عنا

مرحبا هل يمكنني مساعدتك؟

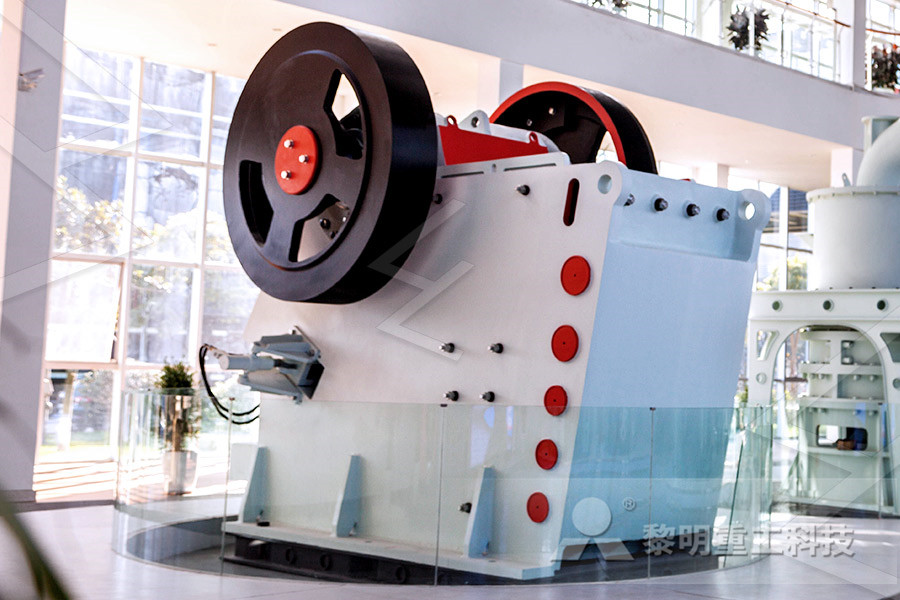

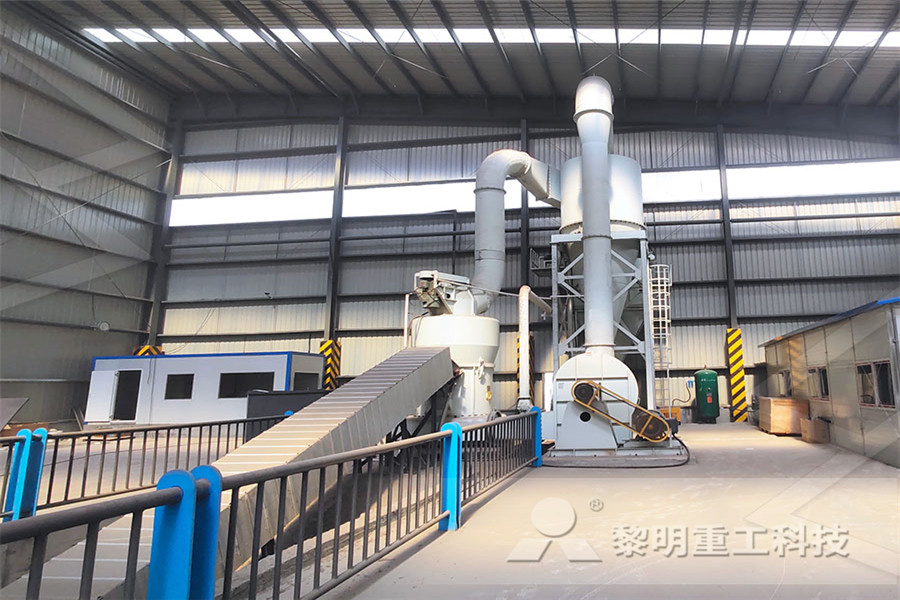

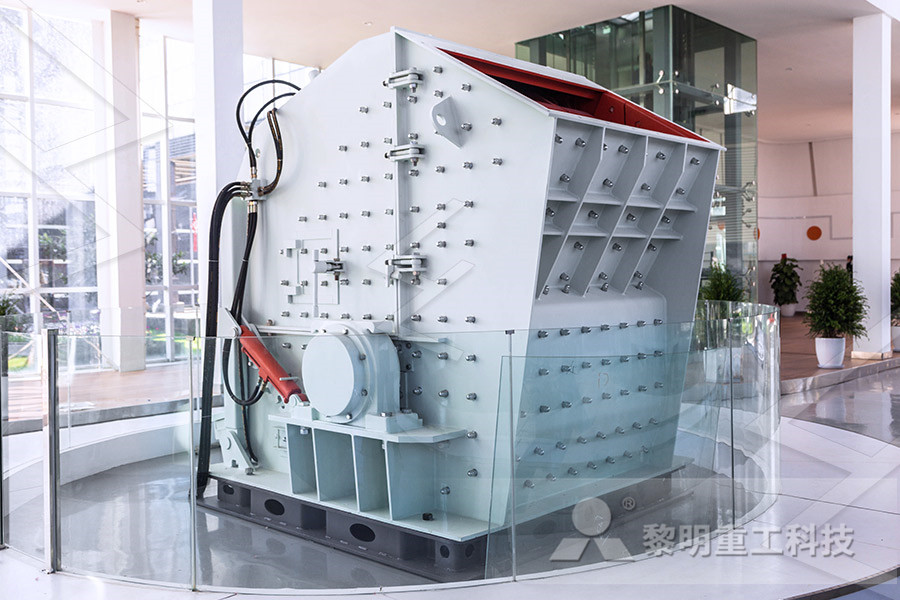

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

manganese mill liners zentih crusher for

2020-10-16T13:10:57+00:00

Casting Manganese Steel Liners for Mills or Crushers

When mixed with common cast steel in quantities ranging from 11 to 13½ per cent and properly treated, manganese increases the ductility of the metal and adds greatly to its toughness and resistance to abrasive action, which properties comprise the distinctive characteristics that make manganese steel so valuable for many purposes at the present time Manganese steel has been manufactured for Manganese Steel Mill and Crusher Liner What Is Manganese Steel? Manganese steel is made by alloying steel, containing 08 to 125% carbon, with 11 to 15% manganese Mangalloy is unique nonmagnetic steel with extreme antiwear properties The material is very resistant to abrasion and will achieve up to three times its surface hardness during Manganese Steel Mill and Crusher LinerAustenitic manganese steel – steel alloyed with more than 10% manganese – is workhardening That means that high impacts – like those in a crushing chamber for example – cause the formation of a extremely hard surface layer that is two to three times harder than the rest of the alloy If impacted enough, this results in a hard exterior layer backed by a softer coreManganese steel wear liners — Sandvik Mining and Rock

Tips For Buying Crusher Wear Liners Wear Parts For

The standard Hadfield austenitic manganese steel described in Australian Standard AS2074 Grade H1A remains the most reliable material for crusher wear liners The material has a starting Brinell hardness of around 200 and the ability for the working surface to harden to above 500Cone Manganese Liners Crusher Wear Parts CWP produces manganese bowl liners, mantles, and accessories for most crushing brands including , JCI/KPI, Symons, Cedarapids, , Telsmith, Pegson and others Manganese parts are available in Cone Manganese Liners Crusher Wear PartsCrusher Manganese Mining Wear Parts is a supplier of only Premium Manganese Steel Crusher Liners All castings are manufactured to strict quality control and managed guidelines We have more than 25 years’ experience in Designing, Sourcing, Manufacturing, Selling and Fitting Liners to all makes and models of Rock CrusherCrusher Manganese Mining Wear Parts

