عنا

مرحبا هل يمكنني مساعدتك؟

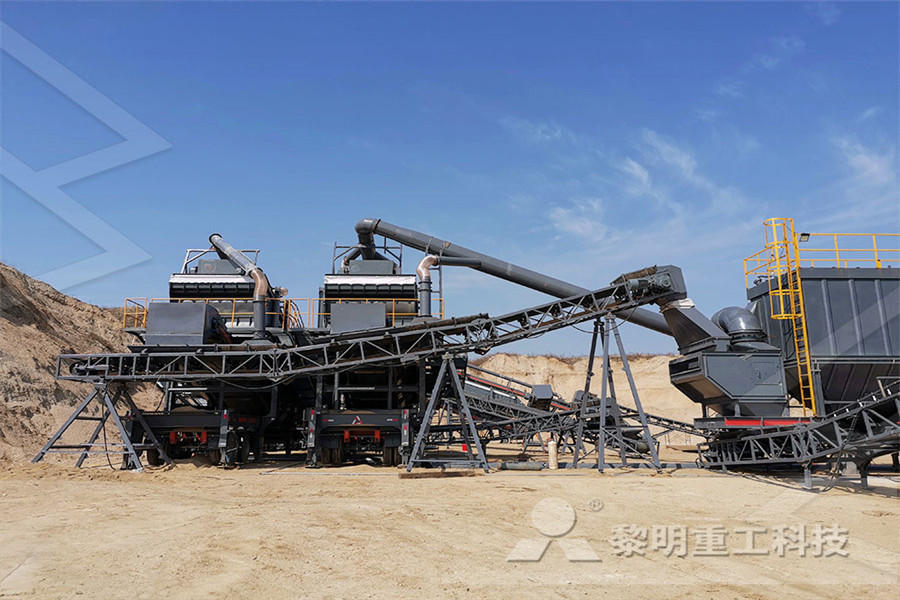

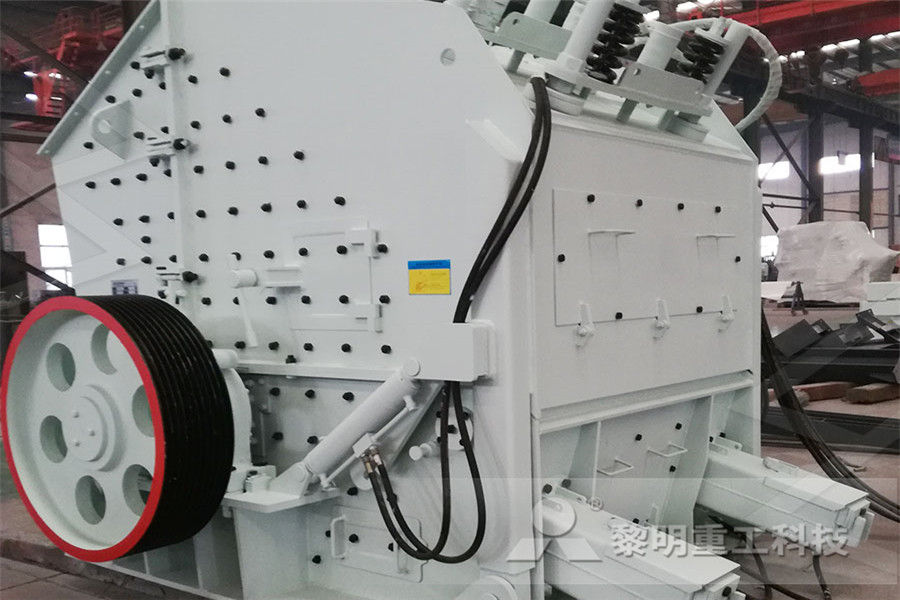

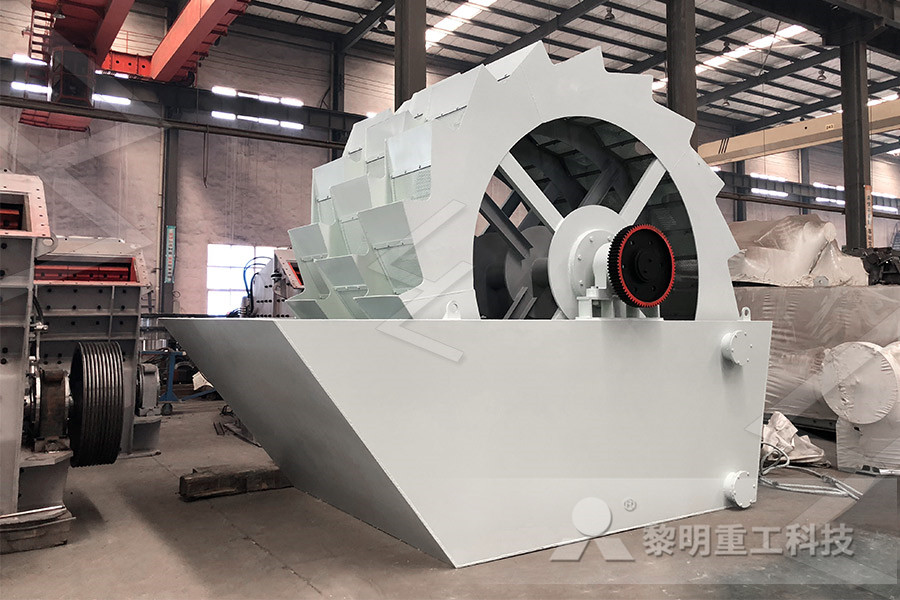

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

gravity ncentration mining

2018-12-31T16:12:03+00:00

Advantages Of Using Gravity Concentration For Gold Recovery

The Benefits of Gravity Concentration In Gold Mining Low CAPEX and OPEX Costs Gravity concentration has a lower overall cost per ounce produced compared to cyanide leaching Low Circuit Lockup Other things being equal, the faster you For decades, Knelson gravity concentrators have been the gold standard for recovery of gold and precious metals ’s latest innovation in semicontinuous gravity separation is the newGravity concentration breakthrough improves Gravity concentration is at present the main concentration process in the mineral industry in terms of tons processed The size that can be processed ranges from very coarse materials, coarser than 100 mm, concentrated through heavy media vessels or ROM jigs, to very fine particles, about 10 microns, concentrated through centrifugal processesMinerals Special Issue : Gravity Concentration

Multi Gravity Separator Gravity Mining

Welcome to Gravity Mining Ltd The home of the original Richard Mozley Multi Gravity Separator (MGS); a machine that is unsurpassed when it comes to fine mineral gravity concentrationGold, due to its increasing value, is the main mineral extracted by at least half of these miners The large majority use amalgamation either as the final process to extract gold from gravity concentrates or Gravity Concentration in Artisanal Gold MiningFor decades, Knelson Gravity Concentrators have been recognised for industrybest recovery of gold and precious metals The latest innovation in semicontinuous gravity separation is the new Knelson GX Concentrating Cone, which delivers a key breakthrough in performance that increases recovery and cuts maintenance downtime develops gravity concentration techonlogy

Multi Gravity Separator Gravity Mining

Gravity Mining manufactures the Richard Mozley Multi Gravity Separator (MGS) often called an Enhanced Gravity Separator (EGC) or Centrifugal Concentrator Gravity Mining provides mineral testing, process plant design, manufacture of MGS, pumps to mining Gravity separation: a mineral processing technique Gravity separation, also known as gravity concentration in mineral processing, is a technique of separating valuable minerals from gangue, based on their specific weight differences It is applied using water, particular liquids, or even airGravity Separation Principle, Uses and Applications The Gekko plant is ideally suited to processing Kat Gap ore, which has a unique high gravity gold concentration Classic will have the capability and capacity to commence production as soon as the mining approvals (MLA 74/249) have been granted”gravity concentration Archives International Mining

The myth of gravity concentration to eliminate mercury use

