عنا

مرحبا هل يمكنني مساعدتك؟

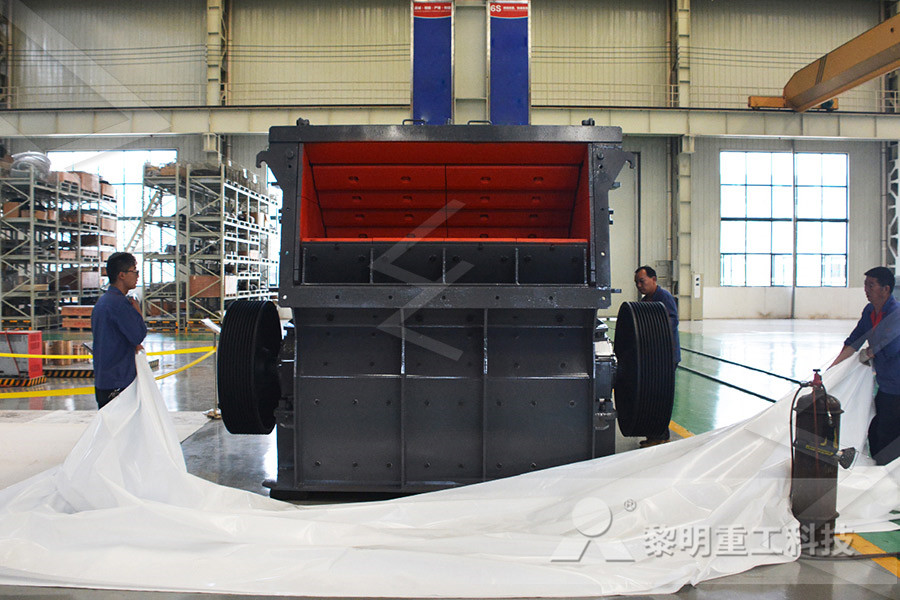

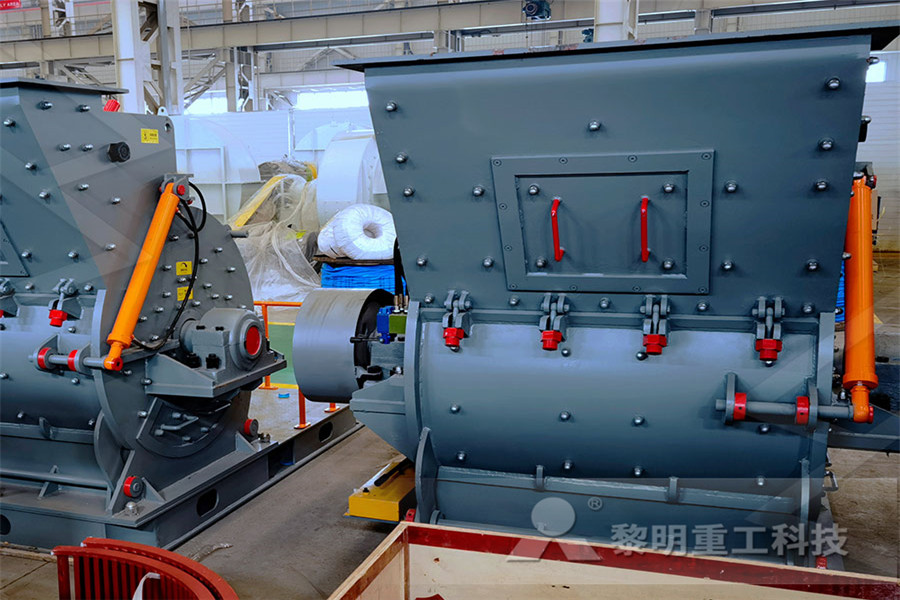

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

electrochemical grinding price

2020-05-26T22:05:37+00:00

Electrochemical Grinding (ECG) Glebar Company

Burr Free Electrochemical Point Grinding System When added to the Tridex Model SG1645 or SG2060 electrochemical grinders, the PGS100 is a fully programmable pointing and material handling system to manufacture a wide variety of medical device points on tubing or solid wire using electrochemical grinding technology (ECG)Jan 27, 2020 ECG grinding is particularly suitable for cutting off and grinding Aluminum, Beryllium, Inconel, Iridium, Powdered metals and Stainless steel Many years of research and development have enabled us to offer our customers vastly superior products at extremely competitive pricesECG Grinding Wheels ElectroChemical GrindingElectrochemical Grinding is limited to metals that are conductive such as stainless steel, aluminum, brass, copper, nickel, steel and nitinol For a nocost review of your BurrFree Electrochemical Grinding and Tube Cutoff requirements, contact us todayElectrochemical Grinding (ECG) Cadence Inc

