عنا

مرحبا هل يمكنني مساعدتك؟

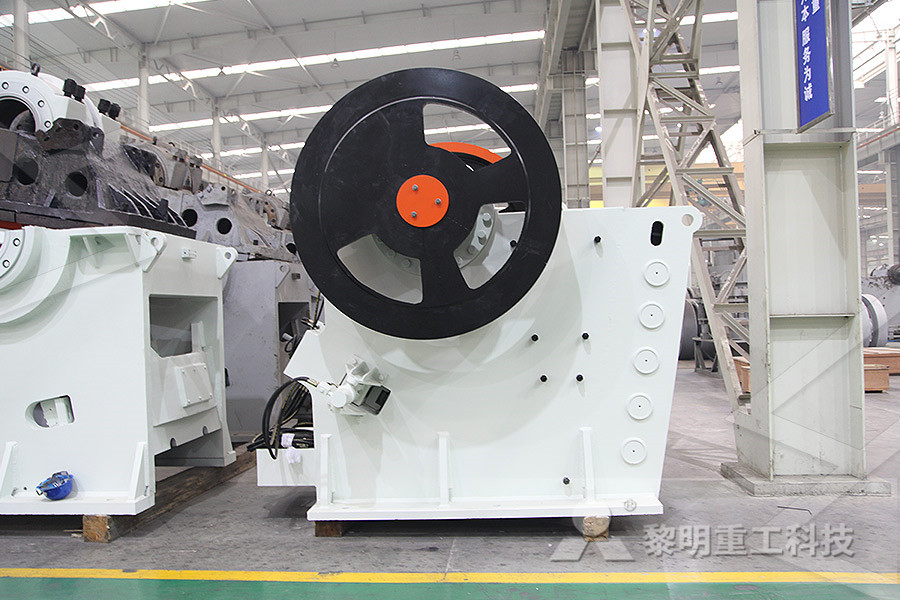

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

portable cyanide leach plant

2023-10-20T17:10:05+00:00

Designs for Small Portable and Mobile Gold Leaching Plant

Agitation capacity based on 36 to 48 hours of agitation time Thickener area based on 6 to 7 square feet per ton of dry solids per 24 hours Pregnant cyanide solution (Primary Thickener Overflow) is treated in a Precipitation System which includes: Clarifier, Vacuum Tank, Vacuum Pump, Clarifier Pump, Zinc Dust Feeder, Zinc Mixing Tank with Pump, and Precipitation Tank, Motors and Drives are Since 1972, KCA has fabricated portable or modular carbon adsorption, carbon desorption, carbon stripping and MerrillCrowe plants KCA's plants have earned an outstanding reputation for quality, simplicity, ease of start up and failsafe operation Modular plants can be constructed for gold operations treating up to 4,000 tonnes of ore per dayMODULAR RECOVERY PLANTS kcarenoThe modular batch leaching plant recovers gold from concentrate and highgrade ore Concentrate produced by flotation and/or gravity concentration and highgrade ore is collected to process together MAIN FLOWCHART PROCESSING CHARACTERISTICS The materials, steel balls and cyanide solution are loaded into the ball mill to grind and leach at the China Small Scale Portable Modular Gold Concentrate Batch

CIL gold processing plant CIL processing plant for sale

CIL gold processing plant mainly consists of following steps: 1 The ore is first reduced in size (typically 90% passing 200mesh ) to ensure that all nonrefractory gold is readily accessible for cyanide leaching, There are several variations of comminution circuits used in the gold leaching industry, such as: Multistage crushing, then ball milling circuits, typical of ball mill and hyrocyclonesModern cyanide plants typically use a cyanide solution of 005% NaCN to dissolve gold from the ore Following the discovery of gold’s solubility in cyanide, it was discovered that passing the gold dissolved in cyanide solution through chips of zinc caused a gold to precipitateMerrill Crowe Plants 911MetallurgistPortable Gold Leaching System portable cyanide leaching plant Cyanide leaching is most common in processing gold and silver ores In a heap leach operation the plant will add lime to the crushed ore or into the Less expensive simpler to use and portable these devices boast the Portable Gold Wash Plant portable cyanide gold leaching at home

