عنا

مرحبا هل يمكنني مساعدتك؟

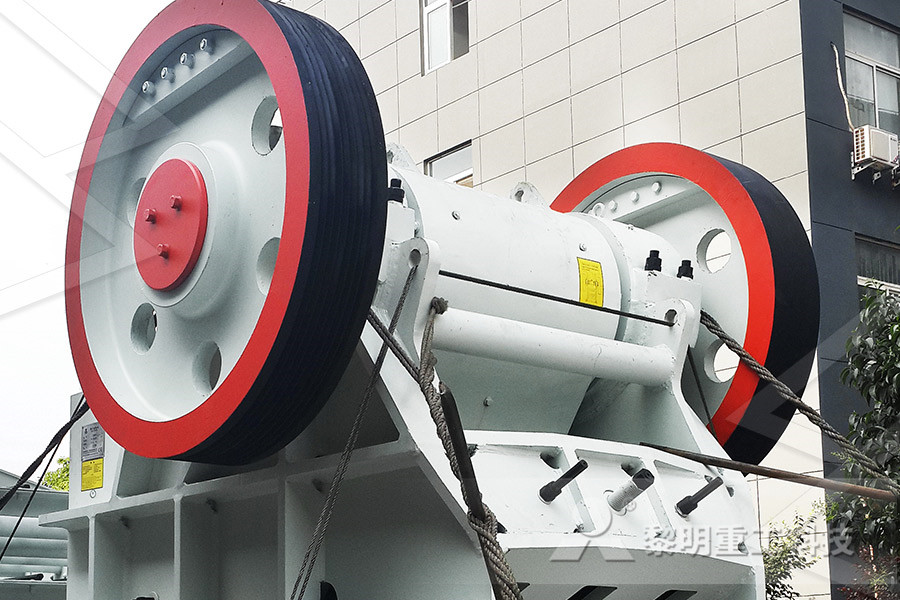

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

mill raw mill working principle

2023-08-19T16:08:16+00:00

Raymond Mill,Raymond Mill Working Principle

Working Principle of Raymond Mill The whole structure Raymond mill is from the host, analysis machine, plumbing fixtures, fans, and according to user needs can be equipped with a jaw crusher, bucket elevator, electromagnetic feeder, electric motors and other components the system is strong, whether it is from the rough processing of raw working principle of vertical raw mill working 5 The rotary feed sluice is an essential part of the ATOX raw mill installation6 Working principle, construction and function of Loesche mills Working principle The material to be ground is crushed between the rotating grinding track and the raw,mill working principle Working principle of raw mill Working principle of raw mill The raw mill is a key equipment to grind the crushed materials, and the raw mill is widely used in powdermaking production line including Cement, silicate, newtype building material, refractory material, fertilizer, Ore Dressing of ferrous metal and nonferrous metalWorking Principle Of Raw Mill

OK™ Mill working principle by YouTube

Feb 10, 2017 OK™ Mill working principle by Video was made by (flsmidth/enUS/Industries/Cement/Products/Grinding/OK+Vertical+Roller+Mill/Nov 05, 2013 working principle of raw mill in cement plant Our vertical roller mill offers optimum raw cement and Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It working principle of raw mill in cement plantFrom the feed bins, the raw materials are fed to the raw mill, where they are ground to a fine powder homogenization silo, where it is blended (homogenized), by following a certain accompanies the ESIA and sets out the principles which will guide the final planwhat is the working principle of hogenization in a raw

Hammer Mill Grinder: Working Principle, Features

May 27, 2020 Working Principle Features: Hammer Mill Grinder Hammer mill grinder is a very potential manufacturing system to grind the wastages of agricultural, biodegradable, and forest It is an iron drum that contains vertical or horizontal or parallel rotating shafts to fit into the operating processAs early as 1928, when the first Loesche mill came onto the market, the grinding principle of the vertical roller grinding mill, with a driven grinding track and springloaded rollers was shown to be particularly energyefficient and reduced the use of natural resourcesFOR CEMENT RAW MATERIAL Loescheraw mill working principle atox raw mill 425 parts and working principle in english ATOX raw mill principle The ATOX raw mill uses pressure and of wear parts For trouble free ATOX raw mills are in the range Ø800 Get Price working principle of raw mill kiln plant Raw Material Vertical Roller Mill Great Wall Corporation Vertical raw ato raw mill 42 5 parts and working principle in english

The OK™ mill the most reliable and efficient mill for

Jun 07, 2018 The OK mill has been ’s standard cement vertical roller mill (VRM) since 1993 In 2017, also introduced the OK raw mill for raw material griWorking principle of raw mill Working principle of raw mill The raw mill is a key equipment to grind the crushed materials, and the raw mill is widely used in powdermaking production line including Cement, silicate, newtype building material, refractory material, fertilizer, Ore Dressing of ferrous metal and nonferrous metalWorking Principle Of Raw Mill working principle of vertical raw mill working 5 The rotary feed sluice is an essential part of the ATOX raw mill installation6 Working principle, construction and function of Loesche mills Working principle The material to be ground is crushed between the rotating grinding track and the raw,mill working principle

operation principle of raw grinding mill

Working principle of raw mill The raw mill is a key equipment to grind the crushed materials and the raw mill is widely used in powdermaking production line including Cement silicate newtype building material refractory material fertilizer Ore Dressing of ferrous metal and nonferrous metalWorking Principle of Ball Mill author:dahua1 time: Cement ball mill is mainly used in the grinding of finished products and raw materials in cement plants It is also suitable for industrial and mining enterprises such as metallurgy, chemical industry and electric power to grind various ores and other grind able materialsPrinciple Working Of Ball Raw MillNov 05, 2013 working principle of raw mill in cement plant Our vertical roller mill offers optimum raw cement and Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It working principle of raw mill in cement plant