Ultimately, this article concludes that gravity concentration is not the final solution to eliminate mercury use in artisanal gold mining, but it can drastically reduce the use of In 1976, Benjamin Virgil (Byron) Knelson changed the face of the gravity concentration industry to what mining professionals know it as today This was the year the the first Knelson Concentrator was tested and Knelson Concentrators, now owned by , has pioneered and led gravity concentration technology ever sinceGCA Mineral Concentration SpecialistsWikiProject Mining may be able to help recruit an expert (March 2008) A Knelson concentrator is a type of gravity concentration apparatus, predominantly used in the gold mining industry It is used for the recovery of fine particles of free gold, meaning gold Knelson concentrator Wikipedia

GRAVITY CONCENTRATION OF GOLD FROM CYCLONE

Where there is gravity recoverable gold, it is important that it be maximized, as the unit operating cost for a gravity circuit is much lower than that for any other process Minimizing the Size of the Gravity Concentration Circuit Many process engineers view gravity concentration in gold grinding circuits as a nuisance and a security riskEnhanced Gravity Concentration for Small Scale and Artisanal Miners No Mercury No Cyanide iCON uses classification and enhanced gravity in its centrifugal concentrators to ensure that you are recovering the most gold possible iCON uses the same proven technology as the Falcon brand of professional mining products: it was designed by Gold Recovery, iCON Gold Recovery, Gravity Concentrators When the water flow is 50 L/min, the concentrate is 10056 g / t, and the recovery rate is 6435% 【223 Enrichment time】 Experimental conditions: pulp density 30%, ore feeding speed 1 kg/min, gravity value is 40G, fluidization water 50 L/ min, enrichment time Knelson Concentrator Gravity Separation of JXSC Mining

So what exactly is 'gravity concentration?' Gravity Rush 2

The main point of the mining sites, as others have stated, is getting talismans of varying grades and skillenhancing abilities At some point in the campaign, one gets the ability to merge them into a selection of skills you want (up to 3 so decreasing damage gravity gauge usage upping attackrange as an option, or drastically expanding GRAVITY CONCENTRATION Gravity concentration processes rely on the principal that gold contained within an ore body is higher in specific gravity than the host rocks that contain the gold Elemental gold has a specific gravity of 193, and typical ore has a specific gravity of about 26 All gravity concentration devicesGold Mining Process Development – Denver Mineral EngineersNov 21, 2018 The best practices for chemical leaching are a combination of preconcentration and mill leaching, as they lead to the least amount of waste, a short processing time for miners, and high gold recoveries First, concentration is done through gravity techniques Then the concentrate is simultaneously milled and leachedArtisanal and SmallScale Gold Mining Without Mercury