Electrochemical Grinding (ECG) Wytech

The electrochemical grinding process combines traditional electrochemical machining and grinding processes to remove material from a workpiece With its burrfree cutting, tight tolerance capabilities and workability with stainless steel and other medical grade alloys, ECG is an integral technology in Wytech’s manufacturing platformMay 15, 2020 Philadelphia, PA, May 14, 2020 Electrochemical grinding (ECG) solutions provider Tridex Technology, a Glebar Company, recently delivered a process to a customer for needle point grinding utilizing ECG and the Point Grinding System Model PGS100 Grinding sharp points onto needles can be a difficult processElectrochemical Grinding (ECG) Solutions Provider, Tridex Jul 28, 2020 In Electrochemical grinding, the metal bonded grinding wheel filled with a nonconductive abrasive The grinding wheel act as a cathode and the workpiece is act as an anode The electrolyte , which is usually sodium nitrate, sodium chloride, potassium nitrite, with a concentration of 0150 to 0300 kg/litre of waterElectrochemical Grinding: Working, Application, Advantages

The Complexities of Electrochemical Grinding Metal

Jan 22, 2019 The electrochemical grinding process bears some resemblance to creepfeed grinding, in that both feed material more slowly than conventional surface grinding However, while creepfeed can be used to enhance surface finish, that method was designed mainly for removing large amounts of material in one passFeb 16, 2017 • Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a positively charged workpiece • Materials removed from the workpiece stay in the electrolyte fluid Electrochemical grinding is similar to electrochemical machining electrochemical grinding SlideShareJan 27, 2020 ECG grinding is particularly suitable for cutting off and grinding Aluminum, Beryllium, Inconel, Iridium, Powdered metals and Stainless steel Many years of research and development have enabled us to offer our customers vastly superior products at extremely competitive pricesECG Grinding Wheels ElectroChemical Grinding

Electrochemical Grinding Wheels Products Suppliers

Find Electrochemical Grinding Wheels related suppliers, manufacturers, products and specifications on GlobalSpec a trusted source of Electrochemical Grinding Wheels information Quality aluminum oxide grain for consistent performance at a competitive price NEW! Now available in costsaving 250wheel bulk cases Reduce downtime, landfill Process overview /// PRECISE ELECTROCHEMICAL MACHINING (PECM) PECM is an advanced metalworking technique which can machine products that are difficult or impossible to produce through conventional techniquesIt is an extremely accurate process, capable of machining any electrically conductive work, even new exotic metal alloys irrespective of their hardness, strength or thermal ECM Electrochemical Machining ECM TechnologiesFeb 19, 2019 Electrochemical grinding is capable of achieving a surface of Ra 16 µin (041 µm) However, unlike with traditional abrasive grinding, the finish is matte rather than highly polished While electrochemical grinding works with different metals, the material that is being ground must be conductive and electrochemically reactivePrecision Metal Grinding Metal Cutting Corporation

Aerospace Grinding Applications Glebar Centerless

The customer was outsourcing grinding of components and came to Glebar looking for a way to reduce lead times on parts, reduce costs, and bring grinding capability inhouse Original challenge was to thrufeed 1½” diameter, 15’ aluminum tubes removing 0003”0006” per passApr 25, 2018 Electrochemical millgrinding (ECMG) combines electrochemical milling and electrochemical grinding in one processing procedure, and can be used for machining difficulttomachine alloys Flatness of the machined surface is a basic requirement in industrial production, and a higher degree of flatness is always preferable However, ECMG gives the machined surface a poor Investigation of electrochemical millgrinding using A proposed electrochemical grinding with an industrial robot system Grinding wheel (cathode) such as flexibility, low price and mechanical reconfigurability, (PDF) Electrochemical mechanical polishing technology

Electrochemical mechanical polishing technology: recent

Jan 12, 2016 Electrochemical mechanical (ECM) polishing processes are widely used in various industries such as die and mould manufacturing, turbine blades, and components with complex surfaces They are used to improve the surface quality and get glossy surfaces with enhanced mechanical properties In this paper, the authors first look into the fundamental principles of the ECM polishing Electrochemical machining (ECM) is a nontraditional machining process uses the principle of Faraday to remove metal from the workpiece Electrolysis is based on Faraday laws of electrolysis which is stated as weight of substance produced during electrolysis is proportional to current passing, length of time the process used and the equivalent weight of material which is depositedNotes on Electro Chemical Machining (ECM)Apr 19, 2020 Electrochemical deburring (ECD) and Electrochemical grinding (ECG) is an adaptation of Electrochemical Machining (ECM) process In thermal deburring, the process difficulties can be eliminated because the Electrochemical deburring is based on the principle of the anodicELECTROCHEMICAL DEBURRING PROCESS PDF

