عنا

مرحبا هل يمكنني مساعدتك؟

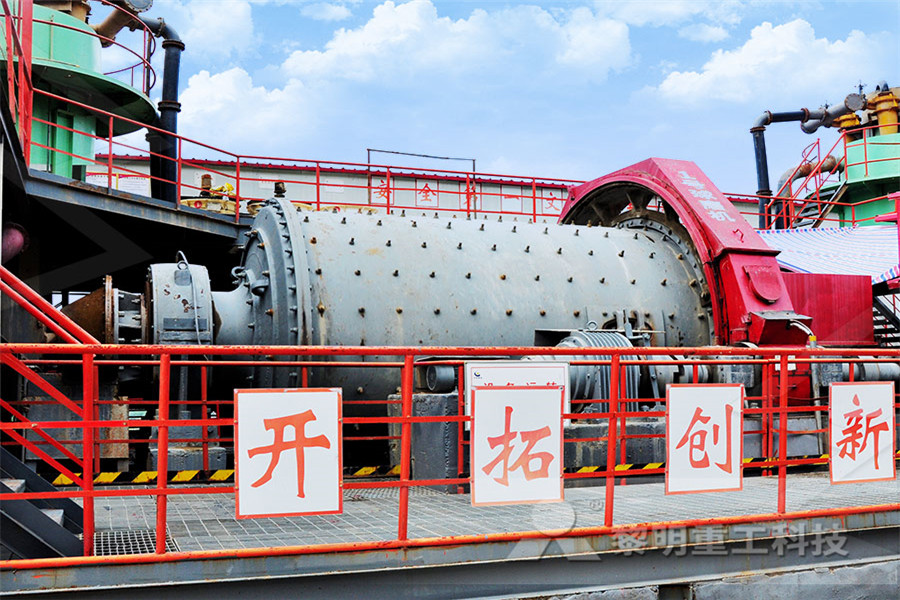

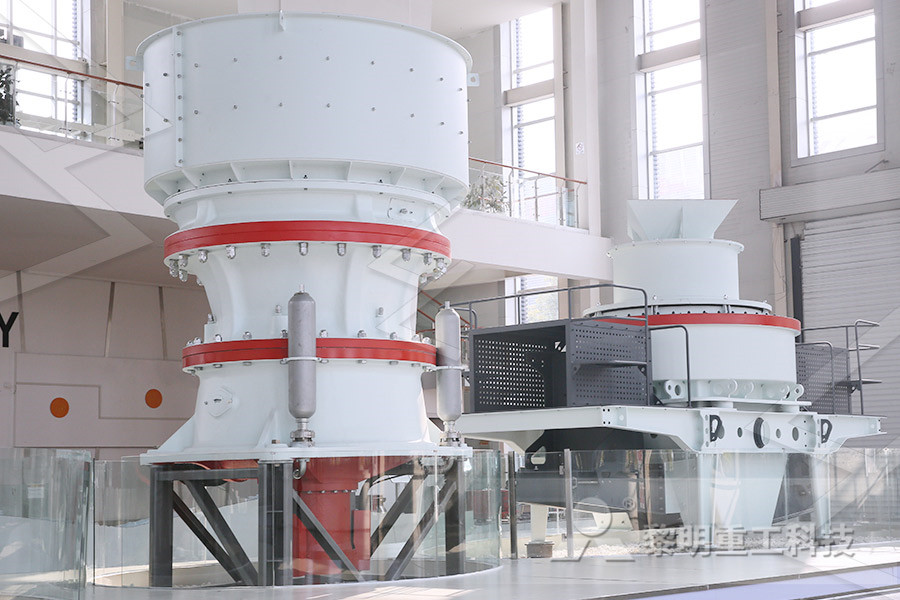

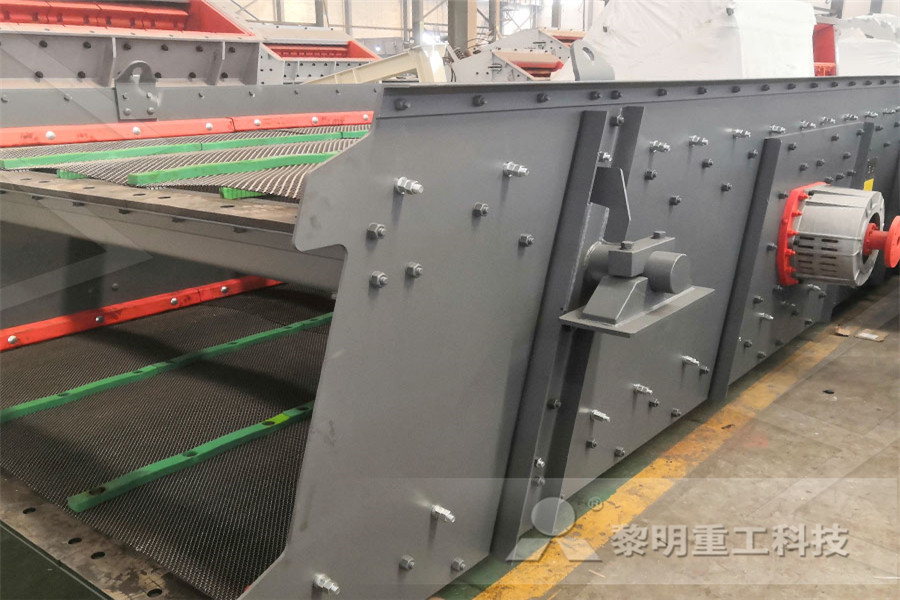

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

induced roll magnetic separator

2019-06-04T06:06:51+00:00

Induced Magnetic Roll Separator IMR Bunting Redditch

The Induced Roll Magnetic Separator (IMR) is proven technology for purifying dry nonmetallic minerals used in the ceramics and glass industries The IMR uses electromagneticallygenerated high intensity magnetic fields to continuously separate small paramagnetic particles from materials with a particle size range between 2mm to 45 micronsInduced Roll Magnetic Separator by Bunting Bunting’s Induced Roll Separator offers continuous extraction of magnetic particles for optimal mineral purification The induced roll separator continuously extracts small magnetic particles from minerals being processed, resulting in a final mineral product of exceptional purityInduced Roll Separator Magnetic Separation BuntingThe “Reading” Pilot Induced Roll Magnetic Separator is specifically designed for the highly selective dry magnetic separation of samples of dry granular materials As the machine represents a fullscale crosssection of a fullscale production model, direct performance comparisons and machine settings are possible Features The separation Induced Roll Magnetic Separator Mineral Technologies

Laboratory High Intensity Induced Roll Magnetic Separator