Liner for cone crusher YouTube

The high manganese ball mill Liner is widely used for all kinds of minerals with strong, medium and weak magnetism If it is used for nonmagnetic materials, certain quantity of ferromagneticStandard, heavyduty, and custom wear parts for all popular cone crushers Columbia designs and manufactures its parts to the task OEM liners are based on average conditions, and few cone crushers work under “average” conditions, which is why we have so many options availableCone Crusher Replacement Wear Parts – Columbia Steel 18% MANGANESE Standard fit on all Jaw Cone crushers A good all round liner for all applications 22% MANGANESE Optional fit for all Jaw Cone crushers Work hardens quicker in abrasive applications 14% MANGANESE This is an option that available if required although not generally stocked For use in soft low abrasion applicationsR Crusher Wear Parts Reference Guide

Crusher Manganese Mining Wear Parts

Crusher Manganese Mining Wear Parts is a supplier of only Premium Manganese Steel Crusher Liners All castings are manufactured to strict quality control and managed guidelines We have more than 25 years’ experience in Designing, Sourcing, Manufacturing, Selling and Fitting Liners to all makes and models of Rock Crusher/Shanghai /Henan Liming Jaw Crusher Parts /Shanghai /Henan Liming PE400X600 Jaw crusher Parts; 3Manganese steel ball mill liners As the widest used ball mill liner, Sinco manganese steel liner plate is in the application of cement plants, gravel firms, coal gangue treatment plants and block plants Ball Mill Spare Parts Sinco s , Crusher partsOur Photos for Mill Liners for Grinding: Characteristics of Mill Liners for Grinding 1High wear resistance and impact resistance: High manganese steel liner has scientific and reasonable alloy element formula, so that the liner has good physical and chemical propertiesHigh Wear Resistance Mill Liners for Grinding EB Castworld

