عنا

مرحبا هل يمكنني مساعدتك؟

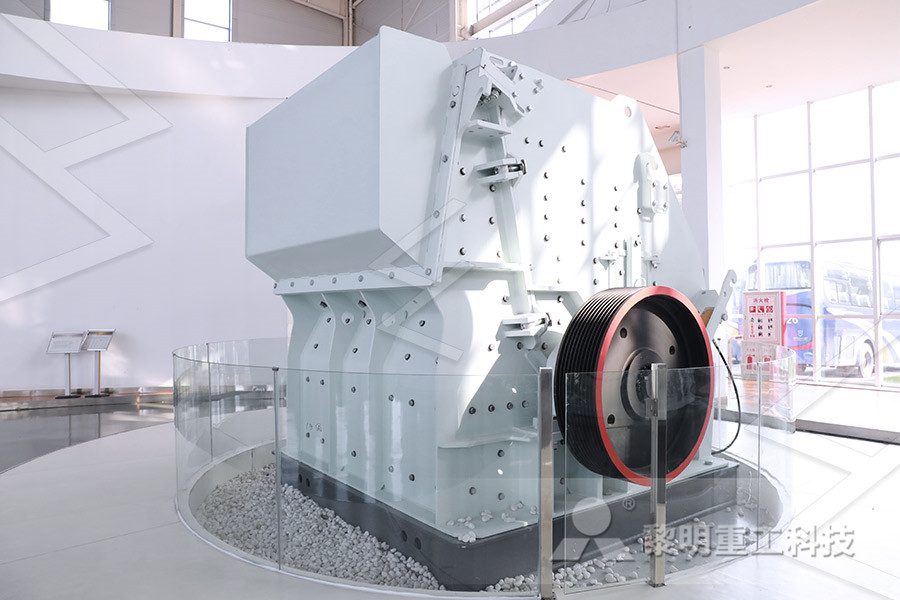

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

cement rotary kiln rotary kiln rotary cement

2020-11-09T14:11:46+00:00

Cement Rotary Kiln Rotary Kiln Rotary Kiln

Cement rotary kilns refer to cement rotary calcining kilns (sometimes called rotary furnaces) It is a pyroprocessing device used to heat materials to high temperatures in a continuous process The kiln body is a cylinder vessel with a certain degree of tilt to the horizontal levelThe rotary cement kiln is the most vital device in a cement plant, it is the place where the raw meal is burnt and calcined into clinker Cement rotary kiln plays a variety of roles in the cement production line at the same time It is not only a combustion device, but also a heat exchange device, a chemical reactor, and a conveying deviceRotary Cement Kiln Manufacturer Rotary Kiln for Cement Cement rotary kiln, also called clinker kiln, can be divided into dryprocess cement kiln and wetprocess cement kiln according to the cement production technology Dryprocess cement rotary kiln is mainly used to calcine cement clinkerCement Rotary Kiln, Rotary Kiln Cement Kiln AGICO Cement

Cement Kiln Is Our Hot Sales And The Rotary Cement Kiln's

Cement rotary kiln turns into micro running under high temperature The maintain of attachment devices and the level of the thermal system is closely related to cement kiln’s safety and efficiencyChinese leading rotary kiln supplier AGICO manufactures all kinds of rotary kiln products for various industries, such as cement production plant, construction, chemicals and metallurgy The main products include cement kiln, lime rotary kiln and moreRotary Kiln Top Kiln Manufacture Of Rotary Kiln, Cement Mar 23, 2020 In general, the process of cement rotary kiln is crushed, batched, and ground to make raw materials, then homogenized, and then slowly calcined mature materials in the cement rotary kiln After the finished product, it can be sent to the material end /by 管理员Analysis of the process of cement rotary kiln LCDRI CN

Cement Rotary Kiln,Rotary Cement KilnChina Machinery

The rotary cement kiln belongs to building equipment such as chemical rotary kiln and active lime rotary kiln According to different materials, there are cement kiln, metallurgy chemical kiln modern cement plant The 2base rotary kiln is a statically determined beam system, where the support load is always known It is a shorter and wider kiln, with a reduced slope to maintain the material retention time, similar to a 3base kiln The larger diameter reducesRotary kilns for cement plants With the arrival of rotary kilns, cement manufacturing processes became sharply defined as wet process or dry process In the Wet Process, the kiln system is fed with a rawmix in the form of a liquid slurry, typically containing 3050% of water by mass In the Dry Process, the kiln system is fed with a rawmix in the form of a dry powderCement Kilns: Early rotary kilns

