عنا

مرحبا هل يمكنني مساعدتك؟

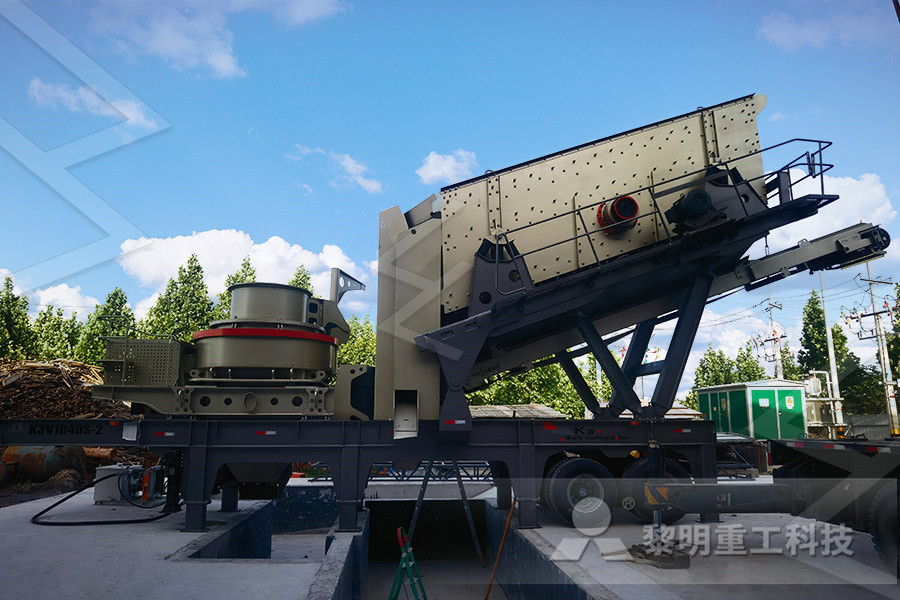

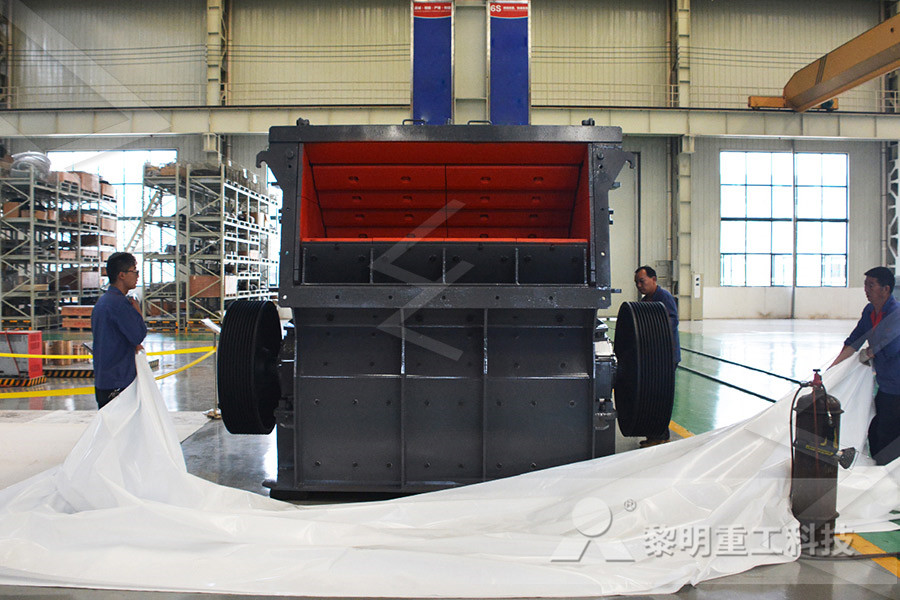

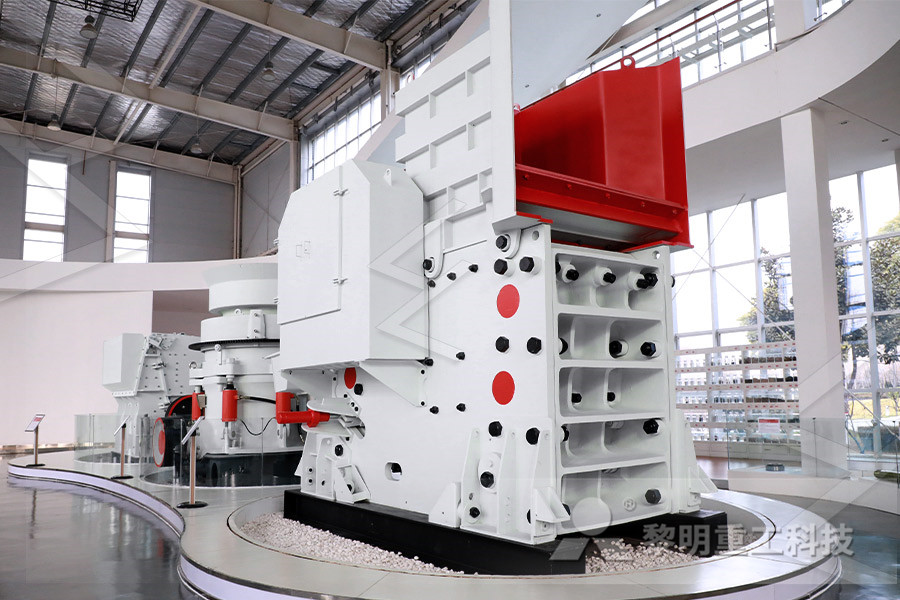

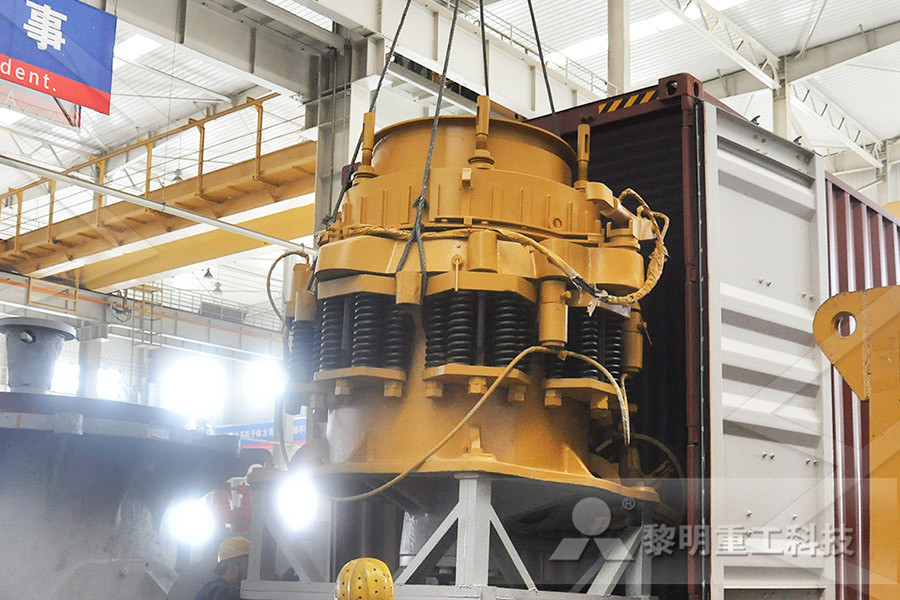

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

Clinker Mill Plant Design

2021-01-05T17:01:15+00:00

clinker mill plant design

Torre Smitherman LinkedIn Plant layout leader for new 3000 STPD Clinker line Included plant layout and design coordination of raw material feed system, raw mill system (roller mill withVertical Roller Mill is a new type of grinding mill based on years concentrated design and development by introducing advanced European technology The proceVertical Mill for Cement Plant, Clinker Grinding YouTubeclinker production of the Adana Cimento plant This project was subsidised by the European Development Bank The sewage sludge had to be dried to a maximum moisture content of 15 % in the waste water Design of a new Pyrosystem and raw mill filter PROFESSIONAL CEMENT PLANT OPTIMIZATION,

