عنا

مرحبا هل يمكنني مساعدتك؟

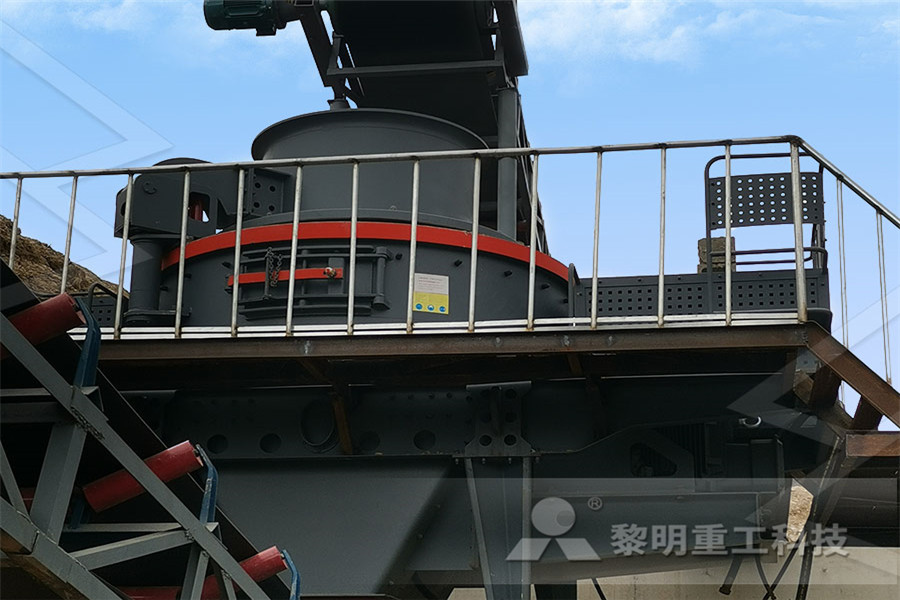

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

pper extraction process flow

2021-10-22T04:10:08+00:00

Copper Mining Extraction Process Flow Chart

This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore) Having a quick look now at how porphyry ores are treated and the metals extracted There are two main Copper Mining and Extraction: Oxide Ores The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refiningFlow diagram copper extraction process Manufacturer Of Copper Mining Extraction Process Flow Chart This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral (ore)Copper Mining Extraction Process Flow Chart Process

The Extraction of Copper Chemistry LibreTexts

Aug 21, 2020 Copper can be extracted from nonsulfide ores by a different process involving three separate stages: Reaction of the ore (over quite a long time and on a huge scale) with a dilute acid such as dilute sulfuric acid to produce a very dilute copper (II) sulfate solution Concentration of the copper (II) sulfate solution by solvent extractionFig 1 General flow diagram of the copper solvent extraction process The copper transfer between the aqueous and organic phases takes place in mixers and the phases are separated in settlers The equipment used for the solvent extraction process varies considerably For example, in Outokumpu VSF technology the organicAN INDUSTRIAL COPPER SOLVENT EXTRACTION PROCESSA simplified schematic drawing of copper flotation flowsheet Runofmine open pit ore will be crushed in a gyratory crusher The crushed ore will be processed by means of semiautogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate The concentrate will be trucked via the existing road network in the area to a Copper Process Flowsheet Example

AN INTRODUCTION TO COPPER EXTRACTION

The copper extraction process begins at an open cut mine where Copper Ore is blasted and removed via Excavators and Tip Trucks The ore is fed to a Crusher where it is broken down to a specified maximum size and passed through to a conveyorCopper can be extracted from nonsulphide ores by a different process involving three separate stages: Reaction of the ore (over quite a long time and on a huge scale) with a dilute acid such as dilute sulphuric acid to produce a very dilute copper (II) sulphate solution Concentration of the copper (II) sulphate solution by solvent extractioncopper extraction and purification chemguide4 Load flow study and LV cable selection This section is intended to provide a brief introduction to the copper extraction process and the Kinsevere project Additionally information is presented to provide a basic overview of the electrical connection scheme employedAN INTRODUCTION TO COPPER EXTRACTION

