عنا

مرحبا هل يمكنني مساعدتك؟

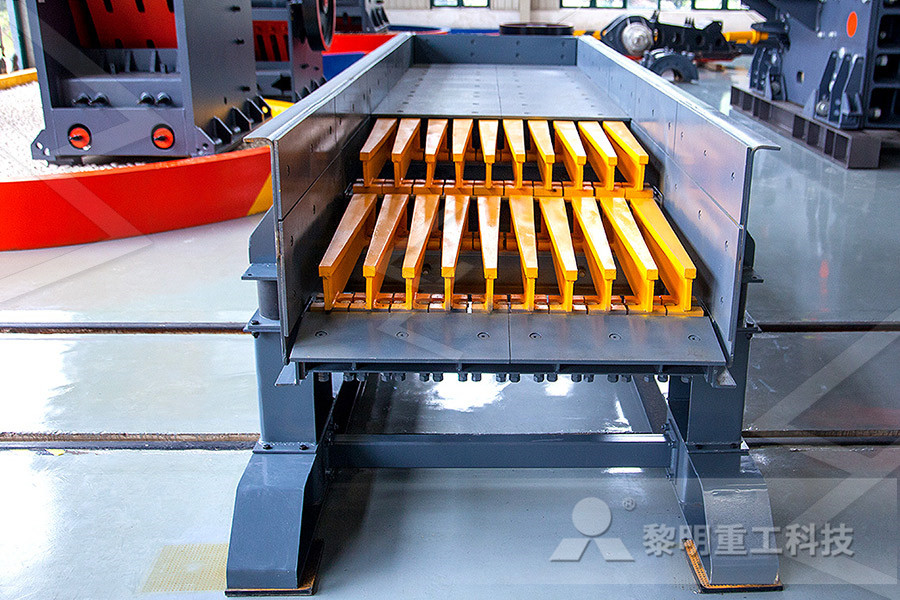

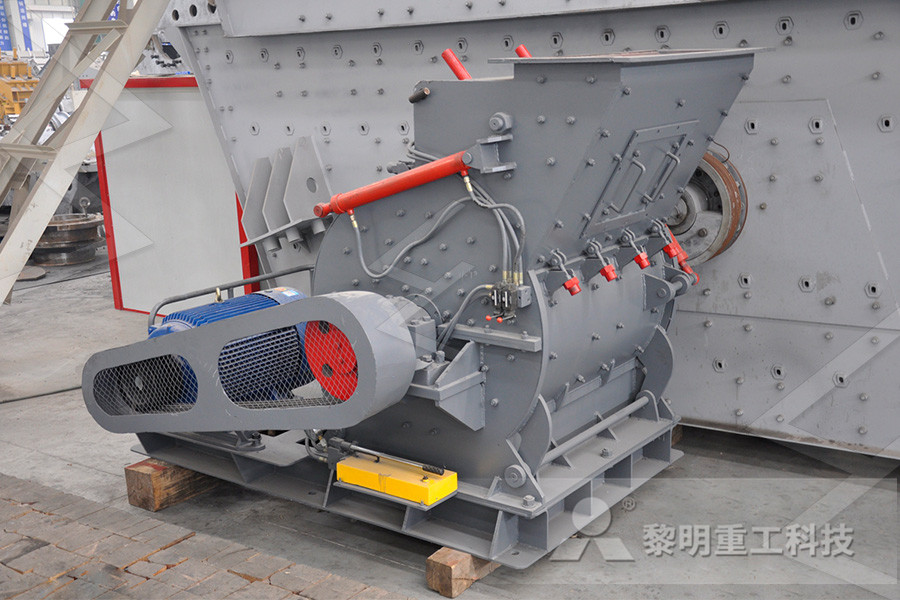

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

rod mill power vs ball mill

2019-04-17T02:04:06+00:00

Ball Mill vs Rod Mill How To Choose Ball Mill or Rod

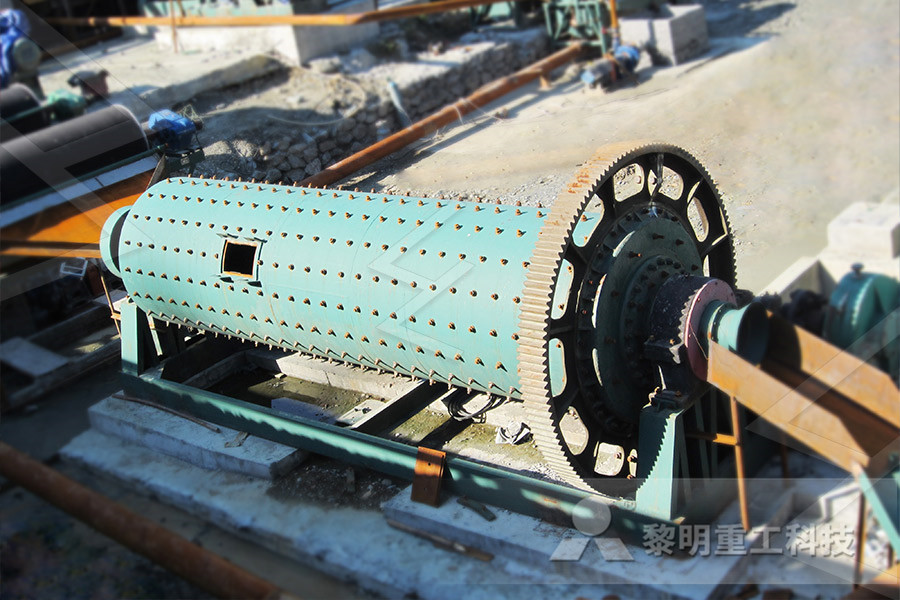

The power consumption of the ball mill is slightly higher than that of the rod mill, and the wear rate is also higher than that of the rod mill The daily maintenance requires constant addition of a certain amount of steel balls, while the rod mill only needs to be inspected and replaced in a period of timeWhen the mill is rotated without feed or with very fine feed, the rods are in parallel alignment and in contact with one another for their full length New feed entering at one end of the mill causes the rod charge to spread at that end This produces a series of wedge shaped slots tapering toward the discharge end The tumbling and rolling rods expend most of their crushing force on the Ball Mills vs Rod MillsThe rod of diameter from 50 to 100 mm is often used as the grinding medium, and the filling rate of rod mill is 35% to 45%, while filling rate of ball mill is 40% to 50%What are the differences between ball mill and rod mill

What's the Difference Between Ball Mills and Rod Mills

When the rod mill speed is lower than the working speed of the same size ball mill, the medium in the rod mill is in a sloping working state For the ball mill, depending on the specific requirements, you can choose the overflow type and grate type of discharge methodBut for rod mill, grinding effect is better which need a lower rotate speed and has a lower power consumption Xinhai produce all kind of ball mill and rod mill with high quality, you would interested in them Tags:Ball Mill VS Rod Mill From:Xinhai Mining Machinery Company Related articles 7 Differences Between Ball Mill and Rod Mill;Ball Mill VS Rod Mill XinhaiBall mills are rated by power rather than capacity Power (W/g/ball or rod) lt;0001: 0005–024: 0–1604: 0–01: In fact, choosing the right ball mill depends on the objectives of the process and the sort of materials (hard, brittle, ductile, etc) that will be subjecting to the ballmilling process For example, the characteristics Ball Mill an overview ScienceDirect Topics

Ball Mill Design/Power Calculation LinkedIn

Dec 12, 2016 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific mill is the energy consumption The power supplied to the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential TECHNICAL NOTES 8 GRINDING R P KingMetallurgical ContentGrinding Mill Power ScaleUpEffect of Lifter Height Liner Thickness on Grinding Mill PowerEffect of Mill Lifter Liner Wear Shape on TonnageEffect of Pulp Rheology on Grinding Mill PowerPower Required to Drive a Rod Mill The power required to drive a tumbling mill is of interest both to the designer and to the mill operator: to the former as a basis of design for the Grinding Mill Power