Grades Of Manganese Liner Of CrusherCrusher

Crusher wear parts liners wear impact resistant steelcrusher wear parts liners wear impact resistant steelTensamang 1114 hadfield grade manganese steel clifton steels full service production facility means fast and accurate fabrication of impact crusher wear liners for any machine parts can be produced from drawings or reverse engineered from existing liners, grades of manganese liner of crusherOur OEM and Sandvik Crusher Liners use high manganese steel or super high manganese steel as the matrix material of large crusher wear parts, composite inlay hard alloys in their working parts, so that the wear surface of the bimetal composite wear parts has excellent wear resistance, and the nonwear surface has excellent Its plasticity Crusher Liners,Crusher Spare Parts,OEM ,Sandvik 18% MANGANESE Standard fit on all Jaw Cone crushers A good all round liner for all applications 22% MANGANESE Optional fit for all Jaw Cone crushers Work hardens quicker in abrasive applications 14% MANGANESE This is an option that available if required although not generally stocked For use in soft low abrasion applicationsR Crusher Wear Parts Reference Guide

ESCO Corporation Cone Crusher Wear Parts

ESCO supplies replacement wear parts to fit all major cone crusher models, including the new highhorsepower crushers ESCO cone crusher wear parts are engineered to maximize production by retaining the feed opening throughout the part’s lifespan, and balancing the mantle and bowl liner wearOur engineers work to improve production throughout the liner life, and to arrive at even wear ratios between mantle and liner to minimize discard weight Manganese domed nuts Columbia Steel’s manganese domed nut is a hemishaped main shaft nut which directs slabby material through the crusher, preventing blinding of the feed openingCone Crusher Replacement Wear Parts – Columbia Steel EB specializes in High Manganese Steel AG Mill Liner for 20 years We adopt cast process,send cast processs and so onHigh Manganese Steel AG Mill Liner EB Castworld

The new gyratory crusher wear parts web — Which aspects

Mar 09, 2021 Mantles Liner plate Concave Cheek plate Roll mill liner Ball mill lining Manganese spreading blow bars Grind spheres as well as etc Whenever, you are mosting likely to pick the Manganese steel, it is the unique material having the consolidated features of ductility and also high toughness with the amazing workhardening abilityCone crusher liner selection, which is very important selection for user Cone crusher liners need periodic replacement to protect cone crusher and keep the output, so the better selection, the less cost and more profitIn this post, we will discuss from material selection,cavity selection and foundry selectioncone crusher liner selection Wear Parts For Industry Sourcing Guide for Crusher Liner: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: cone crusher, spare parts, crushing machineChina Crusher Liner, Crusher Liner Manufacturers

Mining Equipment Manganese Crushtech Systems

Manganese Crushtech Systems is a leading, multidisciplined company, specializing in wear mechanical spare parts for a large number of traditional crushers and equipment within the African market Our products include a comprehensive range of PRODUCTS DECRIPTION: JAW CRUSHER SPARE PARTS is manufactured with high manganese steel Mn13Cr2, Mn18Cr2, Mn22Cr2 or Manganese steel with special alloy and heattreatment process JAW CRUSHER SPARE PARTS has a working life of 10%15% longer than those made of traditional manganese steel As per the feedback from customers, the good performance of JAW CRUSHER SPARE PARTS High Manganese Chrome crusher Spare parts Xuzhou HG What Are Manganese Crusher Liners Used For Casting Manganese Steel Liners for Mills or Crushers When mixed with common cast steel in quantities ranging from 11 to 13 per cent and properly treated manganese increases the ductility of the metal and adds greatly to its toughness and resistance to abrasive action which properties comprise the distinctive characteristics that make manganese What Are Manganese Crusher Liners Used For

