عنا

مرحبا هل يمكنني مساعدتك؟

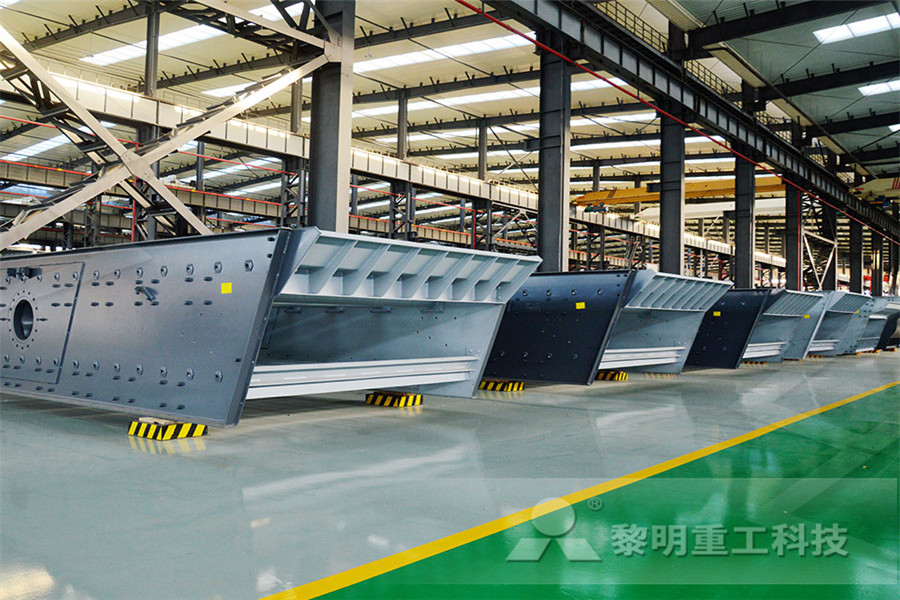

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

iron ore processin plant

2020-05-23T13:05:30+00:00

Iron Ore Processing Plants Iron Ore Wash Plants CDE

Our iron ore wet processing plants are proven to successfully deal with silica and alumina contamination in the iron ore, resulting in an increase in the Fe value of the iron ore thereby increasing the efficiency of the steel production processThis is where the processing plant of Scandinavia’s biggest iron ore producer is located, with a facility for direct loading of iron ore pellets onto ships The existing plant has a processing rate of 6,000 t/h, and a new plant with a processing rate of an additional 9,000 t/h had to be addedIron Ore Processing HomeThe current iron ores beneficiation plant generally through the crusher crushed the raw ore, and then into the ball mill smashed through the gravity separation, flotation, extracted from the concentrate and tailings, and through chemical methods, and iron ore beneficiation products Iron Ore Processing Plant Shanghai Company

Iron Ore Processing Plant Iron Ore Processing Plant

We offer turnkey solutions for iron ore processing plants Fabricated from highest quality raw materials, these plants are provided with Feed Hopper, Ball Mill for grinding, Wash drum (Scrubber), Spiral Classifier bank, Hydro cyclones bank, Multideck Rectangle Vibratory Screens, Low; Medium highIntensity Magnetic Separators, and Tailing PondKnowing that not all clients are the same and that all applications differ was the driving force behind the MAX Plant range of equipment From the beginning the team at MAX Plant looked at innovation as the driving force and how the portability can make a difference to the capital costs of setting up a mineral processing plant, whether in a mining application or a quarry application the MAX MAX Plant Iron Ore Processing ProjectsWe are indulged in providing specialized Iron Ore Processing Plant Fabricated from highest quality raw materials, these machines are provided with Feed Hopper, Ball Mill for grinding, Wash drum (Scrubber), Spiral Classifier bank, Hydrocyclones bank, Mineral Processing Plants Iron Ore Processing Plant

MAX Plant Iron Ore Processing Projects

Knowing that not all clients are the same and that all applications differ was the driving force behind the MAX Plant range of equipment From the beginning the team at MAX Plant looked at innovation as the driving force and how the portability can make a difference to the capital costs of setting up a mineral processing plantFeb 20, 2021 NORILSK, Russia A building at an iron ore processing plant in Russia's Arctic city of Norilsk has collapsed, killing at least two workers The regional branch of the Emergencies Ministry said Two Workers Killed After Collapse At Mineral Processing Jun 20, 2016 Pilbara Iron Ore Processing Plant 25Mtpa iron ore plant complete with crushing, screening, fines lump stacking and reclaim systems, and train loadout faciPilbara Iron Ore Processing Plant YouTube

Prairie River Minerals Building Iron Range Plant

Apr 14, 2020 Prairie River Minerals Building Iron Range Plant Construction is expected to start this month on a multimillion dollar ore processing plant on the Iron Range By Koodaideri will deliver a new production hub for Rio Tinto’s worldclass iron ore business in the Pilbara, incorporating a processing plant and infrastructure including a 166kilometre rail line connecting the mine to the existing network Construction will start next year with first production expected in late 2021Rio Tinto approves $26 billion Rio Tinto Rio TintoMay 26, 2016 As iron ore must be composed of grades of at least 58 per cent, mining companies stack the lower grade material on tailings dumps Dry processing plants also New dry iron ore processing technology developed