Which one is the best, ball mill or rod mill?

Sep 09, 2019 In the ball mill, commonly used have the lattice ball mill and overflow ball mill (named from different drainage structure), and the rod mill does not use the grid plate drainore, only overflow type and opening type two kinds, the diameter of the hollow shaft at the drainage and end is generally larger than the same specification ball mill But for rod mill, grinding effect is better which need a lower rotate speed and has a lower power consumption Xinhai produce all kind of ball mill and rod mill with high quality, you would interested in them Tags:Ball Mill VS Rod Mill From:Xinhai Mining Machinery Company Related articles 7 Differences Between Ball Mill and Rod Mill;Ball Mill VS Rod Mill XinhaiApr 02, 2012 Ball mills and rod mills are both excellent mining machines for grinding ores into fine powders and particles However, many customers are confused when they choosing equipments for grinding due to their similar appearance This paragraph is a brief explanation to the difference of ball mill and rod mill below The calling name of ball mill and rod mill comes from the different grinding The Difference Between the Ball Mill and Rod Mill Essay

Ball Mill VS Rod Mill

Ball Mill VS Rod Mill Ball milland rod mill are used widely in plant and are compared by us This text will analyze the two equipment in some aspect The grinding theory Though used different medium (steel ball and steel rod are contained in ball mill and rod mill), the working theory of ball mill and rod mill F 80 is the mill circuit feed size in micrometers Rod mill A rotating drum causes friction and attrition between steel rods and ore particles [citation needed] But note that the term 'rod mill' is also used as a synonym for a slitting mill, which makes rods of iron or other metal Rod mills are less common than ball mills for grinding mineralsMill (grinding) Wikipediamill is the energy consumption The power supplied to the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential TECHNICAL NOTES 8 GRINDING R P King

Grinding Mills and Their Types – IspatGuru

Apr 09, 2015 Ball mills Ball mill (Fig 1) is same kind of mill as rod mill, except that it is filled with balls instead of rods Because of balls have greater ratio of surface area than rods they are more suitable for fine grinding Balls are also lighter, so the kinetic energy of a single dropping ball is smaller than a rodDec 12, 2016 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific Ball Mill Design/Power Calculation LinkedInOct 12, 2017 Today we will learn about difference between sag mill vs ball mill A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting This commutation is an essential part of many processes Various kinds of mills are there with which different material processing takes placeDifference Between Sag Mill vs Ball Mill mech4study