Tailings Wikipedia

Tailings are the materials left over after the process of separating the valuable fraction from the uneconomic fraction of an oreTailings are distinct from overburden, which is the waste rock or other material that overlies an ore or mineral body and is displaced during mining without being processed The extraction of minerals from ore can be done two ways: placer mining, which uses water "Gravity concentration is the separation of minerals based on differences in specific gravity A gravity concentration process is designed to recover very high grades of valuable ore material into very small masses The resurgence of gravity concentration in mining has come about due to its simplicity and low environmental impactIPJ Plant TARANIS RESOURCES INCAn Introduction to Gravity Concentration Gravity concentration is the separating of particles by their relative densities (specific gravity) Gravity concentrating has been used to process minerals for a long time, Agricola in De Re Metallic (1556) reported the use of gravity concentrating (jigging) by the Egyptians around 1000BC (3000 years ago)Gravity Concentrating in Mineral Processing

IPJ Plant TARANIS RESOURCES INC

"Gravity concentration is the separation of minerals based on differences in specific gravity A gravity concentration process is designed to recover very high grades of valuable ore material into very small masses The resurgence of gravity concentration in mining has come about due to its simplicity and low environmental impactAug 14, 2018 Mineral jigs are a type of mining equipment, also referred to as gravity concentrators or jig concentrators, that are used in operations to separate different ore materials based on Mineral Jig Concentrators for Ore Processing Separation Gravity Concentration — the separation of minerals by virtue of specific gravity — is one of the oldest forms of mineral processing Whilst its relative importance has declined in the twentieth century, the high cost of alternative processes, along with the development of a range of high capacity devices has led to something of a Gravity Concentration Methods SpringerLink

GRAVITY CONCENTRATION OF GOLD FROM CYCLONE

Where there is gravity recoverable gold, it is important that it be maximized, as the unit operating cost for a gravity circuit is much lower than that for any other process Minimizing the Size of the Gravity Concentration Circuit Many process engineers view gravity concentration in gold grinding circuits as a nuisance and a security riskGRAVITY CONCENTRATION Gravity concentration processes rely on the principal that gold contained within an ore body is higher in specific gravity than the host rocks that contain the gold Elemental gold has a specific gravity of 193, and typical ore has a specific gravity of about 26 All gravity concentration devicesGold Mining Process Development – Denver Mineral EngineersNov 21, 2018 The best practices for chemical leaching are a combination of preconcentration and mill leaching, as they lead to the least amount of waste, a short processing time for miners, and high gold recoveries First, concentration is done through gravity techniques Then the concentrate is simultaneously milled and leachedArtisanal and SmallScale Gold Mining Without Mercury

Knelson Concentrator Gravity Separation of JXSC Mining

When the water flow is 50 L/min, the concentrate is 10056 g / t, and the recovery rate is 6435% 【223 Enrichment time】 Experimental conditions: pulp density 30%, ore feeding speed 1 kg/min, gravity value is 40G, fluidization water 50 L/ min, enrichment time Jan 24, 2017 Mining ore yields bright pink gems referred to as Precious Gems, Each of these will be marked with a Gravity Concentration, Minable Volume, and Current Mining ‘Gravity Rush 2’ Mining Is Necessary InverseThe gravity concentration of the mining location hosting the Gravity Storm may affect the number of Nevi spawning in the Trench Mine Rare Nevi , green variations of standard Nevi that have significantly greater health and damage output than their counterparts, can be randomly encountered from mining ore at any gravity concentration even when Delvool Trench Mine Gravity Rush Wiki Fandom

breaks ground with gravity concentration

breaks ground with gravity concentration February 15, Deloitte’s top 10 trends for 2021 have highlighted the mining sector’s commitment to continual improvement and in laying a To determine the fullscale recoveries of a potential mining operation, benchscale gravity concentration testing is a crucial mineral beneficiation process For the most accurate results, MetSolve uses a variety of mineral processing equipment like spirals, shaking tables, and analytical tables, but our specialty lies in centrifugal gravity concentration technology Our Gravity Concentrators Using Gravity Concentration To Test For Minerals Sepro Labsfurther gravity concentration The final gravity concentrate often needs cleaning by magnetic separation, leaching, or some other method, in order to remove other mineral contaminants For instance, at the South Crofty tin mine in Cornwall, the gravity concentrate was subjected to Gravity concentration Webs

Gravity concentration Yantai Jinpeng Mining equipment

Gravity concentration; JinPeng Mining has very strict production management and advanced production technology, and has achieved ISO 9001: 2008 We own various kinds of devices such as: automatic cutting machine, automatic welding machine, 5 meters vertical lathe, lathe, boring machine, and the largest lathe in Shandong