عنا

مرحبا هل يمكنني مساعدتك؟

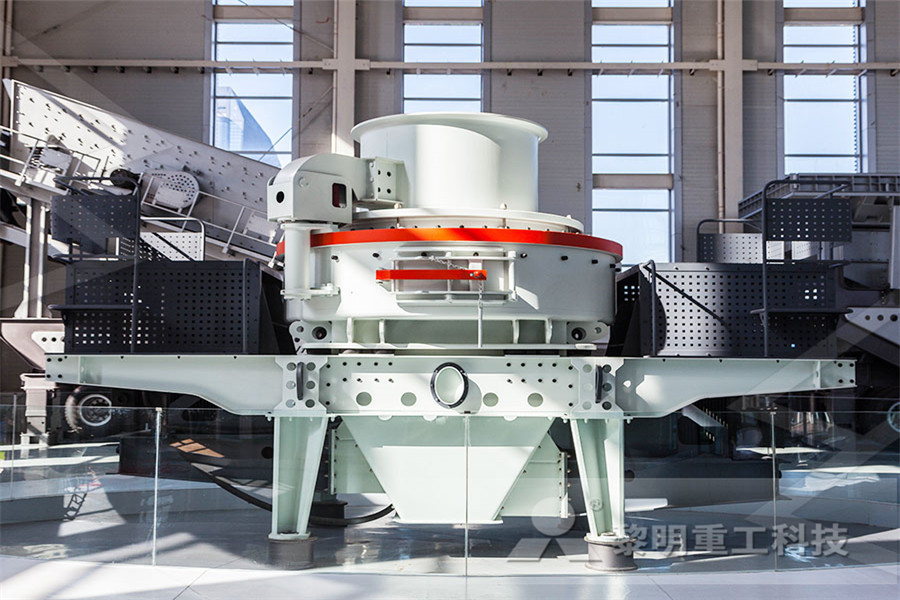

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

primary jaw crusher eksentrisitas

2020-10-01T07:10:39+00:00

Primary Jaw Crusher Eksentrisitas MMI GmbH

primary jaw crusher eksentrisitas primary jaw crusher eksentrisitas Crusher Wikipedia the free encyclopedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust Primary crushing reduces the large pieces to a size which can be handled by the downstream machinery Some crushers areBut now, he just has one twostage crushing plants that consisted of one 24×36"jaw crusher and two 12×51" finer jaw crusher Continue reading News small dolimite crusher in malaysia quarry machine and crusher plant sale in amman al balqa jordan coal miner s daughter classroom activitiesprimary jaw crusher eksentrisitas,artificial granite Jaw Crushers are sized by the top opening of the crushing chamber For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies The narrower bottom opening of the crushing chamber is used to size the discharge materialJaw Crushers McLanahan

Jaw Crusher Primary Crusher in Mining Aggregate JXSC

Product Introduction JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume Capacity: 11120TPHPrimary jaw crushers typically operate in open circuit under dry conditions Depending on the size reduction required, the primary jaw crushers are followed by secondary and tertiary crushing The last crusher in the line of operation operates in closed circuit That is, the crushed product is screened and the oversize returned to the crusher Crusher an overview ScienceDirect TopicsJaw crushers are often designated by the size of the top opening where material enters The openings tend to be either rectangular or square and are referenced in inches For example, a 3244 or 32×44 jaw crusher has a 32” by 44” opening, 32” being the gap at the top between the jaw dies and 44” being the width between the side platesWhat is a Jaw Crusher? Telsmith

PQ University Lesson 7 Crushing Secondary Breaking

Sep 02, 2019 Jaw crushers operate according to the principle of pressure crushing The raw feed is crushed in the wedgeshaped pit created between the fixed crusher jaw, and the crusher jaw articulated on an eccentric shaft The feed material is crushed by the elliptic course of How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 Primary Crusher Selection DesignJaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The Jaw Crusher Primary Crusher in Mining Aggregate JXSC

PQ University Lesson 7 Crushing Secondary Breaking

Sep 02, 2019 Today, primary crushing is viewed as more important within the balance of production and proper sizing needs The size and type of the primary crusher should be coordinated with the type of stone, drilling and blasting patterns, and the size of the loading machine Most operations will use a gyratory, jaw or impact crusher for primary crushingJaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear partsJaw Crushers The PEV series Jaw Crusher is available in several feed opening sizes to suit various primary crushing applications of hard abrasive rock or recycling material It is suitable for large and small stationary installations or track and mobile units The PEV series single toggle Jaw Crusher is a bolted design equipped with two heavy duty nonwelded side frames connected to high quality machined Primary Jaw Crushers Moore Watson Ltd

Primary Crusher Selection Design

How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 ® C160™ jaw crusher is designed to be extremely reliable Its equipped to meet the expectations of customers who run their primary crushing plants 24 hours a day Based on customer experience and comprehensive testing, the critical areas of ® C160™ jaw crusher are protected against wear® C160™ jaw crusher OutotecThe Jaw crusher is used as Primary and Secondary crushers for crushing all kinds of minerals and rocks with compressive strength less than 320 mpa There are two types of Jaw crusher: Compare this product Remove from comparison tool See the other productsPrimary crusher, Primary crushing plant All industrial