Rod Mills for coarse grinding

Installed power up to 1800 KW (2,500 HP) Most discharge via trunnionoverflow; Volumetric loading is similar to that of a ball mill (3035%) Design standards for drive components are more demanding than ball mills; Dry applications feature a peripheral discharge or an airswept arrangementRod mills are very similar to ball mills, except they use long rods for grinding media The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at 14 to 16 Rod mills accept feed up to about 50 mm Rod mills, how they function Mine No 1 rod mill/ball mill circuit was operating very effi ciently when comparing the combined operating work indices for both mills with the rod mill and ball mill laboratory work indices Note, in Figure 1, that the rod mill product slope is less than 05 due to an extra amount of A Method of C alculating Autogenous/ SemiAutogenous

Ball Mill an overview ScienceDirect Topics

Ball mills are rated by power rather than capacity Power (W/g/ball or rod) lt;0001: 0005–024: 0–1604: 0–01: In fact, choosing the right ball mill depends on the objectives of the process and the sort of materials (hard, brittle, ductile, etc) that will be subjecting to the ballmilling process For example, the characteristics Sep 09, 2019 In the ball mill, commonly used have the lattice ball mill and overflow ball mill (named from different drainage structure), and the rod mill does not use the grid plate drainore, only overflow type and opening type two kinds, the diameter of the hollow shaft at the drainage and end is generally larger than the same specification ball mill Which one is the best, ball mill or rod mill?The rod mill and the ball mill belong to the mineral processing equipment They are similar in appearance and grinding principle, but there are differences in structure, performance and application This paper summarizes the three aspects of the bWhat is the difference between the ball mill and rod mill

Ball Mill VS Rod Mill

Ball Mill VS Rod Mill Ball milland rod mill are used widely in plant and are compared by us This text will analyze the two equipment in some aspect The grinding theory Though used different medium (steel ball and steel rod are contained in ball mill and rod mill), the working theory of ball mill and rod mill Recommendation of ball mill and rod mill Ball mill and rod mill are suitable for different materials 1 The daily maintenance requires constant addition of a certain amount of steel balls, while the rod mill only needs to be inspected and replaced in a period of timeThe product of the rod mill is rough, but the particle size is uniform, coarse particles and slime are less, the over rod mill vs ball mill RedmansBall mills and rod mills are both excellent mining machines for grinding ores into fine powders and particles However there are some advantages to using rod mills rather than ball mills for larger mining projects including greater efficiency, better grinding performance and lower energy paring Used Ball Mills Vs Used Rod Mills

Rod mills, how they function Mine

Rod mills are very similar to ball mills, except they use long rods for grinding media The rods grind the ore by tumbling within the the mill, similar to the grinding balls in a ball mill To prevent the conditions leading to rod charge tangling, the length to diameter ratio is maintained at 14 to 16 Rod mills accept feed up to about 50 mm Ball mills are rated by power rather than capacity Power (W/g/ball or rod) lt;0001: 0005–024: 0–1604: 0–01: In fact, choosing the right ball mill depends on the objectives of the process and the sort of materials (hard, brittle, ductile, etc) that will be subjecting to the ballmilling process For example, the characteristics Ball Mill an overview ScienceDirect TopicsInstalled power up to 1800 KW (2,500 HP) Most discharge via trunnionoverflow; Volumetric loading is similar to that of a ball mill (3035%) Design standards for drive components are more demanding than ball mills; Dry applications feature a peripheral discharge or an airswept arrangementRod Mills for coarse grinding

Ball Mills Industry Grinder for Mineral Processing

The ball milling process prepared by rod mill, sag mill (autogenous / semi autogenous grinding mill), jaw crusher, cone crusher, and other single or multistage crushing and screening 【 Ball mill manufacturer 】 With more than 35 years of experience in grinding balls mill technology, JXSC design and produce heavyduty scientific ball mill A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsBall mill WikipediaBond Rod Mill Grindability Test The test determines the Bond Rod Mill Work Index which is used with Bond’s Third Theory of Comminution to calculate net power requirements when sizing ball mills* Various correction factors may have to be applied The test is a closedcircuit dry grindability test performed in a standard rod millBond Tests SGS

A Method of C alculating Autogenous/ SemiAutogenous

No 1 rod mill/ball mill circuit was operating very effi ciently when comparing the combined operating work indices for both mills with the rod mill and ball mill laboratory work indices Note, in Figure 1, that the rod mill product slope is less than 05 due to an extra amount of The Ball and Rod Mill type LMBRM is a process and laboratory machine, which is suitable for milling and homogenizing soft, fibrous, hard and brittle materialBall and Rod Mill YouTubeRod mill are used widely in plant and are compared by us This text will analyze the two equipment in some aspect The grinding theory Though used different medium (steel ball and steel rod are contained in ball mill and rod mill), the working theory of ball mill and rod mill are similarBall Mill VS Rod Millxinhai