Vertical cement mill cement plant,ball mill,vertical

It is widely used in clinker grinding production of cement plant and slag grinding plant CHAENG can provide various types of vertical cement mills with productivity of 50250t/h The biggest advantage of CHAENG is to have a large casting base and large machining workshops, which greatly shortens the delivery cycle of cement vertical millYears of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needsVertical Roller Mills Clinker Grinding Unit, Grinding unit manufacturer, ball mill for Our Cement Clinker Grinding unit can be obtained from 50 TPD to 1000 Cement clinker grinding unit design by the Clinker grinding plant is the last Clinker Grinding Plant Layout 200 Tpd

Clinker Grinding Unit Manufacturers Suppliers in India

We provide high performing Clinker Grinding Plant that is ideal for the efficient grinding of the clinker to produce cement Our Cement Clinker Grinding Plant is comprised of Precrusher, feed hopper, Table feeders, Material Handling equipment, Ball mill, Blending and Packing Plant Our Cement Clinker Grinding Plant is availableclinker production of the Adana Cimento plant This project was subsidised by the European Development Bank The sewage sludge had to be dried to a maximum moisture content of 15 % in the waste water Design of a new Pyrosystem and raw mill filter PROFESSIONAL CEMENT PLANT OPTIMIZATION, We provide high performing Clinker Grinding Plant that is ideal for the efficient grinding of the clinker to produce cement Our Cement Clinker Grinding Plant is comprised of Precrusher, feed hopper, Table feeders, Material Handling equipment, Ball mill, Blending and Packing Plant Our Cement Clinker Grinding Plant is availableClinker Grinding Unit at Best Price in India

Cement mill Wikipedia

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsSmall Cement Clinker Grinding Mill Complete Plant application in mine industry, cement plant, large coal processing enterprises and Industrial crushing and grinding Cement grinding station can make full use of Industrial waste such as the slag , fly ash, furnace slag and coal gangue around the city, so it is an environmental protection industryChina Small Cement Clinker Grinding Mill Complete Plant Clinker kiln, also known as cement kiln, is the equipment used by cement plant for calcinating raw materials into clinker at extremely high temperature In the production process, raw materials are fed from the cold end of the clinker kilnCement Clinker Calcining In Clinker Kiln AGICO Cement Plant

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Design/Description Grinding system performance testing Physical inspection 3 CASE STUDY A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill);; heating the rawmix to sintering temperature (up to 1450 °C) in a cement kiln;; grinding the resulting clinker to make cement (see Cement mill); In the second stage, the rawmix is fed into the kiln and gradually heated by contact with the hot Cement kiln WikipediaBall Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD productioncement plant equipments manufacturer and suppliers of

Clinker And Gypsum Mixing In Vertical Mill Crusher Mills

clinker mill plant design We can supply all kinds vertical roller mill for grinding clinker,vertical cement mill, of mill feed Clinker, % Gypsum, per the raw mix design Raw mill The cooled and crushed clinker through chain bucket conveyer comes to clinker silo for storage, with capacity of 33000t, and storage life of 165 days The clinker out of silo is sent to the clinker batch silo before cement mill by belt conveyor 1111 Gypsum crushing and pozzolana transportation4000tpd Clinker New Technology Dry Process Turnkey Cement Plamer ducts, raw mill circuits, clinker cooler ducts, etc • Kiln ID Fans Fan designed with operating and continuous temperature between 300° and 400° C, with peaks up to 500° C Centre line supported fan and materials are selected for such temperaturesCEMENT PLANTS APPLICATIONS Boldrocchi Group