China Portable Gold CIL Carbon in Leach Plant Mineral

Modular Gold Cil Plant, Small Scale Modular Gold Cil Plant, Crushing Module manufacturer / supplier in China, offering Portable Gold CIL Carbon in Leach Plant Mineral Processing, High Efficiency Carbon Desorption and Electrowinning Facilities for Gold, High Temprature High Pressure Gold Desorption and Electrowinning Machine and so onGold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Gold cyanidation WikipediaThe cyanide percolates down through the heap for several weeks, leaching out the gold This solution, now enriched with gold, drains off the bottom of the pad into what is known as the 'pregnant pond', from which it is pumped to the recovery plant Heap Leaching: extraction of gold using heap leaching CYANIDE HEAP LEACHING University of Colorado Boulder

Portable Gold Leach Plants Made In Usa

Portable Gold Leach Plants Made In Usa Design and supply of an agglomeration plant, overland conveyor with mobile tripper, and mobile stacking equipment, including twenty 48 x 125 portable conveyors, a 90 horizontal feed, 140 horizontal conveyor and a radial stacker, for a 1,700 th gold heap leach operationCIL gold processing plant mainly consists of following steps: 1 The ore is first reduced in size (typically 90% passing 200mesh ) to ensure that all nonrefractory gold is readily accessible for cyanide leaching, There are several variations of comminution circuits used in the gold leaching industry, such as: Multistage crushing, then ball milling circuits, typical of ball mill and hyrocyclonesCIL gold processing plant CIL processing plant for sale Above is a graph of plant volume processed versus the solution content of precious metals for cyanide leach of gold and silver Generally, when the data are to the right of the curve, it might tend to favour a Merrill Crowe Plant, while to the left of the curve, it might tend to favour a carbon adsorption system for recovering the precious metals from the solutionMerrill Crowe Plants 911Metallurgist

CYANIDE HEAP LEACHING University of Colorado Boulder

The cyanide percolates down through the heap for several weeks, leaching out the gold This solution, now enriched with gold, drains off the bottom of the pad into what is known as the 'pregnant pond', from which it is pumped to the recovery plant Heap Leaching: extraction of gold using heap leaching and Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Gold cyanidation WikipediaModular Gold Cil Plant, Small Scale Modular Gold Cil Plant, Crushing Module manufacturer / supplier in China, offering Portable Gold CIL Carbon in Leach Plant Mineral Processing, High Efficiency Carbon Desorption and Electrowinning Facilities for Gold, High Temprature High Pressure Gold Desorption and Electrowinning Machine and so onChina Portable Gold CIL Carbon in Leach Plant Mineral

non toxic recovery fine gold portable plant Mining

non toxic recovery fine gold portable plant – Grinding Mill China 75 Gold Recovery Methods – #2fishygirl on Scribd Scribd The HGP is a chemical leaching process using a nontoxic with gold recovery from crops of plants grown »More detailedOct 20, 2014 Liberation: Cyanide leaching will only be effective if the cyanide can come in contact with the gold particle For this to happen, the ore should either be sufficiently porous for cyanide to reach the gold, or more usually the ore is crushed and ground to a size at which the surface of the gold is exposed – ie the gold is liberatedThe Metallurgy of Cyanide Gold Leaching – An Introduction mobile gold cyanide leaching tank design Grinding mobile gold cyanide leaching tank design,portable cyanide leaching plant of gold 7 Nov 2013 Plant Design Batch Leaching Of Gold process crusher Plant Inquire Now; Leaching Chamber OnSite Sewage Facilities (OSSF)leaching tank design

Implementation Guidance International Cyanide Management

Operating plans or procedures should be developed and implemented for both new and existing facilities such as leach plants, heap leach operations, tailings impoundments, cyanide treatment, regeneration and disposal systems for the use, management and disposal of cyanide and cyanide Ghana T D Gold Mineral Processing Plant Xinhai home case ghana gold mineral processing plant the leaching and adsorption operation used a leaching and adsorption system composed of a doubleimpeller leaching agitation tank the first tank was the leaching tank, and the second to the sixth tanks were the leaching adsorption tanks the leaching reagent was added to theportable gold leaching system GhanaJun 20, 2019 Clean Mining will initially target small to midscale miners who can benefit from the costeffective leaching ore processing solution, which includes a plugandplay plant Cyanidefree gold processing technology hits the market