Cement Rotary Kiln, Rotary Kiln Cement Kiln AGICO Cement

Cement rotary kiln is a piece of cement equipment with strong durability, also plays a vital role in the cement plant If you find any problem in the operation, solve it immediately In general, the maintenance of rotary kiln is a complex process, here are some tips will be helpfulMar 23, 2020 Firing of cement clinker In the rotary kiln, the carbonate is further rapidly decomposed and a series of solid phase reactions occur to generate cement clinker After a series of chemical reactions, the high temperature clinker discharged from the rotary kiln is cooled by the cement Analysis of the process of cement rotary kiln LCDRI ement rotary kiln process description As the main equipment of dry process cement clinker production line plant, which is the most efficient clinker calcining equipment LCDRI cement rotary kiln can meet the construction requirement of 100012000 tpd cement production line plant, with the advantage of easy operation, high output and smooth Cement rotary kiln LCDRI CN

Cement kiln Wikipedia

The rotary kiln systems of the cement industry destroy these trace components virtually completely [citation needed] Polycyclic aromatic hydrocarbons (PAH) PAHs (according to EPA 610) in the exhaust gas of rotary kilns usually appear at a distribution dominated by naphthalene, which accounts for a share of more than 90% by mass The rotary Rotary kiln (large rustcolored horizontal tube at center right) at a Wyoming cement plant General layout of a direct fired countercurrent rotary kiln used in cement manufacture Rotary kiln body, with drive gear and 2 tyres (riding rings)Rotary kiln WikipediaA cement rotary kiln consists of a slightly inclined tube made from steel plate and lined with refractory brick The refractory is used to insulate the steel structure, which becomes soft and weak above 800 C The kiln rotates between 30 and 250 revolutions per hour, taking in a raw mix at the upper endFailure Analysis of Cement Rotary Kiln During Startup

Introduction of rotary kiln structure

Rotary kiln (rotary kiln) generally has 2 to 3 sets of rollers RollerSupport Wheel Set The thrust roller is the limit switch that limits the time when the rotary kiln (rotary kiln) feed Because the support roller is wider than the kiln tire, in order to make the roller and the belt move up and down, the wear is evenAccording to different fuels, rotary kiln can be classified into gasfired rotary kiln, oilfired rotary kiln and coalfired rotary kiln It is widely used for different materials with a processing capacity of 1801, 000 tons per day, a dimension ofφ25×40mφ48×68m and cement production capacity of 501000t/d, being easy to operate and Cement KilnRotary kiln,rotary dryerHongke Heavy The cement clinker rotary kiln is the main equipment for cement clinkers calcining in chemical industry, metallurgy industry, etc Through technological innovations, the calcination system of this cylindrical calcinator has been equipped with the most advanced hydraulic thrust roller in the world and various advanced devices in China, including highly accurate measuring plunger pump, greatly Cement Clinker Rotary KilnRotary KilnChina Sunlike

Cement Kilns: Rotary Coolers

Rotary coolers for use with cement kilns One way of shortening the cooler so that the second kiln pier need not be pierced was the "doubleback" or "concentric" cooler, produced by several manufacturers in the period 19051920The later versions were frequently supplied with pressurisation airRotary Cement Kiln Process Kiln feed for a wet process kiln has a water content of approximately 40% In the charging zone of a wet process kiln, steel chains are used as heat exchangers in the drying process Chains extract heat from the kiln’s hot exhaust gases to dry the slurry feedCement Kiln Refractory for Charging, Calcining Burning A rotary kiln for calcination of light aggregate cement comprises a calcination kiln body, a heavyoil combustion device, and a cooling device, wherein the calcination kiln body is formed in a Uturn for saving construction site and is composed of a feeding entrance at its upmost end, a product exit at the lowest end, and a plurality of revolving segments varied in caliber by segment so as to USB1 Rotary kiln for calcination of light

USA Rotary cementkiln Google Patents

kiln gun rotary valve aggregates Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Lifetime Application number USA Inventor Thomas A Edison Original Assignee Jiangsu Pengfei group rotary kiln is widely used in cement, metallurgy, chemical industry, environmental protection and other industries Pengfei rotary kiln uses rotary kiln as smelting equipment to sinter and roast iron, aluminum, copper, zinc, tin, nickel, tungsten, chromium, file and other metals in nonferrous metal smelting and processing industryRotary kiln, Wet Rotary Kiln, Rotary Kiln, Dry Rotary Kiln Mar 23, 2020 Firing of cement clinker In the rotary kiln, the carbonate is further rapidly decomposed and a series of solid phase reactions occur to generate cement clinker After a series of chemical reactions, the high temperature clinker discharged from the rotary kiln is cooled by the cement Analysis of the process of cement rotary kiln LCDRI CN