Clinker Grate Cooler for Cement Plant

Processing capacity: 8004000t/d; Applications: Cement, silicate products, new building materials, refractory materials, glass ceramics and other production industries; Applicable materials: limestone, cement clinker, bauxite, activated lime, aluminum hydroxide, bentonite, etc; Uses: The grate cooler is an important main equipment in the clinker burning system of the cement plantClinker Grinding Unit, Grinding unit manufacturer, ball mill for Our Cement Clinker Grinding unit can be obtained from 50 TPD to 1000 Cement clinker grinding unit design by the Clinker grinding plant is the last Clinker Grinding Plant Layout 200 TpdThis clinker grinding plant is comprised of material handling equipment, pre crusher, feed hopper, table feeders, ball mill and packing plant Designed to handle the broadest possible range of friable materials, this versatile clinker grinder incorporates a host of design features that improve efficiency and reliability in bottom ash handling CLINKER GRINDING PLANT, Size/Dimension: 14 28 Meters

Clinker Grinding Unit Manufacturers Suppliers in India

We provide high performing Clinker Grinding Plant that is ideal for the efficient grinding of the clinker to produce cement Our Cement Clinker Grinding Plant is comprised of Precrusher, feed hopper, Table feeders, Material Handling equipment, Ball mill, Blending and Packing Plant Our Cement Clinker Grinding Plant is availableSmall Cement Clinker Grinding Mill Complete Plant application in mine industry, cement plant, large coal processing enterprises and Industrial crushing and grinding Cement grinding station can make full use of Industrial waste such as the slag , fly ash, furnace slag and coal gangue around the city, so it is an environmental protection industryChina Small Cement Clinker Grinding Mill Complete Plant Civil Structural Design Detailing of Complete plant Structures Preheater tower, silos, clinker grinding plant, packing plant, lime stone crushur, Kiln, ball mill, cooler building, coal mill, Stock Pile, transfer towers and conveyors etc 8: M/S ICON CEMENTUAE: Enexco Teknologies India Limited: Silo capacity 1000 TonsCement Plants – STRUCON Consulting

CEMENT PLANTS APPLICATIONS Boldrocchi Group

mer ducts, raw mill circuits, clinker cooler ducts, etc • Kiln ID Fans Fan designed with operating and continuous temperature between 300° and 400° C, with peaks up to 500° C Centre line supported fan and materials are selected for such temperaturesYears of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needsVertical Roller Mills A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill);; heating the rawmix to sintering temperature (up to 1450 °C) in a cement kiln;; grinding the resulting clinker to make cement (see Cement mill); In the second stage, the rawmix is fed into the kiln and gradually heated by contact with the hot Cement kiln Wikipedia

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Design/Description Grinding system performance testing Physical inspection 3 CASE STUDY A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Processing capacity: 8004000t/d; Applications: Cement, silicate products, new building materials, refractory materials, glass ceramics and other production industries; Applicable materials: limestone, cement clinker, bauxite, activated lime, aluminum hydroxide, bentonite, etc; Uses: The grate cooler is an important main equipment in the clinker burning system of the cement plantClinker Grate Cooler for Cement PlantThe cooled and crushed clinker through chain bucket conveyer comes to clinker silo for storage, with capacity of 33000t, and storage life of 165 days The clinker out of silo is sent to the clinker batch silo before cement mill by belt conveyor 1111 Gypsum crushing and pozzolana transportation4000tpd Clinker New Technology Dry Process Turnkey Cement Pla

Cement Production Cement Howden

Cement mill Cement mill ID Fans Clinker and gypsum that are grinded by the cement mill The cement mill fan moves the product into the mill during grinding (Dunbar cement plant, UK), their existing Raw Mill fan was replaced with an enhanced Howden design in 2007 If you would like to submit an enquiry please get in touchCement plant is necessary for cement production, mainly consist of a series of cement equipment apply for preparation of cement raw materials, clinker production, and finished cement production, such as cement mill, cement crusher, rotary kiln, cement roller press, cement dryer, clinker cooler, cement silo, and related cement plant equipmentCement Plant, Cement Equipment Cement Plant Manufacturer Saboo Engineers Pvt Ltd has been playing stroke of excellence in the domain of heavy industrial machine, construction and cement Empowered with advanced technology machines and an experienced team of engineers, we have brought high efficiency Kiln Cement Plants, Clinker Grinding Plant, ball mill etc Adhering to strict quality, we design our products as per the national and international Manufacturer of Clinker Grinding Plant Cement Rotary