AN INDUSTRIAL COPPER SOLVENT EXTRACTION PROCESS

Fig 1 General flow diagram of the copper solvent extraction process The copper transfer between the aqueous and organic phases takes place in mixers and the phases are separated in settlers The equipment used for the solvent extraction process varies considerably For example, in Outokumpu VSF technology the organicCopper can be extracted from nonsulphide ores by a different process involving three separate stages: Reaction of the ore (over quite a long time and on a huge scale) with a dilute acid such as dilute sulphuric acid to Concentration of the copper (II) sulphate solution by solvent extraction The copper extraction and purification chemguideJul 04, 2013 FLOWSHEET DEVELOPMENT IN THE CONTEXT OF COPPER EXTRACTION sargonau Each process unit must pay its way High level costs can be obtained by the O’Hara method eg for a lowgrade copper ore the process capital cost in 1992 dollars is US$ 13,700 T06 includes flotation, thickening and filtration Cost Estimation Handbook for the Flowsheet development in the context of copper extraction

Flow diagram copper extraction process Manufacturer Of

Copper Mining and Extraction: Oxide Ores The process used to treat sulfide copper ores begins at the mine site, where the copperbearing minerals are physically separated from the rest of the rock The flow diagram below shows how the percentage of copper increases as the ore is refined, first physically by froth flotation, then chemically by smelting and finally electrolytic refiningCopper Mining Extraction Process Flow Chart Mining processing this flowchart made of machinery icons explains or expresses in simple but clear terms the step of the copper mining and copper extraction process starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral ore having a quick look now at how porphyry Mining Flow Chart On Copper ExtractionJan 01, 2009 The studied copper solvent extraction process consists of four units, three for extraction and one for stripping, as presented in Fig 2The inputs of the process are pregnant leach solution series and parallel flow rates, F(PLSS) and F(PLSP), pregnant leach solution copper concentration, c(PLS), lean electrolyte flow rate, F(LE), lean electrolyte copper concentration, c(LE), and the flow Control of an industrial copper solvent extraction process

Copper Mining and Processing: Everything you Need to Know

Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production Using today’s compact mining equipment, copper ore is extracted from the mine After the ore is crushed, it’s roasted, which helps to convert sulfides to oxidesDavenport, 1994) A flow diagram of the process is shown in figure 1 32 3 THE COPPER SX/EW PROCESS MONITORING APPLICATION In the application, the copper SX/EW process is A prototype of a process monitoring application for the copper SX/EW process was designed and implemented The application is based on steadyCopper SX/EWprocess monitoring systemCopper Mining Extraction Process Flow Chart,This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral ore Having a quick look now at how porphyry ores are treated and flow chart of extraction of copper

CONTROL OF AN INDUSTRIAL COPPER SOLVENT

Fig 1 Flow diagram of the copper solvent extraction process In the extraction units, copper is extracted from the pregnant leach solution to the organic solutionleach/solvent extraction/electrowinning (L/SX/EW) process for copper recovery, considered by some to be one of the great advances in copper recovery technology of the past 100 years1, satisfies these criteria Historical background When the sulphuric acid copper L/SX/EW flow sheet (Figure 1) was put forth by the MineralsCopper recovery using leach/solvent extraction JXSC mining equipment assisted Copper Extraction Process among mining industry, copper mining process with advanced crusher, concentrator, screen equipment The process flow is Crushing > Screening > Grinding > Concentration Description: The whole copper processing plant consist of 1 set Vibrating feeder, 1 set swing feeder, 1 set Copper Extraction Process JXSC Mining