The top fed induced roll separator places all materials in contact with the highest magnetic field at the zones of steepest magnetic gradient and utilizes magnetic force Professor Neil Rowson presents a technical overview of the Induced Roll Magnetic Separator (IMR) The IMR is used widely in the mineral processing industry Induced Roll Magnetic Separator Technical Overview by Prof The Induced Roll Magnetic Separator (IMR) uses electromagneticallygenerated high intensity magnetic fields to continuously separate small paramagnetic particles from materials with a particle size range between 2mm to 45 microns The IMR comprises of an electromagnetically induced steel roll positioned between a bridge bar and pole pieceRare Earth Roll or Induced Magnetic Roll Bunting Redditch

Particle flow modeling of dry induced roll magnetic separator

Aug 01, 2013 The induced magnetic roll separator consists of a revolving laminated roll formed of alternate magnetizable and nonmagnetic disks The roll is placed between specially shaped poles of an electromagnet and the electromagnet induces a magnetic field in the magnetic laminations of a roll forming local regions of high magnetic field gradientsLaboratory High Intensity Induced Roll Magnetic Separator, MIH (13) × ) Request Pricing Info The Model MIH(13)1115 is a TOP FED laboratory or pilot plant dry high intensity magnetic separator, is designed to separate moderately or weakly magnetic (para magnetic) materials Laboratory High Intensity Induced Roll Magnetic Separator Magnetic Separation Equipment Davis Tube Tester; High Intensity Magnetic Separator Induced Roll “Lift Type” Laboratory Model, MLH (13) 1115; Laboratory Electrostatic Separator Model EHTP (25) 11115; Laboratory Rare Earth Roll Magnetic Separator L/P 1030; Laboratory Model L8 Wet Drum Magnetic SeparatorHigh Intensity Lab Magnetic Separator Induced Roll “Lift