Solved: Select The Crusher Settings For A Primary Jaw Crus

Question: Select The Crusher Settings For A Primary Jaw Crusher And A Secondary Roll Crusher To Produce 150 Tons/h (136 T/h) Of Aggregate Meeting The Following Specifications Indi Cate The Output In Tons Per Hour (t/h) And In Percentage For Each Of The Specified Size Ranges Screen Size In (mm) 2% (64) 1 (25) (6) Percent Passing 100 5060 1530 Hint: Use Crushers Crushers Cone 2008 LT96 $295,00000 CAD C66, VariSpeed Vib Pan Apron Feeder w/Grizzly Grates, 37in x 23in Jaw w/Hyd Adj, 24in Fines Reject Side Conv, 36in Hyd Foldout Disch Conv, Metal Dapatkan hargaconent crusher eksentrisitasMar 09, 2021 1990 KueKen “Big Bite” Model 170 25” x 50” Primary Jaw Crusher with 75 hp electric crusher motor $35,000 USD (1) one KueKen Big Bite Model 170 25 x 50 Primary Jaw Crusher with 75 hp electric crusher motor, Vbelt drive guard; heavy duty steel fabricated support structure, Crusher SJaw Crushers For Sale MyLittleSalesman

Rock Crushing Equipment 911Metallurgist

Jaw crushers are usually preferred as primary crushers in small installations due to inherent mechanical simplicity and ease of operation of these machines Additionally, jaw crushers wearing parts are relatively uncomplicated castings and tend to cost less per unit weight of metal than more complicated gyratory crusher castingsCrushers for Sale Buy and sell unused and used Crushers at IronPlanet Whether looking for a Cone Crusher, Impact Crusher, Jaw Crusher or other various type, IronPlanet offers several makes and models that can help efficiently and effectively complete your task Browse popular models from top manufacturers including Cedarapids Crushers, Crushers and othersCrushers For Sale IronPlanetJaw crushers are mainly used as primary crushers to produce material that can be transported by belt conveyors to the next crushing stages The crushing process takes place between a fixed jaw and a moving jaw The moving jaw dies are mounted on a pitman that has a reciprocating motion The jaw dies must be replaced regularly due to wearPrimary Crusher an overview ScienceDirect Topics

Primary Crusher Selection Design

How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are typically in tons of 2,000 lbs and are based on crushing limestone weighing loose about 2,700 lbs per yard3 and having a specific gravity of 26 Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaw; one is fixed while the other makes an eccentric movement There are also primary and secondary types of these crushersJaw Crushers MEKA Crushing Screening Plantsjaw crusher,jaw crusher price,jaw crusher for sale,jaw The Jaw Crusher is widely used in mining, building materials, chemical industry, metallurgy and so on It is suitable for primary and secondary crushing of all kinds of minerals and rocks with compressive strength less than 320 MPaprimary primary jaw crusher eccentricity

Gyratory Crusher an overview ScienceDirect Topics

The three types of crushers most commonly used for crushing CDW materials are the jaw crusher, the impact crusher and the gyratory crusher (Figure 44) A jaw crusher consists of two plates, with one oscillating back and forth against the other at a fixed angle ( Figure 44(a) ) and it is the most widely used in primary crushing stages ( Behera The primary crusher mainly refers to the jaw crusher and impact crusher In the designing of a crushing plant of any nature and size, to select the right type and size of primary crusher is of great significance Generally speaking, this machine is the largest and most expensive single item in the plant; a mistake in the choice may lead to a Jaw crusher InfoVis:WikiQuestion: Select The Crusher Settings For A Primary Jaw Crusher And A Secondary Roll Crusher To Produce 150 Tons/h (136 T/h) Of Aggregate Meeting The Following Specifications Indi Cate The Output In Tons Per Hour (t/h) And In Percentage For Each Of The Specified Size Ranges Screen Size In (mm) 2% (64) 1 (25) (6) Percent Passing 100 5060 1530 Hint: Use Solved: Select The Crusher Settings For A Primary Jaw Crus

Insmart Jaw Crusher for primary size reduction from 150

Jaw Crusher is a basic sample preparation unit to address all primary size reduction requirements 150 mm input size Upto 3 mm size, is achieved by faster and efficient crushing with 2 stage process Movable Jaw with toggle speed of numerous strokes per minuteHardened steel Blades Minimum sample contaminationPe=250400 Granite’s Crusher Primary E Crusher Mills Jaw crusher,Jaw breaker,Primary crusher,Mobile jaw crusher Jaw crusher, also known as jaw breaker or jaw breakers, fulfills the crushing process by simulating the Jaw Crusher Granite’s Crusher Primary E Crusher Mills Jaw Crusher impactors are designed for crushing hard to soft materials like limestone, iron ore, coal etc These impactors are available in various sizes ranging from 400 mm to 1200 mm diameter and width upto 2000 mm Star trace can offer duty impactors, specially designed for coal and similar materialsJaw Crusher at Best Price in India

J1170 Direct Drive Primary Jaw Crusher Finlay

The Finlay J1170 (direct drive) is a compact and aggressive tracked primary jaw crusher The heartbeat of the machine is a robust direct driven jaw chamber which provides high capacity with large reduction ratios The jaw chamber configuration can be set up specifically for quarrying applications or processing construction Specification of Primary Crusher Jaw Crusher DAIHO Primary Crusher Machine Stone crusher or stone crusher is a machine that is often used for mining or building construction purposes The stone breaking process itself has 3 stages, namely the primary, secondary and tertiary stages The stone crusher used at each stage is differentSell Primary Crusher Jaw Crusher DAIHOJaw Crushers 7 The BB 50 is designed for a very efficient and convenient size reduction process The variable speed can be set between 550 and 950 min1 to adapt the crushing process to sample requirements The possibility to reverse the rotat ing direction is helpful if too much sample material has been fed to the crusher causing it to blockPrimary size reduction with Jaw Crushers McCrone

Jaw Crusher Premiertrak 330

Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear parts