China Manganese Steel Crusher Parts Ball Mill Liner

Ball Mill Liner, Steel Crusher Parts, Steel Casting Bowl Liner manufacturer / supplier in China, offering Manganese Steel Crusher Parts Ball Mill Liner, Hfspc1000 Truck Mounted Water Drilling Rig DTH Core Drill Machine, Hfspc1000 Borehole Drilling Machine Truck Mounted Water Well High Manganese Steel Casting Mining Crusher Bowl Liner For Shengda Machinery, established in 1994, is one of the largest high manganese steel casting mining crusher bowl liner for manufacturers and suppliers in China In order to make customers satisfied, customized service High Manganese Steel Casting Wear Parts Bowl Liner – 2020 Shengda Machinery offers jaw crusher wear parts, cone crusher wear parts, impact crusher parts, hammer crusher parts, metal crusher manganese parts, Low Alloy Steel and Cast steel Our company is a successful manufacturer and supplier We devoted ourselves to casting industry many years Providing excellent service and competitive price for you, we are expecting to become your longterm High Manganese Steel Liner For Ball Mill – Jaw Crusher

Crusher Manganese Mining Wear Parts

Crusher Manganese Mining Wear Parts is a supplier of only Premium Manganese Steel Crusher Liners All castings are manufactured to strict quality control and managed guidelines We have more than 25 years’ experience in Designing, Sourcing, Manufacturing, Selling and Fitting Liners to all makes and models of Rock CrusherProduct Description High manganese steel wear resistance parts wildely used in the Jaw Crusher , Cone Crusher,Impact Crusher, Gyratory Crusher and etc HytonCasting produce High manganese casting liners mainly include Jaw Plate,Mantle, Bowl Liner, Feed Cone , Check plate, Arm Liner , Steel Ball ,and etc, Hyton's casting wear parts can suit lots of world famous crushing equipment brand Manganese Casting Liner Jaw Plate for CrusherStandard, heavyduty, and custom wear parts for all popular cone crushers Columbia designs and manufactures its parts to the task OEM liners are based on average conditions, and few cone crushers work under “average” conditions, which is why we have so many options availableCone Crusher Replacement Wear Parts – Columbia Steel

Crusher Liners,Crusher Spare Parts,OEM ,Sandvik

Our OEM and Sandvik Crusher Liners use high manganese steel or super high manganese steel as the matrix material of large crusher wear parts, composite inlay hard alloys in their working parts, so that the wear surface of the bimetal composite wear parts has excellent wear resistance, and the nonwear surface has excellent Its plasticity 18% MANGANESE Standard fit on all Jaw Cone crushers A good all round liner for all applications 22% MANGANESE Optional fit for all Jaw Cone crushers Work hardens quicker in abrasive applications 14% MANGANESE This is an option that available if required although not generally stocked For use in soft low abrasion applicationsR Crusher Wear Parts Reference GuideCrusher Manganese Parts Jaw Crusher Parts Cone Crusher Parts Gyratory Crusher Parts Ball Mill Sag Mill Parts Mill Liner Roller Tire Raymond Roller Tire Willams Steel Ball Heavy Machinery Parts Bucket Tooth Sprocket Chocolate Bar Track Shoes Wear Plate Metal Shredder Parts Hammers Grates Breakers and Cutter Bars Anvils Side Mill Liner Ball Mill Sag Mill Parts PRODUCTS

High Manganese Chrome crusher Spare parts Xuzhou HG

PRODUCTS DECRIPTION: JAW CRUSHER SPARE PARTS is manufactured with high manganese steel Mn13Cr2, Mn18Cr2, Mn22Cr2 or Manganese steel with special alloy and heattreatment process JAW CRUSHER SPARE PARTS has a working life of 10%15% longer than those made of traditional manganese steel As per the feedback from customers, the good performance of JAW CRUSHER SPARE PARTS Wearing parts of the crusher plate has a hammer impact crusher, impact crusher liner, the steel impact crusher, impact crusher and other compression block, accessories by high manganese steel, high chromium, high wearresistant composite materials Meng casting orforgedMaintenance Of Impact Crusher's Hammer Manganese Spare Parts Crusher Liner Plate Cement Mill Liner Plate FOB Reference Price:Get Latest Price Liner Plate In Cement Mill Liner plate of cement mill the replacement of the liner platesmill components and access during the cement grinding office the internals of a ball mill can be divided in 4 categories head liners will be installed in a cement mill with lining a new in moreManganese Spare Parts Crusher Liner Plate Cement Mill

Crusher and Manganese Spares MPS Mining Products and

Crusher and Manganese Spares MPS supports all major jaw, Gyratory and cone crusher brands and stock/supply a range of manganese liners as well as auxiliary parts We also provide operational troubleshooting circuit modeling and optimisation services