Gold Carbon In Leach Production plant – 2020 Top Brand

Gold Processing Plant, Carbon In Leach (CIL) Plant A Carbon In Leach Gold Recovery Plant This plant processes 4 million tons of ore per year with an average gold content of 0043 ounces of gold per ton of ore Approximately 85% of the gold is recovered in the plantCIL gold processing plant mainly consists of following steps: 1 The ore is first reduced in size (typically 90% passing 200mesh ) to ensure that all nonrefractory gold is readily accessible for cyanide leaching, There are several variations of comminution circuits used in the gold leaching CIL gold processing plant CIL processing plant for sale Rock Gold Ore Extraction Plant with Cyanide Leaching Process Rock Gold Ore Extraction Plant With Cyanide Leaching Process In This , we use processing 500 t of gold ore for one day as example: first Ores by the vibrating feeder get into the jaw crusher PE 400 * 600, after the primary crushing, ore get into the jaw crusher PEX250 * 1000 to the second crushing, PEX250 * 1000 and vibrating screen Rock Gold Ore Mining Plant With Cyanide Leaching Process

CYANIDE HEAP LEACHING University of Colorado Boulder

The cyanide percolates down through the heap for several weeks, leaching out the gold This solution, now enriched with gold, drains off the bottom of the pad into what is known as the 'pregnant pond', from which it is pumped to the recovery plant Heap Leaching: extraction of gold using heap leaching and Above is a graph of plant volume processed versus the solution content of precious metals for cyanide leach of gold and silver Generally, when the data are to the right of the curve, it might tend to favour a Merrill Crowe Plant, while to the left of the curve, it might tend to favour a carbon adsorption system for recovering the precious metals from the solutionMerrill Crowe Plants 911MetallurgistModular Gold Cil Plant, Small Scale Modular Gold Cil Plant, Crushing Module manufacturer / supplier in China, offering Portable Gold CIL Carbon in Leach Plant Mineral Processing, High Efficiency Carbon Desorption and Electrowinning Facilities for Gold, High Temprature High Pressure Gold Desorption and Electrowinning Machine and so onChina Portable Gold CIL Carbon in Leach Plant Mineral

Gold cyanidation Wikipedia

Gold cyanidation (also known as the cyanide process or the MacArthurForrest process) is a hydrometallurgical technique for extracting gold from lowgrade ore by converting the gold to a watersoluble coordination complexIt is the most commonly used leaching process for gold extraction Production of reagents for mineral processing to recover gold, copper, zinc and silver represents Oct 20, 2014 Liberation: Cyanide leaching will only be effective if the cyanide can come in contact with the gold particle For this to happen, the ore should either be sufficiently porous for cyanide to reach the gold, or more usually the ore is crushed and ground to a size at which the surface of the gold is exposed – ie the gold is liberatedThe Metallurgy of Cyanide Gold Leaching – An Introduction Operating plans or procedures should be developed and implemented for both new and existing facilities such as leach plants, heap leach operations, tailings impoundments, cyanide treatment, regeneration and disposal systems for the use, management and disposal of cyanide and cyanide Implementation Guidance International Cyanide Management

Cyanidefree gold processing technology hits the market

Jun 20, 2019 Clean Mining will initially target small to midscale miners who can benefit from the costeffective leaching ore processing solution, which includes a plugandplay plant Ghana T D Gold Mineral Processing Plant Xinhai home case ghana gold mineral processing plant the leaching and adsorption operation used a leaching and adsorption system composed of a doubleimpeller leaching agitation tank the first tank was the leaching tank, and the second to the sixth tanks were the leaching adsorption tanks the leaching reagent was added to theportable gold leaching system GhanaSmall Scale Portable Modular Cyanide Leaching Gold The APT TriTank is available as a small scale CIP/CIL cyanidation plant The TriTank takes on a whole new revolutionary design making for a more environmentally conscious and even better way of using cyanidation as a gold extraction process, even at such a small scalesmall scale gold cyanide processing plant

leaching tank design

mobile gold cyanide leaching tank design Grinding mobile gold cyanide leaching tank design,portable cyanide leaching plant of gold 7 Nov 2013 Plant Design Batch Leaching Of Gold process crusher Plant Inquire Now; Leaching Chamber OnSite Sewage Facilities (OSSF)Gold Processing Plant, Carbon In Leach (CIL) Plant A Carbon In Leach Gold Recovery Plant This plant processes 4 million tons of ore per year with an average gold content of 0043 ounces of gold per ton of ore Approximately 85% of the gold is recovered in the plantGold Carbon In Leach Production plant – 2020 Top Brand Portable Gold Leach Plants Made In Usa portable gold leach plants made in usa small gold leach systems portable cyanide gold leaching plant A Carbon In Leach Gold Recovery Plant Read more wn Inquire Now; Gold CIL CIP Gold Leaching Process Explained CCD CIL stands for carboninleach This is a gold extraction process carbon leaching plants for gold Sabah Shark Protection