Rotary kiln Wikipedia

Rotary kiln (large rustcolored horizontal tube at center right) at a Wyoming cement plant General layout of a direct fired countercurrent rotary kiln used in cement manufacture Rotary kiln body, with drive gear and 2 tyres (riding rings)rotary kiln is Let us explain these points briefly: 1 Age and condition of the rotary kiln shell: Old kilns shells have been exposed to creep for a long time and are more prone to develop fatigue cracks than newer shells 2 Distance between tires: The longer the rotary kiln shell span, the less it will resist high temperatures without saggingROTARY KILN Some questions and answers of CEMENTCement Rotary Kiln Description of Cement Rotary Kiln: As the main equipment in both of the cement clinker dry and wet process production lines, this cement rotary kiln is widely used in metallurgy field, chemical industry, building refractory material sector, environmental protection field, and so on It mainly consists of cylinder body, supporting device, supporting device with catch wheel Rotary Kiln,Cement Rotary Kiln,China Rotary Kiln Manufacturer

Cement rotary kiln SlideShare

Jun 22, 2018 Cement rotary kiln 1 QATAR NATIONAL CEMENT COMPANY Cement Rotary Kiln Questions Answers By: Nael Shabana qatarcement@yahoo 2013 2 1 “In the name of Allah, the Beneficent, the Merciful” “Read in the name of thy Lord Who creates Creates man from a clot Read and thy Lord is most Generous Who taught by the pen Taught man what he kiln gun rotary valve aggregates Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Expired Lifetime Application number USA Inventor Thomas A Edison Original Assignee USA Rotary cementkiln Google PatentsThe cement clinker rotary kiln is the main equipment for cement clinkers calcining in chemical industry, metallurgy industry, etc Through technological innovations, the calcination system of this cylindrical calcinator has been equipped with the most advanced hydraulic thrust roller in the world and various advanced devices in China, including highly accurate measuring plunger pump, greatly Cement Clinker Rotary KilnRotary KilnChina Sunlike

USB1 Rotary kiln for calcination of light

A rotary kiln for calcination of light aggregate cement comprises a calcination kiln body, a heavyoil combustion device, and a cooling device, wherein the calcination kiln body is formed in a Uturn for saving construction site and is composed of a feeding entrance at its upmost end, a product exit at the lowest end, and a plurality of revolving segments varied in caliber by segment so as to Rotary coolers for use with cement kilns One way of shortening the cooler so that the second kiln pier need not be pierced was the "doubleback" or "concentric" cooler, produced by several manufacturers in the period 19051920The later versions were frequently supplied with pressurisation airCement Kilns: Rotary CoolersA rotary kiln for cement is only as efficient as the seals on its inlet and outlet zones After all, if false air enters the kiln system, fuel consumption goes up, production output goes down, and operating expenses skyrocket The ROTAX2’s impressive graphite seals use a staggered arrangementHighproduction, low maintenance rotary kiln

The use of scrap tires in cement rotary kilns

Cement Rotary Kiln International Cement Review CEMENT ROTARY KILN Questions Answers Question1 What is the maximum continuous shell temperature a kiln stands without permanent damage to the shell Answer1 The maximum remended kiln shell temperature varies by plant by country and by kiln manufacturer despite the fact that most kiln shells are made of low alloy carbon steelPengfei brand rotary kiln is the main equipment for calcining cement clinker and it can be used widely for cement industry, metallurgy industry, chemical industry, etc The rotary kiln is composed of the shell, the supporting device, the supporting device with thrust roller, the driving device, the movable kiln head, the sealing device at kiln Cement rotary kilnThe rotary kiln is widely used in metallurgical,chemical,building refractory material, environmental protection industry Structure of Cement Rotary Kiln The cement rotary kiln is composed of a cylinder body, transmission device,supporting device,supporting roller,kiln,kiln tail seal,kiln Rotary Kiln/Cement Rotary KilnHongji Group

Rotary Cement Kiln Simulator (RoCKS): Integrated modeling

May 01, 2007 The main key issues for modeling the rotary cement kilns are estimating the residence time of solids in the kiln, cinkerization reaction in bed region, coal combustion in freeboard region, heat transfer between bed freeboard and walls, melting/coating formation around the kiln walls