عنا

مرحبا هل يمكنني مساعدتك؟

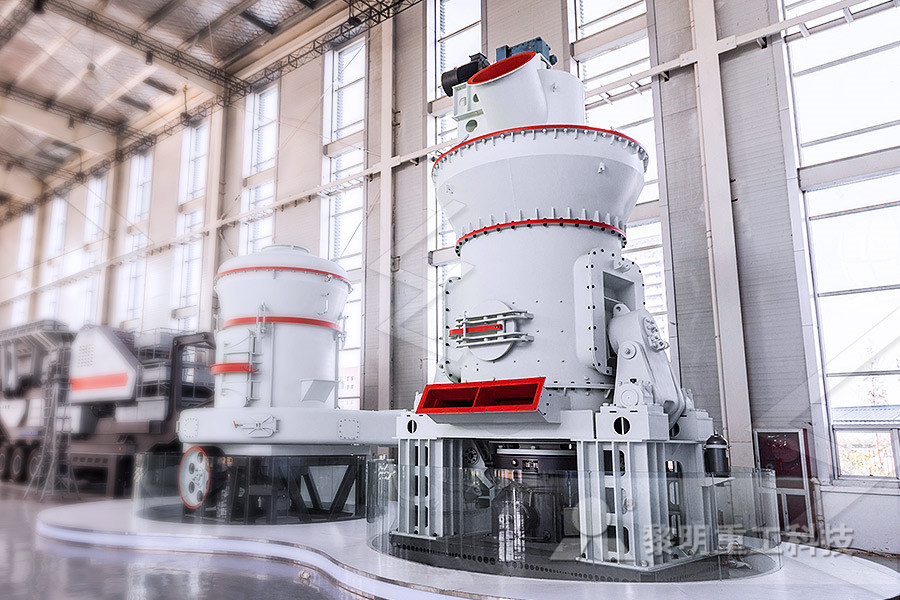

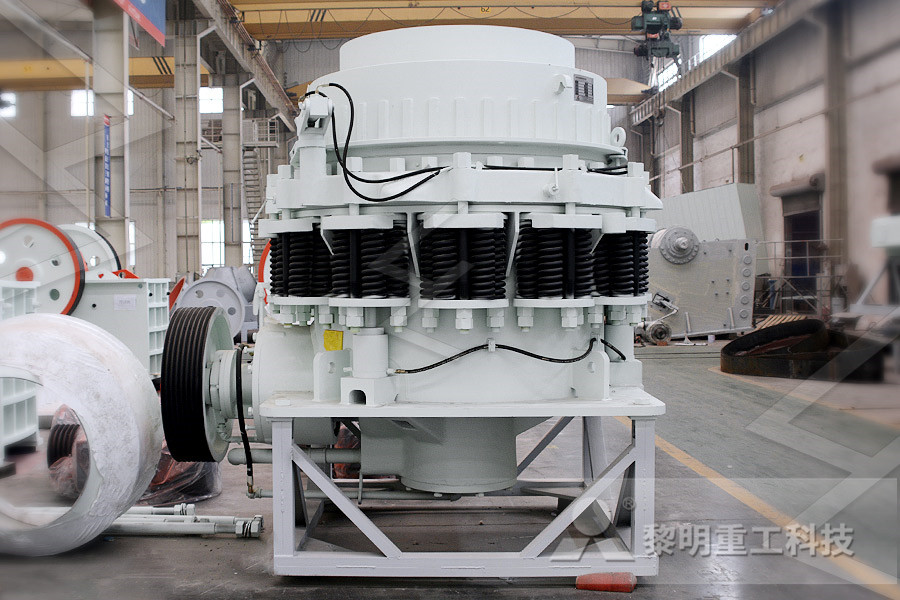

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

power plants fgd limestone slurry processes

2021-11-12T05:11:05+00:00

POWER PLANTS FGD LIMESTONE SLURRY PROCESSES

POWER PLANTLIMESTONE SLURRY PROCESS SINGLE PASS PROCESS Two Silos w/ Dual Outlets Direct to Two Dual Mixer Processes Pulverized Limestone Storage Two silos w/ Dual Cone Outlets VACUCAM® LIMESTONE SLURRY PROCESS DUAL EJECTOR MIXER SINGLE PASS INLINE SLURRY DIRECT TO SLURRY STORAGE 30%+ Slurry to Storage TankUtilizing the VACUCAM® Ejector Mixer Slurry Process for producing limestone slurries offers major benefits for FGD in Power Plants that cannot be achieved with other processes Optimize Slurry Quality and Scrubbing Efficiency Lower Initial Capital CostsLimestone Slurry Flue Gas Scrubbing Power GenerationSemiBulk Systems has applied its technology and experience in Powder Handling Powder/Liquid Mixing to provide the most efficient Limestone Handling/ Slurry Processes for FGD The Technology offers many benefits over conventional slurry processesPOWER PLANTS FGD LIMESTONE SLURRY PROCESSES w/

Power Plants Limestone Slurry for FGD Process XstreamLining!

Group Engineers Associates relating to the Crist Plant FGD project Power Plants Limestone Slurry for FGD In September 2007, two vans of Southern Company Engineers and other Power Plant design teams traveled to Indiana to visit NIPSCO's Power Plant utilizing the VACUCAM® Ejector Mixer process for slurring pulverized limestone for FGD The system hadJul 23, 2009 At Cottam power station, pumping the limestone slurry into the four FGD plants, together with the removal of the gypsum slurry and the wastewater treatment duties is handled by some 40 Wernert NE pumps of varying sizes and delivery outputsSlurry handling in FGD plants World PumpsNov 01, 2018 Coalfired power plants can significantly improve wet limestone scrubbing with advanced process control One optimization system implemented at a Japanese facility utilized enhanced regulatoryAdvanced Process Control for Optimizing Flue Gas

