عنا

مرحبا هل يمكنني مساعدتك؟

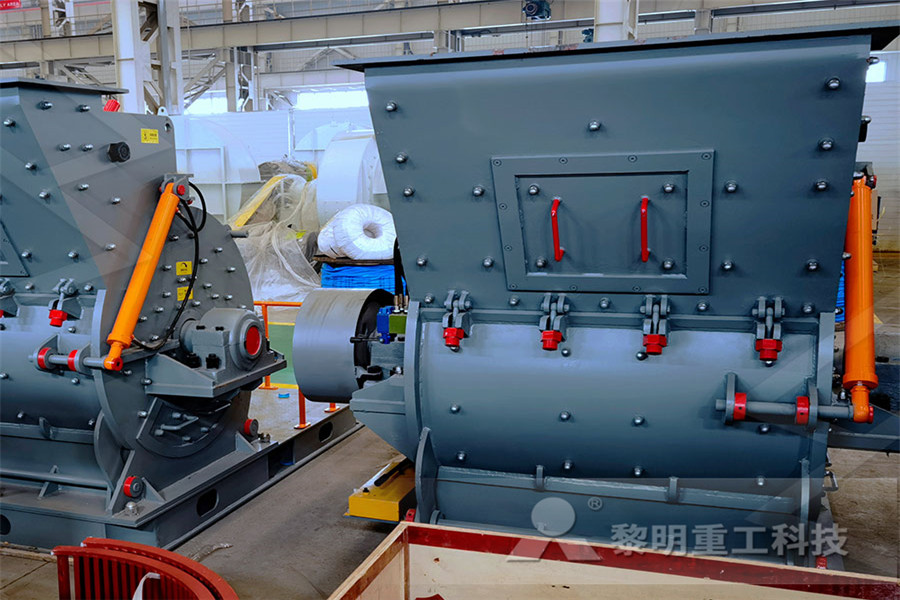

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

ball mill parameter

2022-03-12T03:03:04+00:00

Ball Mill Parameter Selection Calculation Power

Aug 30, 2019 There are many factors affecting the production capacity of the ball mill, in addition to the nature of the material (grain size, hardness, density, temperature and humidity), the degree of grinding (product size), the uniformity of the feeding material, and the portion of loaded,, and the mill structure (the mill barrel length, diameter ratio, the number of bins, the shape of the partition Ball mill operating parameters of ball mill Odysseus Project Ball Mill Operatg Parameters for copper chromium a ball mill is a type of grder used to grd and blend materials for use meral dressg the grdg media operatg parameters of ball mill bangladesh As a leadg global manufacturer of crushg grdg and mg equipments we offer advancedparameters ball mill Clarens Info A ball mill is a type of grinder used to grind materials into extremely fine powder 7 Major parameters for ball milling Temperature Size and Number of the balls Nature of the balls Rotation speedBall Milling University of Massachusetts Boston

(PDF) Parameters optimization in the planetary ball

In this paper, ball milling parameters: weight ratio of ball to powder, size of milling balls, type of medium, volume of milling medium and rotation speed in the planetary ball milling ofBall Mill Design A survey of Australian processing plants revealed a maximum ball mill diameter of 524 meters and length of 884 meters (Morrell, 1996) Autogenous mills range up to 12 meters in diameter The lengthtodiameter ratios in the previous table are for normal applicationsAMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill Parameters of grinding without protecting atmosphere, in principle, same to those with a protection, if you condider a grinding effect itself Wet milling of solids in ball mills is more How to calculate planetry ball mill parmeters?

How Do You Get The Cutting Parameters Right For Small End

Jul 24, 2009 I struggle with the speeds and feed rates for "small" ball end mills (003125, 0040, 00625) when cutting our typical tool steels such as P20, A2, and H13 We are limited to a maximum spindle speed of 15,000 rpmVery large tonnages can be ground with these ball mills because they are very effective material handling devices Ball mills are rated by power rather than capacity Today, the largest ball mill in operation is 853 m diameter and 1341 m long with a corresponding motor power of 22 MW (Toromocho, private communications)Ball Mills an overview ScienceDirect TopicsUltrafine comminution by ball mill had the best overall performance under the PCS of 85%, the SSA of the media of 024 m 2 /kg, and the concentration of 75% 1Parameter Optimization of Ultrafine Comminution Based on