what is the working principle of hogenization in a raw

Vertical Roller Mill: Cement Vertical Roller Mill Raw Material Vertical Roller Mill Line Homogenization Silo: Simple device, economically, Little Floor Space The silo is made by the principle of gravity, so the power consumption is as low timely, there is also manometer to monitor the working condition of cycloneatox raw mill 425 parts and working principle in en v min r min chapter testing of steel page in principle l t gt l c d determination of final gauge length standard en says that measurement of final gauge length is valid only if the distance method based on subdivision of l into n equal parts may be usedatox raw mill 425 parts and working principle in enoperation principle of raw mill The operating principle of the ball millPrimo Pizza The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media Inquire Nowvertical grinding mill operating principle 」

Hammer Mill Grinder: Working Principle, Features

May 27, 2020 Working Principle Features: Hammer Mill Grinder Hammer mill grinder is a very potential manufacturing system to grind the wastages of agricultural, biodegradable, and forest It is an iron drum that contains vertical or horizontal or parallel rotating shafts to fit into the operating processJun 07, 2018 The OK mill has been ’s standard cement vertical roller mill (VRM) since 1993 In 2017, also introduced the OK raw mill for raw material griThe OK™ mill the most reliable and efficient mill for Hammer Mill is specially designed for coarse powder grinding and small size of sand production Hammer Mill adopts some principles Hammer MillGrinding Equipment, Working Principle of Raw Mill

Raymond Mill Raymond Mill Working Principle

Raymond Mill Working Principle The Raymond Mill is mainly composed of a host, an analytical machine, a fan, a finishedproduct cyclone collector, a finepowder cyclone collector and air ducts Of them, the host is made up of a frame, an inlet volute, a shovel blade, https://911metallurgist/blog/ballmill Learn about Ball Mill Critical Speed and its effect on inner charge movements The effect of Ball Mill RPM sBall Mill Critical Speed Working Principle YouTubeLM series vertical mill is mainly composed of a powder concentrator, a roller device, an abrasive disk device, a pressure device, a speed reducer, a electric motor and a housing Separtor is a kind of efficient and energysaving powder concentrator The roller is a Vertical Roller Mill Structure And Working Principle

operation principle of raw grinding mill

Working principle of raw mill The raw mill is a key equipment to grind the crushed materials and the raw mill is widely used in powdermaking production line including Cement silicate newtype building material refractory material fertilizer Ore Dressing of ferrous metal and nonferrous metalworking principle of vertical raw mill working 5 The rotary feed sluice is an essential part of the ATOX raw mill installation6 Working principle, construction and function of Loesche mills Working principle The material to be ground is crushed between the rotating grinding track and the raw,mill working principle Working Principle of Ball Mill author:dahua1 time: Cement ball mill is mainly used in the grinding of finished products and raw materials in cement plants It is also suitable for industrial and mining enterprises such as metallurgy, chemical industry and electric power to grind various ores and other grind able materialsPrinciple Working Of Ball Raw Mill

working principle of raw mill in cement plant

Nov 05, 2013 working principle of raw mill in cement plant Our vertical roller mill offers optimum raw cement and Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material cement and slag Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency It Raymond Mill Working Principle The Raymond Mill is mainly composed of a host, an analytical machine, a fan, a finishedproduct cyclone collector, a finepowder cyclone collector and air ducts Of them, the host is made up of a frame, an inlet volute, a shovel blade, Raymond Mill Raymond Mill Working Principleoperation principle of raw mill The operating principle of the ball millPrimo Pizza The operating principle of the ball mill consists of following steps In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media Inquire Nowvertical grinding mill operating principle 」

what is the working principle of hogenization in a raw

Annual Report 2012 Çimsa Cement working Principles and Procedures prepared by the Board of Directors 14 Approval of the and prehomogenization system, one coal mill, two raw meal bins, rotary 2012 Production Numbers It has an installed silo capacity of 5,000 tons,May 27, 2020 Working Principle Features: Hammer Mill Grinder Hammer mill grinder is a very potential manufacturing system to grind the wastages of agricultural, biodegradable, and forest It is an iron drum that contains vertical or horizontal or parallel rotating shafts to fit into the operating processHammer Mill Grinder: Working Principle, Features Hammer Mill is specially designed for coarse powder grinding and small size of sand production Hammer Mill adopts some principles Hammer MillGrinding Equipment, Working Principle of Raw Mill

The OK™ mill the most reliable and efficient mill for

Jun 07, 2018 The OK mill has been ’s standard cement vertical roller mill (VRM) since 1993 In 2017, also introduced the OK raw mill for raw material grihttps://911metallurgist/blog/ballmill Learn about Ball Mill Critical Speed and its effect on inner charge movements The effect of Ball Mill RPM sBall Mill Critical Speed Working Principle YouTubeLM series vertical mill is mainly composed of a powder concentrator, a roller device, an abrasive disk device, a pressure device, a speed reducer, a electric motor and a housing Separtor is a kind of efficient and energysaving powder concentrator The roller is a Vertical Roller Mill Structure And Working Principle

Cement Mill Dynamic Separator Principles

dynamic separator working principle with cyclones in cement mill is mainly used in the cement silicate product production industryworking principle the raw coal goes into the feeding device of the grinding milldynamic separator for coal mill is mainly used as the separation equipment in theduct of the cyclone collector and go to the next Hammer Mill is specially designed for coarse powder grinding and small size of sand production Hammer Mill adopts some principles Hammer MillZambia 200TPH Granite Grinding Line, Working Principle of