CoalFired Power MO: Enhancing WetLimestone Scrubber

Feb 08, 2019 The process is a classic example of an aqueous acidbase chemistry reaction applied on a large industrial scale, where alkaline limestone slurry Limestone Slurry Oxidation Air Sat Water Absorber Bleed Stream Flue Gas Water Vapor zScrubber Slurry Solids – Important WFGD process variable, verified daily with laboratory samples – Scrubber slurry solids: gypsum, limestone, flyash, inerts – Numerous inputs affecting water balance and solids concentration – Control solids concentrationWet FGD System Overview and Operation WPCApower plants fgd limestone slurry processes POWER PLANTS FGD LIMESTONE SLURRY PROCESSES POWER PLANTS –FGD LIMESTONE SLURRY PROCESSES NEW PROCESS TECHNOLOGY VS TRADITIONAL Pulverized Limestone wOur crushers are designed and built with advanced technology and stringent quality control at every stage of the manufacturing process, to power plants fgd limestone slurry processes

Limestone Slurry Flue Gas Scrubbing Power Generation

The most efficient FGD processes for making Limestone Slurry can be provided by using pulverized limestone vs the traditional wet ball mill process utilizing crushed limestone The wet ball mill process requires a considerable commitment by the power plant to operate a very inefficient process for crushed limestone handling on site and for power plants – fgd limestone slurry processes w/ pulverized limestone chemical handling, slurrying delivery processes for so2 hg treatment presented by: charles s alack semibulk systems, inc hot topic hour sept 2012POWER PLANTS FGD LIMESTONE SLURRY PROCESSES w/ Jul 23, 2009 Wet scrubber FGD plants play a critical role in reducing emissions of sulphur dioxide from coalburning power stations However, the abrasive and corrosive wet limestone slurry used in this process demands pumps of high levels of reliability Wernert pumps distributed by AxFlow in the UK provided the answer for one European power stationSlurry handling in FGD plants World Pumps