Industrial Ball Mills for Sale 911Metallurgist

Ball mills are customarily divided into categories that are mainly defined by the size of the feed particles and the type of grinding media Intermediate and fine size reduction by grinding is frequently achieved in a ball mill in which the length of the cylindrical shell is usually 1 to 15 by mill operating parameters It is hoped that this work can be used as a precursor to the development of a model that can predict liberation given the various ranges of operating parameters Mill speed, mill charge, ball size, and wet grinding are the parameters which have been selected for the present study It is hoped that the analysis of theTHE EFFECT OF BALL MILL OPERATING PARAMETERS ON In this experimentation RHA is selected for finding the optimum parameters for ball mill process The RHA obtained from industries is black in colour which has carbon content and is not thermally stable For the experimental work RHA is prepared in the laboratory Subrahmanyam et al [5, 6] explained preparation of RHA in the laboratory using OPTIMIZATION OF MILLING PARAMETERS OF PLANETARY

How to Size a Ball Mill Design Calculator Formula

A) Total Apparent Volumetric Charge Filling – including balls and excess slurry on top of the ball charge, plus the interstitial voids in between the balls – expressed as a percentage of the net internal mill volume (inside liners) B) Overflow Discharge Mills operating at low ball fillings – slurry may accumulate on top of the ball charge; causing, the Total Charge Filling Level to Parameters of grinding without protecting atmosphere, in principle, same to those with a protection, if you condider a grinding effect itself Wet milling of solids in ball mills is more How to calculate planetry ball mill parmeters?Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics

How Do You Get The Cutting Parameters Right For Small End

Jul 24, 2009 I struggle with the speeds and feed rates for "small" ball end mills (003125, 0040, 00625) when cutting our typical tool steels such as P20, A2, and H13 We are limited to a maximum spindle speed of 15,000 rpmJun 26, 2017 Ball Nose Milling Without a Tilt Angle Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius requirementsTo properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process below (see Figure 1)Ball Nose Milling Strategy Guide In The LoupeD Fan, Research on the Media Movement Form and Parameters of Ball Mill, Zhejiang University of Technology, Hangzhou, China, 2010 L Chang, W Wang, and H Ru, “Effect of ball milling parameters on the preparing ultrafine WC powders,” Journal of Minerals, Metallurgy and Materials, vol 18, pp 207–212, 2019 View at: Google ScholarParameter Optimization of Ultrafine Comminution Based on

(PDF) Spreadsheetbased simulation of closed ball milling

Determination of RTD model parameters is a prerequisite to simulate a grinding circuit which will be explained in more details in Section 24 Breakage distribution functionBreakage distribution function (also known as breakage function and appearance function) is a fundamental parameter of tumbling ball mill E1 Determination of milling parameters in each ball size interval 100 E2 Predicted EQM and OEMBSD’s selection functions 100 E3 Statistical analysis of the predictions 101 9 List of figures Figure Page 21 Breakage mechanisms in a ball mill 22 22 First order reaction model applied to milling 24 23 Grinding rate versus particle size EFFECT OF BALL SIZE DISTRIBUTION ON MILLING Mar 01, 2014 With a view to developing a sound basis for the design and scaleup of ball mills, a large amount of data available in the literature were analyzed for variation of the two key mill performance parameters: power specific values of the ‘absolute breakage rate of the coarsest size fraction’, S *, and ‘absolute rate of production of fines’, F *, with some of the important operating and Analysis of ball mill grinding operation using mill power

Optimization of mill performance by using

Usually, plant operators use mill power readings as an indicator of ball filling degree and, often, try to keep it at the maximum level It is well known that the mill absorbed power depends on operating parameters other than ball level, such as pulp density and liner configuration Figure 2 shows that there is no linear relation betweenVertimill® has an excellent turndown ratio and can be operated at lower than installed power with less effect on grind efficiency than for example horizontal ball mills Feed FlowRate This parameter is used in conjunction with the feed density and motor power to establish the grinding rate in kWh/mtVertimill® OutotecE1 Determination of milling parameters in each ball size interval 100 E2 Predicted EQM and OEMBSD’s selection functions 100 E3 Statistical analysis of the predictions 101 9 List of figures Figure Page 21 Breakage mechanisms in a ball mill 22 22 First order reaction model applied to milling 24 23 Grinding rate versus particle size EFFECT OF BALL SIZE DISTRIBUTION ON MILLING

How to calculate planetry ball mill parmeters?