Induced Magnetic Roll Seperator (IMRS) Equipment HMD

Induced Magnetic Roll Seperator HMD magnetic separation equipment is ‘Next Generation’ – Our equipment features have been brought back to basics in most operational areas We have addressed many of the inherent complexities in the existing designs which has brought about a cost competitive alternative to the 1980’s design READING unitsCarpco Model MIH(13)1115 Laboratory HighIntensity InducedRoll Magnetic Separator is a topfed laboratory/pilotplant dry highintensity electromagnetic separator designed to separate paramagnetic (weakly magnetic) materials from nonmagnetic materials This CARPCO MODEL MIH(13)1115 LABORATORY HIGH The Mastermag induced roll magnetic separator is used for the continuous extraction of small magnetic particles from certain minerals to produce mineral purification for a wide range of mineral and ceramic processing industries The material being treated is fed from a hopper or vibratory feeder at a induced roll magnetic separator Equipment Environmental

Separation analysis of dry high intensity induced roll

Sep 01, 2014 A dry induced roll magnetic separator is simple and efficient for upgrading the magnetic mineral and materials Weak paramagnetic minerals can be effectively removed from an ore by maintaining the field intensity up to ~ 25 T , IRMS as shown in the Fig 1 consists of a horseshoe magnet faced by an iron bridge bar and of two rolls, one opposite each poleMagnetic gangue removal from cassiterite, tungsten ores, glass sands and a variety of industrial products Induced Roll Magnetic Separators (IRMS) The IRMS separator range includes two start twinpass configurations in 133 or 160 millimetre roll diameter, of up to Reading Magnetic Separators Mineral TechnologiesLIFTTYPE INDUCED ROLL MAGNETIC SEPARATOR AND SEPARATION METHOD United States Patent Inventors: Grieve, Robert B Carpenter, James Hall Application Number: USDA Publication Date: 04/07/1970 Filing Date: 12/04/1967 Export Citation: Click for automatic bibliography generation LIFTTYPE INDUCED ROLL MAGNETIC SEPARATOR AND SEPARATION

Multi Gravity Mozley Separator Drum 911Metallurgist

Highintensity inducedroll magnetic separator treats from 1 mm down to 74 µm in size and boasts a capacity of up to 90 kg/h based on material having a bulk density of 1600 kg/m³, variable magnetic field intensity up to 096 T, 127 mm diameter and 508 mm length laminated roll with variable speed 0100 rpm (Ibrahim et al, 2002)•Induced roll magnetic separator Magnetic field gradient, fractions 12 Magnetic pulleyj • Setr of stationary magent cover 50 to 75% of drum circumference Magnetic material, under the action of magnetic field, adhjere to the drum or pulley and move along the pulley as long as theMECHANICAL SEPARATION TECHNIQUESInduced roll magnetic separators (IRM) Lift roll magnetic separators Cross belt magnetic separators Disc magnetic separators Eddy Current Separator Magnetic Separator Applications Magnetic Separators have long been used to upgrade and beneficiate a wide variety of minerals and materials Magnetic Separators can be applied in mainly three ways:How Does a Magnetic Separator Work GTEK Magnet

Eriez Magnetic Separation

Eriez Permanent Magnetic Separators require no electric power With proper care, they can last a lifetime with very little loss of magnetic field strength Eriez permanent magnets are supplied for a wide range of applications including dry bulk materials, liquids or An electromagnetic induced magnetic roll separator has an air gap, which must be increased to accommodate the processing of larger particles The rareearth magnetic roll (REMR) magnetic separator has no such air gap Consequently, the magnetic force does not decline in the manner of an IMR set with a large air gap Magnetic Separators 911MetallurgistInduced roll magnetic separators (IRM) Examples of these dry separators are the Readings IRM manufactured by Mineral Technologies They are commonly used to separate ilmenite from less magnetic and non magnetic in dry mills The Readings IRM consists of an electromagnet which induces a magnetic field onto a serrated rotating roll via a cast iron Magnetic Separation ttms999