(PDF) COMBINED ION EXCHANGE SOLVENT EXTRACTION PROCESS

Solvent Extraction Picture 1 depicts the overall process whereas L leaching, IXionexchange, SXsolvent extraction, In SX process an organic extractant that binds EW –electrowinning, Oore, Wspent ore, PLS copper but not impurity metals is dissolved in an pregnant leach solution, Ffiltrate, LRloaded organic solvent (diluent) and is Fig 1 General flow diagram of the copper solvent extraction process The copper transfer between the aqueous and organic phases takes place in mixers and the phases are separated in settlers The equipment used for the solvent extraction process varies considerably For example, in Outokumpu VSF technology the organicAN INDUSTRIAL COPPER SOLVENT EXTRACTION PROCESSCopper Mining Extraction Process Flow Chart,This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral ore Having a quick look now at how porphyry ores are treated and flow chart of extraction of copper

CONTROL OF AN INDUSTRIAL COPPER SOLVENT

Fig 1 Flow diagram of the copper solvent extraction process In the extraction units, copper is extracted from the pregnant leach solution to the organic solutionJun 28, 2017 The closest industrial process to the electrolytic copper extraction they hope to see is aluminum production by an electrolytic process known as HallHéroult process, which produces a pool of molten aluminum metal that can be continuously tapped “The ideal is to run a continuous process,” Chmielowiec saysA new way of extracting copper MIT News Massachusetts Jan 01, 2009 The studied copper solvent extraction process consists of four units, three for extraction and one for stripping, as presented in Fig 2The inputs of the process are pregnant leach solution series and parallel flow rates, F(PLSS) and F(PLSP), pregnant leach solution copper concentration, c(PLS), lean electrolyte flow rate, F(LE), lean electrolyte copper concentration, c(LE), and the flow Control of an industrial copper solvent extraction process

Dynamic modelling of an industrial copper solvent

copper concentrations of an industrial copper solvent extraction plant In this paper, the process is first briefly introduced, the modeling is then described in detail and, finally, the simulation results are presented and discussed 2 Process description Theaim of the copper solvent extractionprocessistoCopper Mining Extraction Process Flow Chart View Larger Image; This flowchart made of machinery icons explains or expresses in simple but clear terms the step of the Copper Mining and Copper Extraction Process Starting from either open pit or underground mining and using a different relevant treatment method for oxide or sulphide copperextraction process of copper from chalcopyriteextraction process were determined The positive value of ΔH obtained from temperature variation studies showed that the extraction process is endothermic The extraction of copper was lowest when chloroform was used as the diluent Separation and recovery of copper from a synthetic coppernickel solution containing 635 g/L Cu(II) and 058 g Liquidliquid extraction and separation of copper(II) and

Copper Mining and Processing: Everything you Need to Know

Mined from open pits, copper ore must be crushed as part of the process that occurs between extraction and production Using today’s compact mining equipment, copper ore is extracted from the mine After the ore is crushed, it’s roasted, which helps to convert sulfides to oxidesFlow sheet for copper extraction process Crushing, Grinding, Floatation are unit processes Roasting, smelting, Blowing, Refining, Electrolysis are Unit processes Flow sheet for iron and steel extraction process Flow sheet for Zinc extraction process Various reactors: a) Fixed bed reactor b) Shaft furnace c) FluidizedPrinciples of Extractive MetallurgyCopper electrowinning (EW) is an important process in connection with the solvent extraction to produce pure and marketable copper cathodes A phenomenological model A monitoring system for the copper solvent extraction

Improved dynamic modeling and simulation of an industrial

Dec 01, 2016 The studied solvent extraction process consists of three unit processes, two series mixer–settler units (E1, E2) for extraction of copper from the aqueous phase into the organic phase and one mixer–settler unit (S) for stripping of copper from the organic solution into the electrolyte solution, as shown in Fig 1As shown, the inputs of the process are the pregnant leach solution (PLS) or Copper mines are only set up where there is more than 5kg of copper per tonne of rock (05% by mass) Ideally, the figure should be closer to 2% The flow chart shows you how copper is extracted from its ore and converted into pure metalCopper mining The main stagesleach/solvent extraction/electrowinning (L/SX/EW) process for copper recovery, considered by some to be one of the great advances in copper recovery technology of the past 100 years1, satisfies these criteria Historical background When the sulphuric acid copper L/SX/EW flow sheet (Figure 1) was put forth by the MineralsCopper recovery using leach/solvent extraction