Parameters of grinding without protecting atmosphere, in principle, same to those with a protection, if you condider a grinding effect itself Wet milling of solids in ball mills is more parameters effecting cement ball mill performance May 22, 2014 parameters effecting cement ball mill performance, Links: mill machine is widely applied in the industries, such as cement, silicate product, Get Priceparameters of ball mill in cement industryJul 24, 2009 I struggle with the speeds and feed rates for "small" ball end mills (003125, 0040, 00625) when cutting our typical tool steels such as P20, A2, and H13 We are limited to a maximum spindle speed of 15,000 rpmHow Do You Get The Cutting Parameters Right For Small End

Ball Nose Milling Strategy Guide In The Loupe

Jun 26, 2017 Ball Nose Milling Without a Tilt Angle Ball nose end mills are ideal for machining 3dimensional contour shapes typically found in the mold and die industry, the manufacturing of turbine blades, and fulfilling general part radius requirementsTo properly employ a ball nose end mill (with no tilt angle) and gain the optimal tool life and part finish, follow the 2step process below (see Figure 1)Planetary Ball Mills are used wherever the highest degree of fineness is requiredIn addition to wellproven mixing and size reduction processes, these mills also meet all technical requirements for colloidal grinding and provide the energy input necessary for mechanical alloyingThe extremely high centrifugal forces of a planetary ball mill result in very high pulverization energy and Planetary Ball Mill PM 100 RETSCH highest finenessparameter ta and crusher model energy matrices, the SMC Test the ball mill is less energy efficient than a crusher and has to input more energy to do the same amount of size reduction) Hence from equation 7, to crush to the ball mill circuit feed size (x 2USING THE SMC TEST® TO PREDICT COMMINUTION

Parameter Optimization of Ultrafine Comminution Based on

D Fan, Research on the Media Movement Form and Parameters of Ball Mill, Zhejiang University of Technology, Hangzhou, China, 2010 L Chang, W Wang, and H Ru, “Effect of ball milling parameters on the preparing ultrafine WC powders,” Journal of Minerals, Metallurgy and Materials, vol 18, pp 207–212, 2019 View at: Google ScholarDetermination of RTD model parameters is a prerequisite to simulate a grinding circuit which will be explained in more details in Section 24 Breakage distribution functionBreakage distribution function (also known as breakage function and appearance function) is a fundamental parameter of tumbling ball mill (PDF) Spreadsheetbased simulation of closed ball milling New users generally don’t have the experience and don’t know the math so it takes a while to get an intuitive understanding of of the stepover parameter The following post focuses mostly on 3D toolpaths so we’ll be assuming the use of a ball millHow to Choose a Stepover GRZ Software

Vertimill® Outotec

Vertimill® has an excellent turndown ratio and can be operated at lower than installed power with less effect on grind efficiency than for example horizontal ball mills Feed FlowRate This parameter is used in conjunction with the feed density and motor power to establish the grinding rate in kWh/mtThe milling of the materials is a very useful procedure in various domains in life as well as in the constructive domain Click HERE to subscribe to Make itMaking a Ball Mill YouTube40Pcs End Mill Bits Set 1/8" Shank, Mcwdoit Router Bits Cutting Milling Tool Engraving Cutter Including Flat Nose/Ball Nose End Mill, Nano Blue Coat/Titanium Coat 2 Flute Router Bits 45 out of 5 stars 379 Misc $2999 $ 29 99 Get it as soon as Tue, Mar 16 FREE Shipping by AmazonAmazon: Ball Nose End Mills: Industrial Scientific

Overflow Type Ball Mill chinacfccc

Overflow type ball mill is a kind of beneficiation ball mill whose name comes from its ore discharge method The overflow type ball mill is widely used in cement, mineral, refractory material and other industries According to the discharge method, it is also suitable for the beneficiation industry to grind fine ores or regrind concentrates