induced roll magnetic separator Equipment Environmental

The Mastermag induced roll magnetic separator is used for the continuous extraction of small magnetic particles from certain minerals to produce mineral purification for a wide range of mineral and ceramic processing industries The material being treated is fed from a hopper or vibratory feeder at a Induced roll magnetic separators (IRM) Lift roll magnetic separators Cross belt magnetic separators Disc magnetic separators Eddy Current Separator Magnetic Separator Applications Magnetic Separators have long been used to upgrade and beneficiate a wide variety of minerals and materials Magnetic Separators can be applied in mainly three ways:How Does a Magnetic Separator Work GTEK MagnetHighintensity inducedroll magnetic separator treats from 1 mm down to 74 µm in size and boasts a capacity of up to 90 kg/h based on material having a bulk density of 1600 kg/m³, variable magnetic field intensity up to 096 T, 127 mm diameter and 508 mm length laminated roll with variable speed 0100 rpm (Ibrahim et al, 2002)Multi Gravity Mozley Separator Drum 911Metallurgist

Dry High Intensity Magnetic Separators (DHIMS) Eriez Lab

Eriez’ Rare Earth Roll Separators provide an alternative in handling a wide variety of materials which do not respond well to traditional methods of processing on low intensity dry drum separators or high intensity induced magnetic roll separatorsLIFTTYPE INDUCED ROLL MAGNETIC SEPARATOR AND SEPARATION METHOD United States Patent Inventors: Grieve, Robert B Carpenter, James Hall Application Number: USDA Publication Date: 04/07/1970 Filing Date: 12/04/1967 Export Citation: Click for automatic bibliography generation LIFTTYPE INDUCED ROLL MAGNETIC SEPARATOR AND SEPARATION Inducedroll magnetic separators IRM separators have historically been used in mineral sands processing Some remain in various mineral sands circuits but RER separators are rapidly replacing them The RER allows mineral processors to get over 50% greater capacityA discussion of magnetic separation techniques for

MECHANICAL SEPARATION TECHNIQUES

•Induced roll magnetic separator Magnetic field gradient, fractions 12 Magnetic pulleyj • Setr of stationary magent cover 50 to 75% of drum circumference Magnetic material, under the action of magnetic field, adhjere to the drum or pulley and move along the pulley as long as theRoll Magnetic Separator is a roll type dry magnetic separator with fixed magnet having high field intense and gradient The magnets used in the Roll Magnetic Separators and made of alloys of rare earth elements are more powerful as compared to other magnets They generate high attraction forces on the magnetic roll due to theirMagnetic Roll Separator Magnetic Roller Separator Latest How is the magnetic field created in induced roll magnetic separators?) permanent magnets by using two sizes of lamination, the roll is given a serrated profile) the unevenness promotes high field intensity and gradient of the magnetic fieldMagnetic Separation (Wills' Mineral Processing Technology

Crossbelt Magnet Separators Tuffman Equipment

Produce the purest commodity by separating ferrous metal contamination from nonferrous products! Crossbelt Magnet Separators (CBS) are available in 18 inch, 24 inch, 30 inch, 36 inch, 42 inch, 48 inch, and 60 inch models Crossbelt magnet separators are ideal for recycling operations to sort comingled metals and separate various metals from the recycling streamInduced Roll Separators are primarily used for separating or concentrating minerals or materials of low magnetic susceptibility Uses include extraction of iron or chromium bearing minerals from silica sand, the concentration minerals such as wolframite, the removal of paramagnetic minerals such as Iron Titanium Oxide (Ilmenite, FeTiO3), Iron Carbonate (siderite, FeCO3), etc, from valuable Magnetic Roll Separators Magnetic Roll Separator Rare Earth Masteroll Separator Features: • Composite highintensity magnetic head pulley utilizes neodymium magnets, the most powerful permanent magnets available • Magnetic rolls are available in 295 inch, 590 inch, and 787 inch diameters, up to a width of 328 feetRare Earth Masteroll Separator Bunting Magnetics Co

Alibaba Manufacturer Directory Suppliers, Manufacturers

Ouch You have clicked a page that seems to be very popular It’s currently a bit busy You can have a rest and please slide to verifyInduced roll magnetic separator is found to be an effective dry separator for the separation of fine particles Separation efficiency of this separator depends on mineral characteristics and the Sunil TRIPATHY Postdoctorate Fellow PhD (Mineral