Flue Gas Desulphurization (FGD) plant 2 x 600 MW Coal

Flue Gas Desulfurization is a process of removing Sulphur Limestone Slurry Process 31 WET BALL MILL WITH RECIRCULATION SYSTEM WET BALL MILL Wet Ball Mills 32 Total Auxiliary power consumption for the FGD plant at 100% TMCR condition on firing worst coal is Limestone Slurry Oxidation Air Sat Water Absorber Bleed Stream Flue Gas Water Vapor zScrubber Slurry Solids – Important WFGD process variable, verified daily with laboratory samples – Scrubber slurry solids: gypsum, limestone, flyash, inerts – Numerous inputs affecting water balance and solids concentration – Control solids concentrationWet FGD System Overview and Operation WPCAAndo lists 47 indirect limestone/lime flue gas desulfurization plants operational in Japan at the end of 1977 (mostly sodium/calcium double alkali systems) He concludes that such processes are about equal to direct limestone/lime processes with regard to SO 2 removal efficiency, power consumption, and operability (Ando, 1977)Lime Slurry an overview ScienceDirect Topics

CoalFired Power MO: Enhancing WetLimestone Scrubber

Feb 08, 2019 The process is a classic example of an aqueous acidbase chemistry reaction applied on a large industrial scale, where alkaline limestone slurry reacts with acidic sulfur dioxide Figure 1May 25, 2015 The limestone slurry preparation system is for common use of 2 sets of FGD deviceThe limestone slurry preparation system is designed per uncer COAL E operation situation in 100% scope The limestone is transported by truck to grinding shop within desulphurization islandESP and FGD System: Limestone Slurry Preparation SystemWet limestone scrubbing has high capital and operati ng cost due to the handling of liquid reagent and waste Nonetheless, it is the preferred process for coalfired electric utility power plants burning coal due to the low cost of limestone and SO 2 control efficiencies from 90% up to 98% (Schnelle, 2002) SemiDry SystemsAir Pollution Control Technology Fact Sheet

when use limestone in power plant

The Use of Limestone Slurry Scrubbing to Remove Sulfur injection of either wet or dry limestone into the power plant furnace, we have chosen to use limestoneslurry scrubbing in the present case study Five hundred megawatts of electrical power (500 MWe) is to be generated in the present facilityRomania’s Largest Power Plant The FGD systems are designed to remove 964% of the SO2 and up to 80% of the fly ash from the boiler flue gas Each boiler of units 3 through 6 is equipped with an absorber unit, and there is a total of two limestone slurry preparation lines for the four boilers The flue gas SO2 absorption process produces a Yokogawa’s Integrated Solutions Control FGD Processes at FGD: SUSTAINABLE LIMESTONE PROCESSES VS TRADITIONAL (CONT) Option 1: Single Pass Process Direct Into Slurry Storage Tank(s) A single or a dual mixer can be mounted directly on the top of a slurry storage tank to provide a Single Pass Slurry Process at 30%+ slurry makeup on demand based on maintaining requirements for slurry storagePower Plants Modular engineered process solutions

Slurry Applications in The Flue Gas Desulfurization Process

Flue gas desulfurization is a set of technologies used to remove SO2 from exhaust flue gases of fossilfuel power plants, as well as from the emissions of other SO2 emitting processes One of the most integral parts of the FGD process is that of pumped slurry applications, which contain fluid properties consisting of both abrasives and solids , the flue exhaust gases from a coalfired power plant are commonly led through a spray of limestone slurry in a socalled scrubber The resultant reaction typically captures 90% or more of the SO 2 Approximately 8085% of worldwide FGD units installed in power plants use wet limestone scrubbing vs other technologies What happens to the SO 2 Analysis of limestone for flue gas desulfurization in a The most efficient FGD processes for making Limestone Slurry can be provided by using pulverized limestone vs the traditional wet ball mill process utilizing crushed limestone The wet ball mill process requires a considerable commitment by the power plant to operate a very inefficient process for crushed limestone handling on site and for Limestone Slurry Flue Gas Scrubbing Power Generation

Slurry handling in FGD plants World Pumps

Jul 23, 2009 Wet scrubber FGD plants play a critical role in reducing emissions of sulphur dioxide from coalburning power stations However, the abrasive and corrosive wet limestone slurry used in this process demands pumps of high levels of reliability Wernert pumps distributed by AxFlow in the UK provided the answer for one European power stationThe report gives results of a detailed comparative technical and economic evaluation of limestone slurry, generic double alkali, and citrate flue gas desulfurization (FGD) processes, assuming proven technology and using representative power plant, process design, and economic premises For each process, economic projections were made for a base case (500 MW, 35% sulfur coal, new unit) and DEFINITIVE SOX CONTROL PROCESS EVALUATIONS: LIMESTONE In order to eliminate the SO 2, the flue exhaust gases from a coalfired power plant are usually passed through a spray of limestone slurry in the scrubber The resultant reaction typically traps over 90% of the SO 2 Nearly 80%–85% of the global FGD units set up in power plants use wet limestone scrubbing compared to other technologiesDetermination of Flue Gas Desulfurization by Analyzing