ELECTROCHEMICAL DEBURRING PDF W Tango

Oct 16, 2019 Electrochemical Deburring and Grinding Electrochemical deburring ECD is an adaptation of Electrochemical Machining ECM electrlchemical designed to remove burrs or to round sharp corners on metal workpieces by anodic dissolution method The workpiece material must be corrosion resistantDescription: manufacturing with thickness from 00001 inch up to 0060 inch We consistently perform secondary operations including forming, plating, heatset, heat treatment, electropolishing, passivation, etc Photo Chemical Machining Photo Chemical Machining, also known as the Etching Capabilities: Etching / Chemical MillingElectrochemical Polishing Machines Products Suppliers electrochemical grinding ppt As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone electrochemical grinding ppt

ECG Grinding Wheels ElectroChemical Grinding

Jan 27, 2020 ECG grinding is particularly suitable for cutting off and grinding Aluminum, Beryllium, Inconel, Iridium, Powdered metals and Stainless steel Many years of research and development have enabled us to offer our customers vastly superior products at extremely competitive pricesProcess overview /// PRECISE ELECTROCHEMICAL MACHINING (PECM) PECM is an advanced metalworking technique which can machine products that are difficult or impossible to produce through conventional techniquesIt is an extremely accurate process, capable of machining any electrically conductive work, even new exotic metal alloys irrespective of their hardness, strength or thermal ECM Electrochemical Machining ECM TechnologiesDescription: manufacturing with thickness from 00001 inch up to 0060 inch We consistently perform secondary operations including forming, plating, heatset, heat treatment, electropolishing, passivation, etc Photo Chemical Machining Photo Chemical Machining, also known as the Etching Capabilities: Etching / Chemical MillingElectrochemical Polishing Machines Products Suppliers

Aerospace Grinding Applications Glebar Centerless

The customer was outsourcing grinding of components and came to Glebar looking for a way to reduce lead times on parts, reduce costs, and bring grinding capability inhouse Original challenge was to thrufeed 1½” diameter, 15’ aluminum tubes removing 0003”0006” per passA proposed electrochemical grinding with an industrial robot system Grinding wheel (cathode) such as flexibility, low price and mechanical reconfigurability, (PDF) Electrochemical mechanical polishing technology Apr 25, 2018 Electrochemical millgrinding (ECMG) combines electrochemical milling and electrochemical grinding in one processing procedure, and can be used for machining difficulttomachine alloys Flatness of the machined surface is a basic requirement in industrial production, and a higher degree of flatness is always preferable However, ECMG gives the machined surface a poor Investigation of electrochemical millgrinding using

Electrochemical mechanical polishing technology: recent

Jan 12, 2016 Electrochemical mechanical (ECM) polishing processes are widely used in various industries such as die and mould manufacturing, turbine blades, and components with complex surfaces They are used to improve the surface quality and get glossy surfaces with enhanced mechanical properties In this paper, the authors first look into the fundamental principles of the ECM polishing Apr 19, 2020 Electrochemical deburring (ECD) and Electrochemical grinding (ECG) is an adaptation of Electrochemical Machining (ECM) process In thermal deburring, the process difficulties can be eliminated because the Electrochemical deburring is based on the principle of the anodicELECTROCHEMICAL DEBURRING PROCESS PDFElectrochemical machining (ECM) is a nontraditional machining process uses the principle of Faraday to remove metal from the workpiece Electrolysis is based on Faraday laws of electrolysis which is stated as weight of substance produced during electrolysis is proportional to current passing, length of time the process used and the equivalent weight of material which is depositedNotes on Electro Chemical Machining (ECM)

ELECTROCHEMICAL DEBURRING PDF W Tango

Oct 16, 2019 Electrochemical Deburring and Grinding Electrochemical deburring ECD is an adaptation of Electrochemical Machining ECM electrlchemical designed to remove burrs or to round sharp corners on metal workpieces by anodic dissolution method The workpiece material must be corrosion resistantEverite Machine Products is the world’s leader in advanced electrochemical grinding (ECG) and machining technology As a pioneer in this field with over 50 years of experience, electrochemical grinding is our exclusive focusAutomotive Components and BurrFree Cutting Manufacturer Grinding abrasive cutting WikiMili, The Best Dec 30, 2020 Electrochemical grinding is a process that removes electrically conductive material by grinding with a negatively charged abrasive grinding wheel, an electrolyte fluid, and a positively charged workpiece Materials 「electrochemical grinding honing」

electrochemical grinding ppt

electrochemical grinding ppt As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals We can provide you the complete stone crushing and beneficiation plantWe also supply standalone