Processing plant Roy Hill

Processing plant The processing plant consists of six individual scrubbing, screening and desanding circuits The wet scrubbing units are used to break down the sticky clays attached to the ore, into a fine suspended clay fraction suitable for subsequent wet beneficiation Beneficiation is the process of separating the valuable material from theKGHM KGHM Polska Miedź is one of the largest producers of copper and silver in the world The mining metallurgy company is based in Poland in Lubin KGHM Polska Miedź SA owns shares in 33 entities, operating in various production and servicerelated areas Their vision is to become a major global copper producer by increasing copper production to approximately 700,000 tonnes, and to Mining and Processing PlantsIron Ore Wet Processing Plants Future of Mining CDE CDE Global May 14, 2018 CDE will be exhibiting at the Future of Mining on 14th 15th May in SMC, Syndey, Australiairon ore processing plant in australian mines

Iron processing Britannica

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the We have developed a deserved reputation for the design and delivery of iron ore beneficiation plants, where we have set new benchmarks in cost effectiveness Our principles of innovation and challenging established paradigms are being practiced through our team of expert engineers, with major benefits in cost savings compared to traditional Iron Ore Mining, Processing Engineering AusencoBased on the iron ore processing experience and necessary processing tests, Prominer can supply complete processing plant combined with various processing technologies, such as gravity separation, magnetic separation, flotation, etc, to improve the grade of TFe of the concentrate and get the best yieldIron Ore Processing,Crushing,Grinding Plant Machine Desgin

How much does an iron ore smelting plant cost? Quora

Hello user According to your Question it is totally depend upon your requirements , A Lead Smelting plant cost can be differ with client to client We are listed to be one of the noteworthy names for this impeccable selection of Lead Smelting PlanProcess Of Iron Ore Processing Plant Screening: The first one is screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage Crushing and stockpiling: This step involves breaking up the iron ore to obtain an F80 grind size before it can be ground Once the ore is crush, it is diverted to a stockpile and then fed into the millIron Ore Processing Plant Iron Ore Processing Plant Iron Ore Processing Plant Iron is found in the world's oldest and most widely used, is the largest amount metal, the metal consumption of about 95% of total consumptionIron ore is mainly used for iron and steel industry, smelting iron and steel according tothe different carbon contentThe socalled iron ore deposits is the main target of Iron Ore Processing Plant Shanghai Company

Taconite Iron Ore Processing: National Emission Standards

A taconite iron ore processing facility separates and concentrates iron ore from taconite, a lowgrade iron ore, and produces taconite pellets, which are approximately 60 percent iron and about ½ inch in diameter These pellets are then utilized, mainly, in blast furnaces making iron and steel and in the cement industry Rule HistoryApr 14, 2020 Prairie River Minerals Building Iron Range Plant Construction is expected to start this month on a multimillion dollar ore processing plant on the Iron Range By Prairie River Minerals Building Iron Range Plant 3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~0074 mm) going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationIron Ore Processing Plant Xinhai

MAX Plant Iron Ore Processing Projects

Knowing that not all clients are the same and that all applications differ was the driving force behind the MAX Plant range of equipment From the beginning the team at MAX Plant looked at innovation as the driving force and how the portability can make a difference to the capital costs of setting up a mineral processing plant, whether in a mining application or a quarry application the MAX Mar 15, 2018 The term processing and recovery plant is broad to say the least so we are going to give some basic examples of the types of ore processing plants It is The Basics of How Ore Processing and Recovery Plants Work Koodaideri will deliver a new production hub for Rio Tinto’s worldclass iron ore business in the Pilbara, incorporating a processing plant and infrastructure including a 166kilometre rail line connecting the mine to the existing network Construction will start next year with first production expected in late 2021Rio Tinto approves $26 billion Rio Tinto Rio Tinto

Processing plant Roy Hill

Processing plant The processing plant consists of six individual scrubbing, screening and desanding circuits The wet scrubbing units are used to break down the sticky clays attached to the ore, into a fine suspended clay fraction suitable for subsequent wet beneficiation Beneficiation is the process of separating the valuable material from theKGHM KGHM Polska Miedź is one of the largest producers of copper and silver in the world The mining metallurgy company is based in Poland in Lubin KGHM Polska Miedź SA owns shares in 33 entities, operating in various production and servicerelated areas Their vision is to become a major global copper producer by increasing copper production to approximately 700,000 tonnes, and to Mining and Processing PlantsMay 26, 2016 As iron ore must be composed of grades of at least 58 per cent, mining companies stack the lower grade material on tailings dumps Dry processing plants also New dry iron ore processing technology developed

China Iron Ore Processing Plant, Iron Ore Processing Plant

China Iron Ore Processing Plant manufacturers Select 2021 high quality Iron Ore Processing Plant products in best price from certified Chinese Mining Equipment manufacturers, Mining Machine suppliers, wholesalers and factory on MadeinChinaJul 10, 2017 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter shows the status of the pelletizing process Iron Ore Pelletizing Process: An Overview IntechOpen3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~0074 mm) going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationextraction of iron, process of iron, iron processing, iron