Power, Ltd Flue Gas Desulfurization (FGD) Plants

The flue gas desulfurization (FGD) plant removes sulfur dioxides (SO 2) from flue gas produced by boilers, furnaces, and other sources Power effectively contributes to the prevention of air pollution through its wet limestonegypsum FGD process and seawater FGD process, and both processes can treat a large range of SO 2 Limestone Slurry Oxidation Air Sat Water Absorber Bleed Stream Flue Gas Water Vapor zScrubber Slurry Solids – Important WFGD process variable, verified daily with laboratory samples – Scrubber slurry solids: gypsum, limestone, flyash, inerts – Numerous inputs affecting water balance and solids concentration – Control solids concentrationWet FGD System Overview and Operation WPCAFlue gas desulfurization is a set of technologies used to remove SO2 from exhaust flue gases of fossilfuel power plants, as well as from the emissions of other SO2 emitting processes One of the most integral parts of the FGD process is that of pumped slurry applications, which contain fluid properties consisting of both abrasives and solids Slurry Applications in The Flue Gas Desulfurization Process

Flue Gas Desulfurization Upgrades and Life Extension GE

GE’s overall process expertise and assessment of current operation conditions will confirm any tuning needs for lime and limestone slurry preparation The quality of limestone and proper grinding level in the ball mill is very important for the most efficient SO2 removal Reduced operating costs can be observed by improving performance of Megawatts (MW) and whose Flue Gas Desulfurization devices have been operating for at least 5 years An analysis is made of the capital and annual costs of these systems using a comparison of four main processes: lime, limestone, dual alkali and sodium carbonate scrubbing The functional analysis, based on operability, allows a readjustment of theFLUE GAS DESULFURIZATION: COST AND FUNCTIONAL all power plants above 75 MW and discharging SO There are several types of wet flue gas desulfurization processes Three of the most common types employ lime or limestone, sodium alkali, or dualalkali Limestone slurry is fed into the main scrubber and a portion of the circulating slurry inpH Measurement and Installation Technical Paper Guidelines

Definitive SOx Control Process Evaluations: Limestone

EPA Number ECDP B4 DEFINITIVE SO CONTROL PROCESS EVALUATIONS LIMESTONE, DOUBLEALKALI, AND CITRATE FGD PROCESSES by S V Tomlinson, F M Kennedy, F A Sudhoff, and R L Torstrick Tennessee Valley Authority Office of Power Emission Control Development Projects Muscle Shoals, Alabama 35660 Interagency Agreement EPA D9E721BI (TV41967A) Program Oct 11, 2016 FGD systems are also used to reduce SO2 emissions from process plants, such as smelters, acid plants, refineries and pulp and paper mills In large power boilers, high temperature flue gases come in contact with lime slurry mists from atomizer wheels, or nozzle atomization arrangementsFlue Gas Desulfurization FGD Scrubber Maintenace GoodwayThis 2part article deals with the technical aspects of lime/limestone scrubbers for coalfired power plants Part I covers process chemistry and scrubber systems Part II (next month) will cover instrumentation, particulate removal, and sludge disposal Figure 1 is a schematic diagram of a typical lime/limestone based flue gas desulfurization JUNE 1980 CHNOLOGY News tandfonline

What Is Limestone In Power Plant Used

POWER PLANTS FGD LIMESTONE SLURRY PROCESSES POWER PLANTS –FGD LIMESTONE SLURRY PROCESSES NEW PROCESS TECHNOLOGY VS TRADITIONAL Pulverized Limestone w/ Vacucam® Ejector Mixers vs Crushed Limestone Wet Read more LIMESTONE POWER PLANT Jewett TX 75846