining Machining High Speed Cellular manufacturingManufacturingManufacturing Sudhir Fasteners houses cold forming capabilities for products ranging from 3mm to 14 mm in cross section Cold forming is a high speed forging process where coiled wire at room temperature is precisely sheared to length, and then moved through a succession of tool and die cavities to displace the working metal, either larger/smaller in diameter, longer/shorter in length, or to Manufacturing SudhirFasteners

Precision Manufacturing David A Dornfeld, DaeEun Lee

Today there is a high demand for highprecision products The manufacturing processes are now highly sophisticated and derive from a specialized genre called precision engineering Precision Manufacturing provides an introduction to precision engineering and manufacturing with an emphasis on the design and performance of precision machines and machine tools, metrology, tooling elements Considering the internal grinding process as shown in Figure 24a in which the spindle is out of balance, the resulted unbalance force is assumed in a harmonic form, Fsin( ωt+ϕ) This force will vibrate the grinder relative to the workpiece and result in forced vibrations Again, an undamped massspring system under harmonic forces is Machining Dynamics: Fundamentals, Applications and China Grinding Wheel Manufacturing, China Grinding Wheel Manufacturing Suppliers and Manufacturers Directory Source a Large Selection of Grinding Wheel Manufacturing Products at grinding wheel,peanut butter grinding wheel,cylindrical grinding wheel from China AlibabaChina Grinding Wheel Manufacturing, China Grinding Wheel

Springs Manufacturing Quality Spring, Affordable Prices

The process of spring grinding is accomplished by an spring grinder The spring grinder has two (2) horizontal grinding wheels than are spaced apart to permit the length of the spring to enter between both grinding wheels Then the spring dish is a separate plate Prior to grinding, a number of stages are involved in gear manufacturing: Hobbing is a roughing operation which produces a gear profile with stock remaining for a final grinding process (see figure 1) Hardening/HeatTreating is a group of processes used to alter the physical, and sometimes chemical, properties of a materialGear Manufacturing Diamond Grinding Wheel/Diamond Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fedGRINDING PROCESS

The Importance of Material Grinding in Manufacturing

Grinding Process The grinding wheel consists of several abrasive particles which act as minute cutting edges, and these particles are bonded with the help of bonding material The advantage of using such a process over conventional metal removal processes are as follows The rate of removal of material is much higher than, say, a traditional fileNov 15, 2016 Manufacturing process of grinding is used to better the quality of the surface of the material Normally is used as a finishing process in the end of the manManufacturing Processes Grinding Process YouTubeApr 21, 2009 DIN norm 8589 subsumes within the group “machining with geometrically defined cutting edges” the following material removal manufacturing processes: grinding, honing, lapping, free abrasive grinding and abrasive blast cutting chining is carried out in these production methods by means of more or less regularly formed grains composed Manufacturing Processes 2: Grinding, Honing, Lapping

APPLICATIONS AND ADVANTAGES OF GRINDING PROCESS

Cylindrical grinding process is used for grinding the outer surface of cylindrical object; Centerless grinding process is used for preparing the transmission bushing, shouldered pins and ceramic shafts for circulator pumps Internal grinding process is used for finishing the During the grinding stage, the fine stones from the raw material warehouse are placed in a precipitated calcium powder mill for grinding, and the powder is sent to a superclassified machine Fineness can be adjusted between 2002000 mesh The manufacturing process of precipitated calcium carbonate can be divided into the following 8 steps: 1Precipitated calcium carbonate manufacturing processGrinding A diamond disk is used for grinding due to the hardness of the hard metal products can reach hardness of 2000 HV Grinding with diamond wheel takes time and is quite expensive because the thickness of removable chip is around 0001 mm only (Some material hardness: diamond 7500 HV, quartz 1100 HV and highspeed steel around 800 HV)Manufacturing KovametalliIN

Manufacturing

The process of hardening is carried out in two phases: heating of glass to the softening temperature is followed by rapid cooling The pretreatment of glass (cutting, grinding, drilling) must be performed before the hardening procedureOct 24, 2018 Calculating wheel life is essential for forecasting wheel usage and the abrasive costs associated with a grinding process In order to calculate the wheel life, it is essential to know which dressing methodology is being used There are two types of dressing methods that can be used in a creepfeed grinding process: 1How to Calculate Wheel Life in a CreepFeed Grinding ProcessOne can easily imagine that grinding radii and surfaces using a combination machining process faces its own problems For instance, grinding the radii requires a number of passes, as the shaft can only take a certain amount of pressure before it “bends;” whereas the pressure exerted when grinding the surfaces is not an issue, as it works in A Boost for Crankshaft Manufacturing EMAG Group

Cylindrical Grinding Process to Benefit Manufacturing Process

Oct 23, 2020 The cylindrical grinding process is a manufacturing technique that shapes the exterior of objects by rotating them around a central axis This is done using cylindrical grinders, which rotate and shape objects using an abrasive wheel The wheels themselves vary in size, material, and configuration depending on the application, which means these systems can be adapted to suit a wide range of Union Process is the source for the most uptodate information on grinding balls and other media Download our Grinding Media Literature (PDF) to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of mediaGrinding Media Union ProcessFor example, if a polishing process is needed for the removal of grinding damage after wafer thinning, multipleprocessing equipment capable of grinding using a grinding wheel and dry polishing lowers the risk of waferlevel breakage during wafer transfer It is also effective for reducing that risks of always supporting the wafer with tapes by Dicing and Grinding Using the Conventional Process (TGM

Medical Guidewires: Assembly and Manufacturing TE

TE has extensive core grinding capabilities with stateoftheart precision grinding equipment featuring computeraided manufacturing (CAM) technology and a profilometer grind profile measurement system to ensure we meet customers’ tight tolerance precision grinding requirementsOur guidewires are used in the most challenging coronary, peripheral and neurovascular applications, and our